All hardwood flooring is not created equal. From the tree and how it's grown, to where it is sawn and dried, to how it is manufactured, there are many important aspects that differentiate the end quality of the hardwood flooring. This article will highlight the various sawing methods that create many flooring options even with the same species of tree. The way the wood is cut affects how it is dried, how it will look as flooring and how it will lay in the home once it is installed. These differences can make a huge difference in the satisfaction of the homeowner.

Flooring Cuts

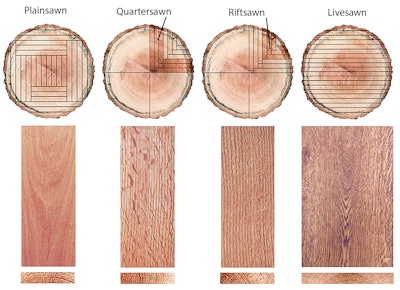

There are three well-known cuts from which flooring is made. The most popular is plainsawn, also known as flatsawn. Next we have riftsawn and quartersawn, which are different, but often sold together as rift and quartersawn (R&Q). A new trend is livesawn. It is a mix of R&Q and plainsawn, and to fully understand livesawn, it is important to have an understanding of plainsawn and R&Q.

Hardwood flooring, like everything in interior design, has different stages of style and fashion changes. Plainsawn is the most common cut today, but prior to the early 1900s, quartersawn was all the rage due to its fashion and functionality. However, plainsawn developed and could be sawn more efficiently than quartersawn flooring, and it became commonplace. At that time, logs were quartersawn in a manner that produced 100 percent quartered lumber, which was very wasteful. Today's R&Q is cut to produce minimal waste, but its overall production takes longer than plainsawn products.

It is easy to tell the difference between a plainsawn board, a riftsawn board and a quartersawn board.

Plainsawn:

The end grain of a plainsawn board has annual growth rings between 0 and 35 degrees. The face of the board has what is referred to as a "cathedral" grain pattern. Most old homes built in the early and mid-1900s had 2- to 3-inch plainsawn red oak, and when people think of oak floors, this is what they picture.

There are four ways that wood flooring can be cut from the tree; the cut used affects appearance and performance.

There are four ways that wood flooring can be cut from the tree; the cut used affects appearance and performance.

Quartersawn:

When the log is cut into quarters to make quartersawn boards, the annual growth rings are at 90 degrees to the surface. White oak is especially popular in quartersawn because of the vibrant ray flecks along with the tight wavy grain pattern create a really cool and elegant look. The fleck is caused by the medullary rays, which are the life veins of the tree. The medullary rays are perpendicular to the annual growth rings and therefore parallel to the surface of the quartersawn board. These rays are very pronounced in the white oak and it creates this great figure.

Riftsawn:

This cut has annual growth rings angled around 45 degrees, and the grain pattern on the surface is very lineal. It's important to note where the riftsawn boards come from in the log. When a log is quartered, it is then cut from the center face and works its way out. The boards that come from the outside edges have 45 degree annual growth rings. This comes from the smaller part of the quartered wedge. If you picture this, you can see why it is hard to get wide-plank rift only!

In fact, a few years back we had an experienced installer who was looking for wide-plank rift-only white oak. When told how difficult it was to get, he said to our owner, "You own a saw mill! Why can't you just cut it?!" We invited this installer to the sawmill while we were cutting R&Q white oak and asked him to watch to see how many wide-plank rift-only boards came through. After an hour, he realized he had not seen a single one wider than 4 inches!

When Moisture Comes & Goes

As we all know, wood is hygroscopic, meaning it shrinks or swells depending on the moisture levels. Below you can see the directions of expansion and contraction in the different types of cuts as they gain or lose moisture. Because of the direction of the growth rings, plainsawn boards change in dimension across their width, and the wider the board, the more the potential for dimensional change. Quartersawn and riftsawn boards, on other hand, change in thickness.

How These Cuts Behave

The angle of the annual growth rings changes the look of the floor, and it determines the dimensional properties, as well. Wood will either shrink or swell depending on the moisture gained or lost. The direction of the movement is determined by the annual growth rings. Plainsawn boards will expand and contract through the width of the board. The wider the plank, the more potential movement. Riftsawn and quartersawn has movement through the thickness of the board. Therefore R&Q flooring is a smart decision for stability. For example, it can be installed as a solid ¾-inch-thick plank board over radiant heat.

How the Lumber is Dried

The drying of lumber is one of the most important parts of how a hardwood floor lays in a home. It may not be the most sexy or fun part of picking out a new floor; in fact, by just looking at a board you have no way of knowing if it's been dried properly or not. But, it is absolutely critical to the stability and quality of your floor to begin with a properly dried piece of flooring.

To understand the drying process of wood, you have to understand the anatomy of a tree. Trees have medullary rays that are basically the veins that transport the nutrients while it is a standing tree. When the tree is cut into lumber, the medullary rays are visible. White oak is a great example to look at because its medullary rays are more pronounced. These rays are perpendicular to the annual growth rings. If you think of a standing tree, you can visualize the growth rings growing around the trunk parallel to the ground and the medullary rays flowing vertically up from the roots to the leaves.

Let's move from the forest to the sawmill, where the logs are cut into lumber. There are different ways these logs can be sawn, as I discussed earlier. With quartersawn lumber, the growth rings are perpendicular to the surface and the medullary rays are parallel to the surface. The fleck you see in quartersawn is from the medullary rays.

Moisture moves out of the lumber through the medullary rays, so plainsawn and quartersawn wood dry differently. In plainsawn, the medullary rays are perpendicular to the surface, so moisture moves out through the thickness. In a 4/4-inch piece of lumber, moisture from the center only has to move ½ inch from the center out of the board, allowing the lumber to dry more quickly than a quartersawn piece of lumber. Moisture in a 4/4-by-6-inch quartersawn board has to move 3 inches from the center. It's pretty obvious why this will take longer to dry.

Unfortunately, many sawmills are not set up to cut specifically for R&Q. If plainsawn boards and R&Q are all dried in a kiln together, the boards will not be dried equally or correctly, and they will end up with different core Moisture Content (MC) levels.

The core of a board dries at a different rate than the outside. This is why it's important to do constant monitoring and various testing throughout the drying process.

Livesawn

This random-width white oak floor was livesawn and also shows circle saw marks.

This random-width white oak floor was livesawn and also shows circle saw marks.

With this in-depth understanding of the difference between plainsawn, riftsawn and quartersawn, we can discuss livesawn, which is a mixture of these three cuts. Livesawn is cut straight through the log. You can see how the growth rings work their way out from parallel to the surface in the center to perpendicular to the surface on the edges. As you can imagine, the drying process requires extra attention due to this variety. However, it does create a very stable floor because it results in a high percentage of R&Q boards. Many people find wide-plank livesawn a spectacular look because it allows for more of the quartersawn and fleck in each board. The wider the plank, the more the natural beauty and larger knots can be represented in the floor. The end result is a unique floor that incorporates all the natural characteristics of the tree and wastes little in the process.

Hopefully this helps you understand the difference between the different "sawns" available and how they will act when installed in a home. Each hardwood flooring board has a life story, from its life growing in the forest through the sawmill and manufacturing process. No two boards will ever be the same, and the feeling you get from a quality hardwood floor cannot be replicated. This is why so many of us choose to work with wood floors for a living, and this the beauty of hardwood flooring.