Have you ever come across a situation like this? Here it is:

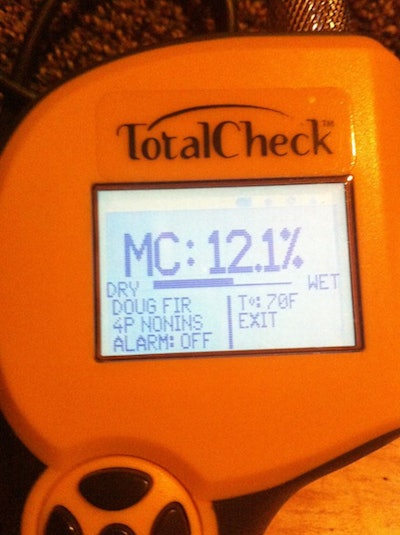

The flooring contractor was waiting for the subfloor moisture content (MC) to decline before proceeding with a plank floor installation. There were many areas within the subfloor ranging from 11 to 13% moisture content, with ambient conditions ranging from 42 to 48% RH and 72 degrees F. The plank wood floor MC measured 6 to 7%, meaning that per the Installation Guidelines the subfloor MC range need to be between 8 to 9%, not 11 to 13%.

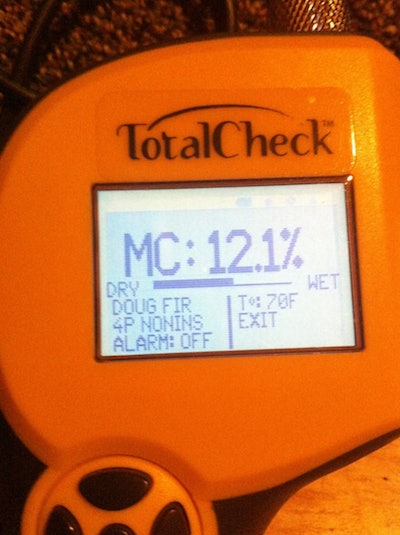

Here are the readings:

Moisture readings: As you can see in the photos above, moisture measurements were obtained using two different types of moisture meters and, for the most part, were reasonably accurate. It's interesting to note that the remodel project had been under close moisture control using commercial dehumidifiers and air conditioning. The existing hardwood and millwork MC ranged from 7 to 8%, which would be considered normal levels for this time of year. With the "normal" EMC of the woodwork in the residence, it didn't make any sense that the plywood was holding more moisture than the other wood in the home.

Destructive Testing: A 6" x 6" square was removed in the plywood subfloor and MC was retaken. This time moisture measurements were obtained in the core of the plywood and between the glue lines, and the core MC was in the normal range of 6 to 7%, which is in the EMC baseline of the home. Here are the photos:

Solution: Never assume all things are equal, including moisture readings. We must remember moisture meters provide an indication of moisture levels, and an installer or inspector must look at all possibilities. In this case, the glue used in fabrication of the plywood subfloor skewed the moisture measurements results. It's always important to pay close attention to moisture levels when taking a gradient reading and the relationship of the glue lines. If there is no jump in readings, most likely the glue has no effect on the meter, however if it does, then a core sample is the best confirmation. This could also apply to core materials of engineered flooring or microlams, as well.