All images courtesy of Bozovich Timber.

All images courtesy of Bozovich Timber.Tropical hardwood flooring is increasingly popular, but not many people are aware of the lengthy, difficult process involved in getting this product from its source in the rainforest to the end user. At the same time, when considering using tropical species, people are often concerned about the destruction of the rainforest. Here's a behind-the-scenes look at how the company I work for-Lima, Peru-based Bozovich Group-handles the process of getting tropical flooring to market, from using sustainable forestry practices to shipping the product safely to the United States.

Cumaru logs can be from 10 to 24 feet long and weigh up to five tons each.

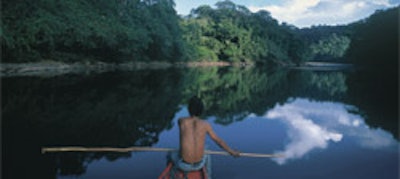

Cumaru logs can be from 10 to 24 feet long and weigh up to five tons each.Cumaru (Dipteryx spp.) grows in Costa Rica, Panama, Venezuela, Colombia, Brazil, Bolivia and Peru, which is where Bozovich sources it. Cumaru trees are large overstory trees that can grow up to 160 feet tall. Like other species, they are scattered throughout the forest. In fact, there are on average over 100 different timber species per hectare (equivalent to 2.5 acres) and over 3,000 botanically recognized timber species in the Peruvian rainforest. Because of the diversity of the forest, the average number of trees sustainably harvested in the Peruvian jungle is one tree for every 2.5 acres (clear-cutting is not used). Only a small portion of the Peruvian rainforest can be utilized for harvesting. About 40 percent belongs to native communities, about 35 percent belongs to the National System of Protected Areas (parks, reservations, historical or scenic sanctuaries) and approximately 25 percent belongs to Forests of Permanent Production, where private forest businesses can have access with a legal authorization for a forest concession if they meet all the government requirements.

All wood species are determined before a cutting plan is determined.

All wood species are determined before a cutting plan is determined.The process of selecting cumaru trees begins with planning based on sustainable forest management principles as outlined by the United Nations' Food and Agriculture Organization. The General Forest Management Plan from the Peruvian government gives information to develop strategic management and long-term projections for the utilization of the forest during the period of the concession. At this point an inventory of the whole concession is done to determine the volume of permissible use. Soil and hydrology conditions are also studied to provide the necessary information for harvest strategy, road planning, etc. Once the potential use of the concession is determined, a Five-Year Plan is made. This plan checks closely for many things, including high conservation values (HCV), which can be environmentally based or culturally based. One example is the endangered Peruvian bald eagle, which only nests in certain tree species; those species are identified and avoided.

In the past, barges were often used to transport the logs by river, but now roads are the main means of transportation.

In the past, barges were often used to transport the logs by river, but now roads are the main means of transportation.The Five-Year Plan area is divided into five parcels that will be worked on a yearly plan-the Yearly Operative Plan, or POA (its initials in Spanish). In this plan, 100 percent of the trees are located using a GPS system. Every tree is codified. Seedlings and minimum diameters for harvesting are respected, and the goal is to harvest the small percentage of older trees that are already in the end of their life cycle. The cumaru trees suitable for harvesting are cut into logs with chainsaws and transported by specialized mechanical equipment following principles and guidelines of Reduced Impact Logging from the Tropical Forest Foundation (TFF).

Cumaru often grows in areas that flood during the rainy season. Because of this, harvesting is done only in the dry season, from June to November. Trying to operate in the rainy season would destroy roads and equipment. It is difficult enough to operate in the dry season where, in addition to poisonous snakes, malaria, yellow fever, and biting insects, the temperature ranges from 85 to 100 degrees, and the humidity averages over 90 percent. Some logs are stored in the dry season so that the sawmills can continue to saw the logs during the rainy season, creating continuous flooring production.

Logs are measured to determine cuttings.

Logs are measured to determine cuttings.After leaving the kiln, the blanks are graded and enter the flooring factory, which is equipped with high-quality German machinery. There, they go through several processes, starting with the moisture content control, then into the planer and optimizer, and finally the molding machine and the end-matcher, where they will emerge as the tongue-and-grooved four-sided product. Much of the quality control and grading of the product is done at this point.

Next, the flooring is banded together in mini-bundles according to the width. The product is covered with a stretchy transparent plastic wrap to protect it from humidity, sunlight and dust. All bundles are stored in a warehouse until shipment. The bundles are then loaded in 20-foot ocean containers at the main Bozovich yard in Lima, Peru. Consolidation of containers is done by a specially trained crew; Bozovich is a certified member of the worldwide organization Business Alliance for Secure Commerce, which was created to promote supply chain security in cooperation with government agencies and international organizations, including U.S. Customs and Border Protection.

A warehouse where lumber is stored on sticks for drying.

A warehouse where lumber is stored on sticks for drying.The paperwork and documentation involved in exporting and importing flooring is coordinated by personnel in Peru and at Bozovich's North American headquarters in Evergreen, Ala., for Lacey Act compliance. (Paperwork is also involved for FSC compliance-Bozovich offers some FSC-certified lumber and hopes to offer FSC flooring in the near future.) The culmination of all the hard work means that when customers choose the right exotic product, they get a product that is not only beautiful, but also environmentally sound.