Q: Which types of subfloors are acceptable for engineered hardwood flooring?

Engineered wood can be glued, nailed, stapled, and some can even be floated—depending on the subfloor. It goes down easily over concrete, plywood, OSB and underlayment-grade particle board. Or, you can install it on top of existing floor coverings, such as vinyl, terrazzo, ceramic, cork or existing wood flooring. Engineered wood also can be used on-, above- or below-grade.

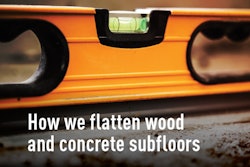

The prep work for laying engineered hardwood flooring varies depending on what's under it, but any subfloor needs to be flat (within 3/16 inch in a 10-foot radius, or 1/8inch in a 6-foot radius); structurally sound and clean; and free of dirt, paint, drywall patch and other contaminates. Below are some common subfloors and—generally speaking—the kind of prep usually done for each. (Always check with your flooring manufacturer for specific guidelines.)

Concrete. The mix must be structurally sound (at least 90 to 100 pounds) when gluing down wood flooring. Some manufacturers recommend a topical sealer/bonding agent that allows for installation of glue-down engineered wood over lightweight concrete. You can install floating engineered flooring over lightweight concrete. The concrete must have cured for at least 60 days and must be dry. When using a calcium-chloride test, results should be 3 pounds or less. If using a moisture meter, refer to the flooring manufacturer's guidelines for acceptable meters and readings.

Plywood. It must have a minimum 5/8-inch thickness. For square-edge plywood, 3/4-inch is required,usually CDX grade or smoother.

OSB. This must be 3/4-inch tongue-and-groove, APA rated, underlayment-grade OSB. Check with the flooring manufacturer about using OSB. The wax side must be down for glue-down flooring applications.

Particle board. This must be APA-rated performance standard and stamped underlayment grade, 40-pound minimum. Flooring should be glued—not stapled or nailed—but can be floated.

When considering your subfloor, also think about the joists. The industry standard for hardwood floors over joists is 16 inches o.c. and for floor truss systems, it's 19.2 inches o.c. Consult the manufacturer, NWFA or NOFMA recommendations if joists/trusses are at a wider distance than recommended. This is not to say that you cannot install over a wider width,but the performance of the flooring may suffer due to interior deflection in the subfloor. You may avoid this by adding subfloor material to increase it to a minimum total thickness of 1 1/8 inch.

As I mentioned above, installation on top of existing floors also is very common with engineered wood. Here are a few existing floors over which we regularly install engineered hardwood.

Vinyl, VCT, linoleum. These coverings must be firmly adhered and bonded to the subfloor beneath;perimeter-glued vinyl must be removed if the new flooring will be nailed, stapled or glued down. Any waxes or topical coatings must be removed. It's alsoa good idea to lightly sand to achieve a good mechanical bond. Remember, any vinyl flooring manufactured prior to 1990 could contain asbestos. In that case, do not sand it. Consult the proper authorities or agency for regulations and proper procedures for asbestos abatement.

Marble, terrazzo, ceramic tile. These types of existing flooring must be sanded with 20-grit open coat sandpaper prior to gluing down wood flooring. This will help achieve a proper bond to the existing floor or flooring.

Existing wood floors (on- or above-grade only). Old finish and high spots must be sanded off; any loose planks should be nailed down. The new floor must be laid at a 90-degree angle to the old flooring. If that can't be done, 3/8-inch or 1/2-inch plywood can be installed on top of the old flooring, leaving a minimum 1/8-inch gap between each plywood panel to accommodate expansion from heat and moisture, and the new flooring can be laid in any direction.

Radiant-heated subfloors. Most manufacturers allow for floating floors over radiant-heated subfloors, but check the individual flooring manufacturer's recommendations. The industry guidelines can be found on the NOFMA or NWFA Web sites or in the manufacturer's installation manual.

Cork underlayment. Most engineered flooring can be glued down or floated over properly installed cork underlayment (used for sound absorption). Refer to the manufacturer's guidelines on installing the cork and wait three to five days before installing the wood flooring. This allows the adhesive bonding the cork to the subfloor to cure properly.