Every trade has its own set of must-have tools, and wood flooring is no exception! In this article we'll be diving deep into what I consider the must-have (and a few nice-to-have) saws for installation. I'm going to attempt to stay brand-neutral, and rather focus on types of saws here to prevent ruffling too many feathers.

1) Miter Saw

Having a laser line is one useful feature you'll find when you pay a little bit more money for a miter saw.

Having a laser line is one useful feature you'll find when you pay a little bit more money for a miter saw.

I find that a sturdy stand with extension arms is essential for supporting long boards. (Photo courtesy of Ron Begg Jr.)

I find that a sturdy stand with extension arms is essential for supporting long boards. (Photo courtesy of Ron Begg Jr.)

First up to bat, the miter saw. The options are seemingly endless, along with different preferences from different pros. Here's what the language with these saws means:

Miter: The ability to turn the blade at an angle other than 90 degrees from the fence.

Single-Bevel: The ability to cut a compound miter by tilting the saw blade to one side.

Double-bevel: The ability to tilt the saw blade to either the right or left.

Sliding: These saws have rails that allow you to pull the blade forward and backward to accommodate cutting wider material.

Compound: This refers to the saws ability to cut angles in more than one direction at once (i.e. compound miter cuts).

Blades

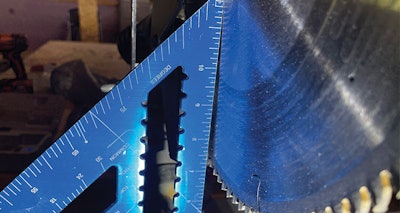

There are 10-inch, 12-inch and even some 71/4-inch options when it comes to blade size.

One thing to consider when buying a blade is the kerf. The kerf is the thickness of the carbide tips and determines how much material will be removed when cutting. Thicker kerf blades are typically more expensive, and the blade itself is also usually thicker, making it more stable and less likely to warp. When I invest in this type of blade, I save them once they are dull (as long as they still have all their teeth) and have them resharpened. Oftentimes, when the blades come back from being sharpened, they are better than they were when new!

You can spend a lot on a blade and dull it up rather quickly depending on what it is you're cutting. Some flooring materials like laminate and even some LVP can quickly dull the blade. In cases like this, or for general cutting, I prefer to use a less expensive blade. You can also purchase special blades for laminate that will last longer, but sometimes three cheap blades cost the same and last just as long or longer.

What I use

In my opinion, the largest and most useful option is the double-bevel sliding miter saw. I prefer the 12-inch size, because you never want to bring too small of a saw to the party, right? For your everyday installations, this saw is your main workhorse. It's also big enough to be able to cut stair treads or newel posts and handle most wide plank. Having the sliding option really helps to be able to line up out-of-square cuts, and if your saw is equipped with an LED shadow line or laser line option, all the better.

The smaller saws are great to have as a backup or for small or multi-level work, and some of the cordless options are super handy for when you show up to the job site to find four different trades all sharing the only two live receptacles in the whole house.

We prefer to have a sturdy stand with extension arms that can support long boards. Some stands also have wheels, which make bringing your saw in and out of the truck and onto the job site easier. Most stands are universal and will fit multiple brands of saws.

You get what you pay for

When it comes to the miter saw you choose, you get what you pay for. Most tools come in three categories:

1) cheap homeowner weekend-warrior model

2) mid-grade

3) pro-grade.

Buying the most expensive isn't always necessary, but I would avoid getting the cheapest, as well. Most mid-grade or pro-grade saws have a built-in LED for a shadow line or a laser to show you where you'll cut, and sometimes they even come with a stand. Dust collection is another feature that is often better-thought-out on the more expensive brands.

Two don'ts: Never wear gloves while cutting with a saw, which could entrap your hands, and don't hold a short piece close to a cutting blade

Two don'ts: Never wear gloves while cutting with a saw, which could entrap your hands, and don't hold a short piece close to a cutting blade

How to be safe with a miter saw

There are some common mistakes I see with people who are unfamiliar with using a miter saw. One is plunging the blade in before it's spinning at full speed, and another is cutting something that's not secured tightly against the fence. Oftentimes the piece they are trying to cut is too small, and they end up not holding it well due to the fear of being so close to the blade.

When someone makes either of these mistakes, the saw creates a telltale sound that stops me from what I'm doing to make sure the person who is cutting still has all their digits. Take the time to be safe, make sure you wear safety glasses and hearing protection, and don't try to cut a small piece unless you have it clamped with something other than your fingers.

How to adjust your miter sawWhen just making simple end cuts you may not notice if your saw is cutting out of kilter, but when it comes to precise miters and other cuts that intersect, having your saw dialed in makes a world of difference. Because we load our tools in and out of vehicles and from job site to job site, it's quite common for them to get out of square. Here are some quick tips to get everything back in order again, and shouldn't take more than a few minutes at the beginning of each job. (For table saw tips, scroll down).

The detent plate on your miter saw, shown at left, is what helps you determine the angle of the blade in correlation to the fence. One way to prevent it from getting out of whack is to lock it when in transit when it's between detents (e.g., 30 degrees). Bumping the arm while in a detended position is what makes the detent plate move and change position.

I like to use a steel framing square against the fence and check the blade against the fence when it's down and locked in the zero position.

If you've got a sliding miter saw, slide it back and forth and check that it's tight to the square at both locations. Here you can see it's showing out of square—the blade is over the top of the square. Remember that when you push the blade down to touch the square, the carbide tips of the blade are wider than the body of the blade, so check those tips, not the blade itself.

If it's out, loosen the detent plate and move the saw until it's square with your framing square. Once it's lined up, tighten down all the screws that hold the detent plate and you're done! Make sure that the indicator is pointing to zero, and if it's not, adjust it.

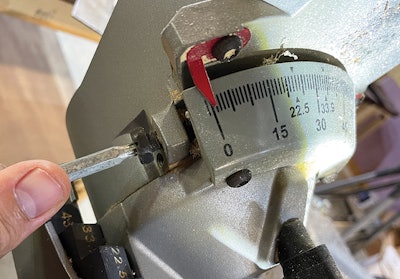

If you have a compound miter saw, check that the tilting position is square using a speed square as pictured here.

Your saw should have a bolt that's used to create a hard stop position for zero. Sometimes dust can get jammed in there, causing it to stop before it's really at zero, so there's my plug for keeping your tools clean! If the blade isn't square from the center to the edge, adjust that stop until it is; then you can also adjust the indicator to the zero mark.—K.N.

|

To be safe, always use hearing protection, eye protection and a push stick with your table saw (photo courtesy of Dustin Bolin).

To be safe, always use hearing protection, eye protection and a push stick with your table saw (photo courtesy of Dustin Bolin).

If you spend more for a quality table saw, you'll have grooves that allow you to use sleds, such as this one by Rockler, or you can make your own sled to create custom parquets or medallions.

If you spend more for a quality table saw, you'll have grooves that allow you to use sleds, such as this one by Rockler, or you can make your own sled to create custom parquets or medallions.

2) Table saw

From rips to plunge-cutting vents, the table saw is next on my list of must-haves. The options in this category are not as overwhelming as the miter saw, as the biggest difference you'll find is the inclusion of a portable stand and differences in fence styles. There are some table saw brands that even have blade-stopping technology onboard for safety, which is a huge plus! (If you don't agree, just talk with someone who has had a saw injury and get their point of view.) Getting a higher quality saw that has miter grooves on the top will allow you to make custom sleds for on-site milling of patterned floors.

How to be safe with a table saw

Table saws are probably the most dangerous among the tools we use. To stay safe:

- Keep your hands in front of the blade.

- Make sure the blade is sharp.

- Don't use the saw with the blade higher than necessary. Try to keep the blade height slightly above the material you are cutting—this creates less stress on the blade and fewer opportunities for it to come into contact with something other than what you're cutting.

- Use a push stick, especially when making cuts without the fence.

- Use the riving knife, which is the metal hook-shaped attachment that mounts behind the blade. The riving knife is there to prevent material from binding on the blade and kicking back at the operator.

- Pay attention to the task at hand when cutting. Getting distracted by things or people around you on the job site, your cell phone or your smart watch could cost you some fingers or worse.

- Never wear gloves, loose sleeves or dangling jewelry while running the table saw.

- Unplug the saw any time you change a blade.

- Keep the tabletop clean.

Most saws also come with an anti-kickback attachment, but these are often cumbersome and are the first thing to be taken off or thrown away. If you are going to spend extra money on a tool, this is one where buying one with blade-stopping technology is worth it. Sawstop, owned by Festool, makes this saw in both a portable version and a shop version.

How to adjust your table sawAs we mentioned in the miter saw adjustments sidebar on page 38, it's incredibly important that you check your saws to make sure they are cutting true. Here are some tips for table saws:

With your table saw, the main culprit for problems is usually the fence being out of square with the blade. To check it, I use a steel framing square and place it between the blade and the fence and lock the fence down about 1⁄8 away from the square. (Adjust the blade height to be sure the square is touching the blade on both sides and not the carbide tips.) Be sure you are using a good new blade or one that you're positive isn't warped; you can check by laying it on a flat surface. If the fence is out of square, you should be able to see it using a straightedge as seen here. (It's touching on one side but not the other.) Adjust it by loosening the fence bolt and tightening it back up once it's square. A small discrepancy makes a big difference when you are doing precision work, and can also cause the wood to bind between the blade and fence.

On my saw, this is where you loosen the fence to adjust it. The bolts etc. will be slightly different on each saw, but you get the idea and can always refer back to your user manual for details on your saw.

The other thing to check is that the zero on the bevel setting is square. You can check this by using a speed square on the table with the blade all the way up or you can use a digital angle finder. The stop for this can also get easily jammed up with sawdust, so make sure it's clean before you adjust the stop (in the photos here, the center one shows the adjustment as seen from the outside of the saw, and the one on the right shows the inside view). Now that your tools are all squared up, making those perfect fireplace miters will be easy peasy. Cheers!—K.N. |

Photo courtesy of Jessica Colpron

Photo courtesy of Jessica Colpron

3) Oscillating saw

Third in my book is the oscillating saw. Originally patented and owned by one company, Fein, now it seems every brand has their own version, and cordless options are prolific. These saws are great for cutting door jambs, doing lace-in repairs, finishing flush-mount vent cuts, trimming cut boards to the final dimension ... you name it!

The saw is only as good as your blade here, and if you apply direct pressure without any rocking motion to remove debris, prepare to set the smoke alarm off! You can spend anywhere from $1 to $15 for one blade! Some pros prefer to buy the cheap ones in bulk and toss them as they go, while others like to spend more on good blades that last longer. Some blades are made for only cutting wood, while others are able to cut wood or metal. Better still, they even have carbide-tipped blades that will cut hardened-steel-like screws, which can come in handy from time to time.

These saws have multiple attachment options, as well, which makes them useful for detail sanding, or working with mediums other than wood, like removing grout from between tile or cutting steel. Some brands feature a built-in light, which I personally think should be on every tool these days.

How to be safe with an oscillating saw

Stability is key with this saw. Keeping a steady hand is paramount, and using sharp blades will prevent the material you're cutting from burning and overheating the blade.

Photo courtesy of Joe Smith

Photo courtesy of Joe Smith

4) Track saw

Number 4 on my list is the beloved track saw—a circular saw that runs on a track. Track saws have the unique ability to make depth-set plunge cuts and perfectly straight cuts, as they run along the track system. There are multiple brands that make these specialty saws, and fortunately some are able to run on each other's track system, which is handy. These saws are great for lace-in repairs, installing flush-mount wood vents, cutting the field for installing borders, cutting stair treads, and more!

How to be safe with a track saw

If you haven't used this type of saw before, one thing to watch for is kickback. To prevent this, you want to make sure you keep the saw stationary while plunging, i.e., don't move the saw forward and down at the same time or it will get jammed and come flying back at the operator.

One company even makes a track saw where the track stays attached to the saw! This is great for wide-plank installations.

Photo courtesy of Mike Reissig

Photo courtesy of Mike Reissig

5) Jig saw and reciprocating saw

Last on my list of essential saws are two saws that run neck-and-neck, the jig saw and the reciprocating saw.

The jig saw is super handy for curved cuts or finishing out incomplete cuts from the miter or table saw. You can get multiple styles of blades for these, and some are brand-specific depending on the saw you have. They typically come in a pistol-grip or barrel-grip style, and are also a great tool to add to your collection of cordless tools.

The reciprocating saw is great for any demo work or cutting stubborn nail-embedded wood. Before everyone had an oscillating saw, we even cut door jambs with the reciprocating saw using a long fine-toothed blade!

RELATED: First Aid on the Wood Flooring Job Site