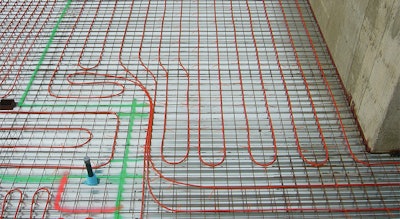

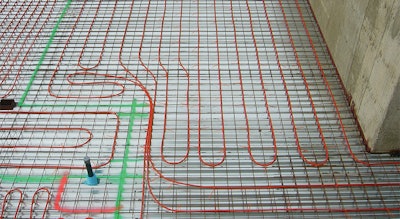

A roughed-in basement floor showing radiant tubes before the poured-in cement. Places where many tubes converge (oftentimes at doorways) can create hot spots in the floor. (Photo courtesy of Radiant Professionals Alliance)

A roughed-in basement floor showing radiant tubes before the poured-in cement. Places where many tubes converge (oftentimes at doorways) can create hot spots in the floor. (Photo courtesy of Radiant Professionals Alliance)

Radiant floors are not a new concept. They have been around for thousands of years, dating back to the ancient days of Rome, when Romans used systems known as hypocausts. In those applications, series of tunnels were constructed beneath the floor, a fire was started in an attached furnace and the heated (smoky) air wafted through the floor tunnels and the walls, radiating warmth into the dwelling or bathhouse. The use of hydronics (water-based solutions) came about much later, gaining traction in the early 1900s. Early systems utilized either steel or copper pipe for their in-floor distribution systems. In the early '70s, Europeans introduced a flexible plastic known as cross-linked polyethylene tubing, commonly known as PEX. This significantly reduced the labor associated with the delivery of radiant floor comfort, and it has been on the upswing ever since. Today, radiant heating is commonplace in markets across the country, oftentimes with wood flooring on top. What do you need to know to make sure you don't have a wood flooring failure when installing over radiant heat? First, let's examine the different types of systems in use.

Radiant configurations

Radiant floors come in a number of configurations. As you can see in the illustrations above, with these different systems, the tubing might be installed in concrete, in gypcrete or light cement overpours; in transmission plates below the subfloor; in engineered panels above the subfloor; or in suspended tube installations below the subfloor. Today we even have radiant walls and ceilings. Each method has benefits and limitations.

Understand R-value and temperature

One key to the excellent performance of these systems is to keep the resistance value of the finished flooring goods as low as possible due to flooring material conductivity as measured in R-value, or the material's resistance to heat flow. For example, a 3/8-inch-thick piece of ceramic tile will conduct heat at a higher rate than a thick carpet with pad. Hardwood flooring falls between these two, with an approximate R-value of 1 per inch of thickness.

The required floor surface temperature is dictated by the overall heat loss of the building the radiant system is being installed in, which can vary from room to room. A room with a significant amount of glass on exterior walls could require as much as 40 Btus per square foot per hour of conditioned space, whereas within the same building, the heating load may be as low as 10 Btus per square foot per hour of conditioned space in a room with no exterior glazing. For each 1 degree Fahrenheit difference in floor surface temperature versus room air temperature, each square foot of floor will deliver approximately 2 Btus per hour. So in the case of the highly glazed area, the floor would be required to have a surface temperature of 90 degrees Fahrenheit.

It should be mentioned at this point that although the floor heating elements (tubing, transmission plates, etc.) are very capable of handling these temperatures, it exceeds a critical factor that will cause human discomfort. Since human skin is normally 85 degrees Fahrenheit, when skin comes in contact with a surface greater than 85 degrees Fahrenheit, our brain thinks that our core is going to overheat, and it begins cooling our body by way of evaporation—sweating, basically.

Wood flooring's temperature limits

As a flooring contractor installing hardwood floors, you need to be aware of these potential issues, because although you are not responsible for system design or the delivery of the heat, the heat has to pass through your flooring to get to the room, and hardwood floors have some well-defined temperature limitations. Research has determined that wood stability is good below 80 degrees Fahrenheit surface temperatures, and unstable above 80 degrees Fahrenheit. This means the hydronic contractor is going to have to deliver the difference between what the floor is allowed to deliver when covered with hardwood flooring and what is required at design conditions. This is referred to as "augmentation heat." It can be provided with almost any proven hydronic method, including the addition of radiant walls, radiant ceilings, hot water baseboard or hydronic-powered forced air delivery methods.

RELATED: Avoid These Mistakes When Moisture Testing Wood Floors

Now, here comes the rub. Not all radiant floor contractors are aware of these hardwood floor limitations. It is important that you, the hardwood flooring contractor, become involved in the home comfort system design process early on to avoid issues with your hardwood flooring. One of your first questions should be, "What kind of heating system do you intend to install?" If the answer is radiant flooring, then you need to educate the consumer as to the limitations of certain hardwood species, the 80 degrees Fahrenheit floor surface limitation and the need for humidity control. If you don't, when things go south due to floor over-temperature conditions, the finger of blame may very well be pointed at you. If you are proactive, bringing these concerns to the consumer and radiant flooring contractor early on, problems can be avoided, and everyone will leave with a great feeling of cooperation.

Understanding humidity control

This engineered white oak split on its face after the radiant heat system was overfired above recommendations; additionally the relative humidity had plunged to below the flooring manufacturer's requirements. (Photos courtesy of Roy Reichow)

This engineered white oak split on its face after the radiant heat system was overfired above recommendations; additionally the relative humidity had plunged to below the flooring manufacturer's requirements. (Photos courtesy of Roy Reichow)

When I say "humidity control," I am not referring just to the addition of humidity, but in certain cases the removal of humidity in order to maintain the conditioned space within the ideal range for a given wood species. This is another question that must be asked early on in the planning process, and if the answer is unclear, then you must let the consumer know that it is extremely important for maintaining wood in good condition.

RELATED: Can We Be Proactive in Preventing RH Problems for Wood Floors?

Again, although humidity control is not your responsibility, your wood products will be negatively affected if it is not addressed. I strongly recommend these caveats become a part of your contractual proposal, and that the consumer be asked to acknowledge these critical needs and limitations. This way, if someone forgets to address these critical requirements, you have proof that it was brought to their attention and that you have done your best to educate the consumer.

What to know about electric radiant heating

Another area of concern is the use of electric radiant heating elements with hardwood floors. Electric radiant floors come in numerous configurations. Some are as simple as a single heating element, which is stapled to the subfloor, covered with a cementitious material and finally covered with the finished flooring goods. The energy intensity of this type of heating element is relatively high in the immediate vicinity of the heating element. Depending on the thickness of the cementitious materials, the energy density can be dispersed prior to coming into contact with the finished flooring goods. The thinner the substrate, the higher the surface temperature immediately above the heating element.

There are also numerous plastic sheet elements that do an excellent job of dispersing the energy over a significantly larger area. This results in a lower watt density, which equates to a more consistent and lower surface temperature.

Again, as you are in the process of discovery, if you find your customer intends to install radiant floors, your next question should be, "Electric or hydronic?" If the answer is electric, you will be way ahead by recommending the use of a plastic sheet element, and also by making certain that the wood flooring manufacturer allows installation over an electric radiant floor. Once again, get the consumer's affirmative acknowledgement of your recommendations.

Energy intensity of hydronic systems

This engineered product is a structural flooring element with a highly conductive aluminum face that spreads out heat, helping avoid hot spots. (Photo courtesy of Warmboard)

This engineered product is a structural flooring element with a highly conductive aluminum face that spreads out heat, helping avoid hot spots. (Photo courtesy of Warmboard)

Hydronic systems can also have a high energy-intensity factor. Tubing embedded in a cementitious material will have a lower supply water temperature than exposed tubing in a floor joist bay. It is now a requirement that a control device that modulates the supply water temperature commensurate with the outdoor air temperature is included in the boiler package. But to be effective, the control must be properly programmed. Make certain that the mechanical contractor has enabled this feature of the boiler, and that it is set as low as possible. Hydronic contractors have a tendency to err on the high side, as all contractors do.

Done correctly, radiant floor heating systems and hardwood floor coverings can work together seamlessly. I have more than 250,000 square feet of it in the field, and have only had one problem that wasn't related to the heating system installation (in that case, errant nails punctured tubes). Done incorrectly, many fingers of blame will be pointed in many directions, and the consumer usually ends up with the short end of the stick. Education is the key to success. Knowledge is power, and we all need as much of that as we can possibly garner.

8 questions to ask before a radiant heat job1) Will you be using an electric or hydronic radiant system? 2) If electric, will you be using a plastic sheet element? Using one disperses energy for a lower and more consistent surface temperature. 3) What species is specified? Safest bets are species that tend to be more dimensionally stable. American cherry, American walnut and American oak, for example, will tend to show gapping and cupping less than species such as maple and Brazilian cherry. 4) What cut is specified? Riftsawn and quartersawn cuts are the most stable. 5) What width is specified? The narrower the board, the less apparent the changes in width. 6) Does the wood flooring manufacturer warrant their flooring over the type of radiant heat being used? In particular, some engineered wood flooring manufacturers won't warrant their product over electric systems. 7) What humidity controls will be in place? Just as with every wood flooring job, the floor will perform best if it is kept within its comfort zone, typically around 35–55 percent relative humidity. 8) What temperature will the system be set at? Surface temperatures over 80 degrees Fahrenheit are considered too hot for wood flooring. |

Common radiant pitfallsHere are some tips from an inspector—Roy Reichow of National Wood Floor Consultants—who has inspected many wood floor failures over in-floor heating systems: • Before the installation, request the system design and look for the manifold area (where everything comes together). This is the hottest part of the floor due to concentrated supply temperatures and generally runs 5 degrees or more hotter than the rest of the floor. If your wood flooring runs over this area, you might not be able to warranty it because of excessive heat. • Watch out for different floor coverings in the same radiant zone, because they have different R-values. The R-value for carpeting is twice that of hardwood, so a family sitting in the carpeting living room watching TV may turn up the heat, overheating the hardwood in the kitchen next door. • Underlayment pads that go under floating floors can have a huge difference in R-values, so it's important to know the R-value of the entire floor system you will use. If the system is designed for an R-value between 1.5 and 2 but all your flooring components are between 3 and 5, you'll create a heat deficiency. • If you cover the wood flooring after installation during construction, be sure to use a cover with a low R-value and high perm rating to allow humidity and heat to pass through. • Customers should understand the correct "setpoint" for their thermostat. With forced heat systems, most people set it between 68 to 72 Fahrenheit, but because in-floor heat systems conduct heat differently, typically their setpoint should be between 65 to 67 degrees. If consumers aren't aware of that, they can over-fire the system (see the photos on page 46). • Different types of in-floor systems have different supply temperatures. For example, staple-up systems have a higher supply temperature than hydronic/gypsum systems, which can make staple-up systems less friendly for wood flooring. |