The Problem

I was commissioned by a central Indiana homeowner to inspect a 1,500-square-foot main level hardwood floor showing generalized cupping two months after completion of the new home.

The Procedure

The ¾-by-3¼-inch solid red oak was nailed down over a full crawl space. Interviews with the dealer and wood flooring installation contractor revealed no examination of the crawl space had been made prior to wood flooring delivery. Acclimation took place within HVAC living conditions, but moisture readings were not documented.

The Cause

The main level revealed hardwood flooring moisture content (MC) averages of 9.7% to 11.3%, taken from depths of ¼, ½, and ¾ inch, in six separate areas throughout the main level. With indoor ambient readings in all rooms averaging 72°F and 44% RH, I knew the crawl space would provide critical information to explain why the cupping occurred.

As I entered the crawl space, my glasses fogged up immediately. While it was 34°F outside, the crawl space was a balmy 74.8°F, with RH readings topping out at 69.7%. A 6-mil polyethylene vapor retarder was in place over the pea gravel but fell short of the perimeter block walls and interior block stems by as much as 1-3 feet. No perimeter ventilation openings existed, but HVAC duct work did. There were small water puddles underneath various water return lines from the condensation dripping. The subfloor underside MC averaged 16.9%; the high reading was 18%. The evidence was overwhelming: Damp conditions with no cross ventilation allowed for unabated vapor absorption into the subfloor above. Cupping was an unavoidable result in this uncontrolled environment.

How to Fix the Floor

The MC differential from the top of the wood flooring board to the bottom needs to be within 1% and (in this area) between 6% and 9% overall. Only then should sanding be considered; full replacement may still be necessary.

The source of the moisture must be corrected before dealing with any cupped floor. Crawl spaces must be dry and should be a minimum of 18 inches from ground to underside of joists. Crawl space earth or gravel should be covered 100 percent by a 6-mil (minimum) vapor retarder of black polyethylene. Vapor retarder joints must overlap a minimum of 6 inches and be sealed or taped. It should also extend at least 6 inches up the block walls and stems and be attached and sealed to them. Where a proper vapor retarder is in place and when venting is required by local building codes, the crawl space should have open perimeter venting equal to a minimum of 1.5 square feet per 100 square feet of crawl space square footage, unless local building codes state otherwise.

Because this crawl space had no ventilation openings, continuously operated mechanical exhaust should be considered. Thermostatically controlled power ventilators mounted inside of multiple perimeter openings can control elevated temperature and RH conditions, and permanent high-capacity dehumidifiers are another option. Sensitive water lines and pipes should be insulation-wrapped as needed. Sump pumps are wise investments to handle heavy rains and snow melts.

In the Future

Because crawl spaces are considered part of the job site building envelope, they must be thoroughly inspected and moisture conditions within them stabilized before wood floor delivery or installation. This is not an option.

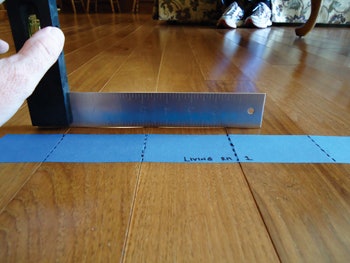

See photos from this inspection:

Crawl space hygrometer readings were 74.8°F and 69.7% RH. The clear 6-mil polyethylene vapor retarder is visible.

The crawl space subfloor underside MC measured 18.0%.

Cupping resulted when the bottom of the wood floor had a higher MC than the top.

The cupping may relax some if the crawl RH can be lowered quickly.

The crawl space vapor retarder had large openings, permitting entrance of subsoil moisture.

Moisture condensation on cold water lines was observed dripping onto the vapor retarder.