Grill Works’ Top Questions About Wood Vents

Madison Baker, Inside Sales and Marketing

We know vents can often be an afterthought, and that’s usually okay. You don’t need to be an expert on wood vents—any reputable distributor or vent supplier should be able to help. That said, a little bit of knowledge about vents can help a distributor or retailer make an easy upsell and help an installer ensure the customer is completely satisfied.

At Grill Works, we’ve been making vents in Minnesota since 1986. Our sales and customer service team has over 35 years of experience in wood vents. This article is everything we wish our customers, and their customers (and their customers) knew.

What are the most popular styles of vents? Is there anything new on the market?

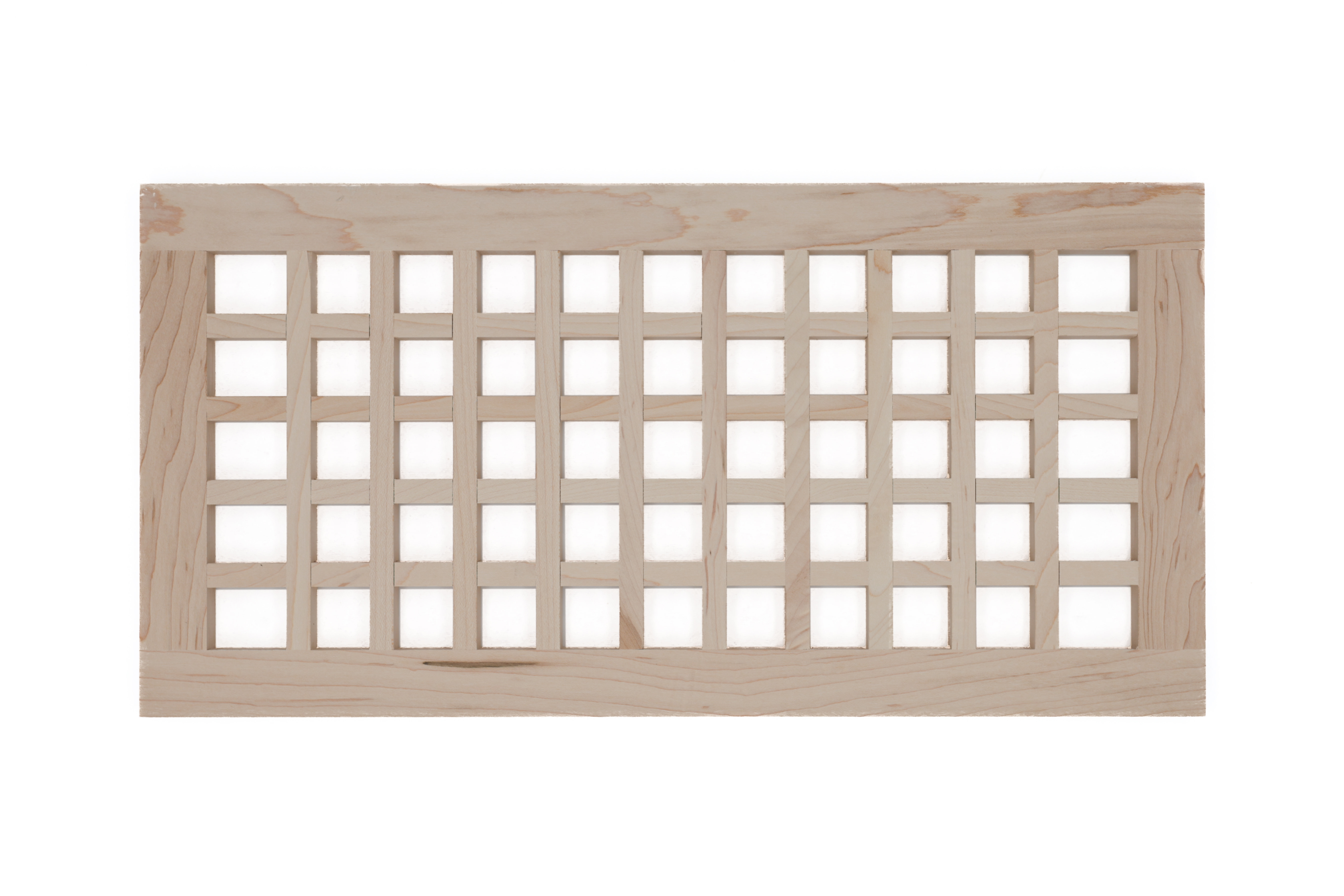

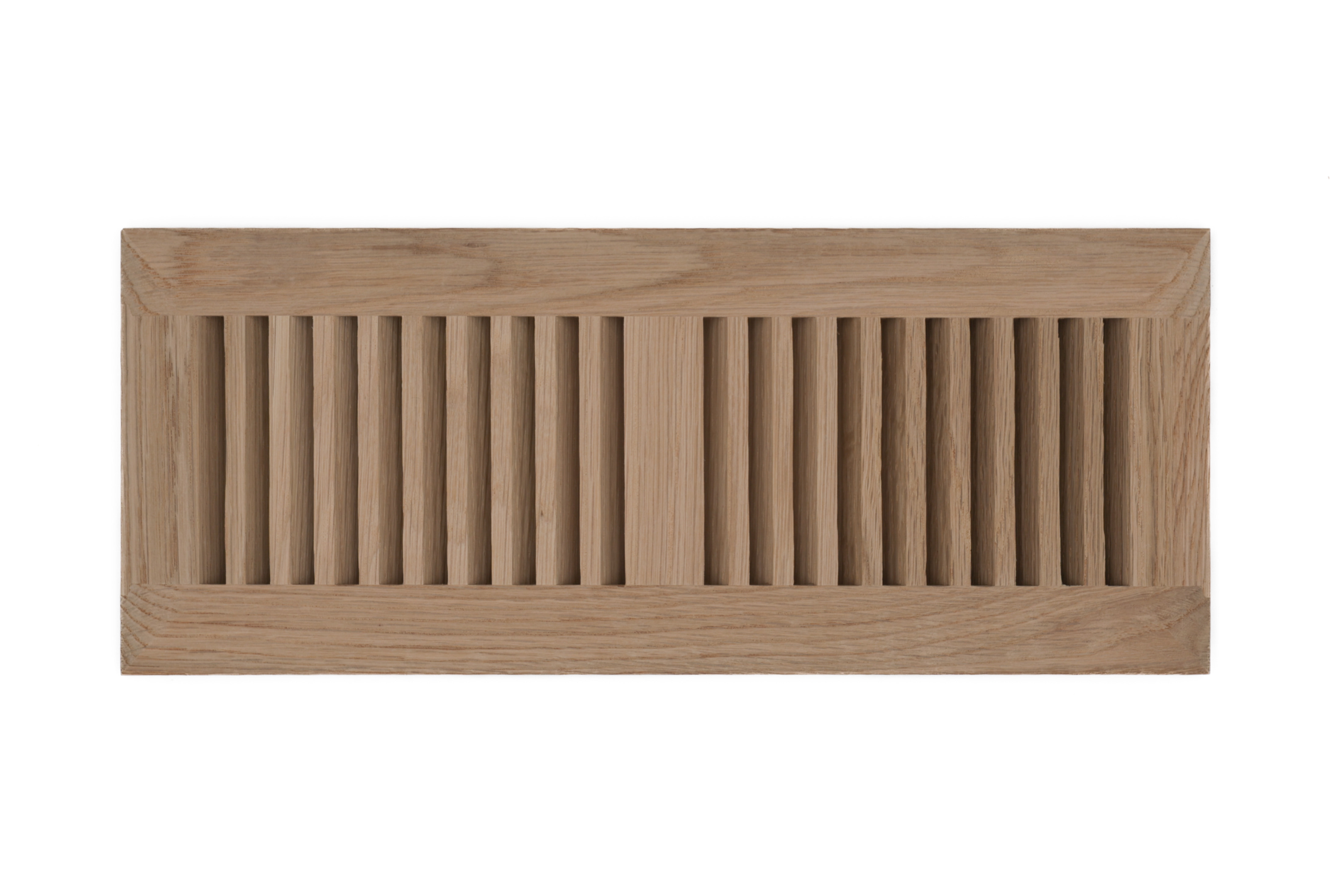

By far, the most popular vents on the market today are bi-directional louvered vents. These vents are clean, functional, and simple. We estimate that these vents make up 80–90% of all wood vents installed in homes today. Among other popular designs are eggcrate vents, which feature a classic grid pattern that provides high airflow and blends well with traditional-style interiors. Eggcrates are especially popular in the Northeast and work well for larger vents such as cold air returns.

Rising in popularity is the linear vent. These vents have straight louvers, perpendicular to the floor, complementing rooms with more modern designs.

Other, more unique options include offerings from brands like Fittes and Cradle. In these vents, the installer insets the flooring material into a cradle, ensuring an exact match between the vent and the flooring material.

Fading in popularity is the solid block vent. These vents are made of a single piece of wood with louvers cut out by a router. While easy to make and cheap to buy, these vents lack durability and do not provide good airflow.

Of course, there are also metal vents. Enough said on that.

What is the difference between a flush mount with a frame, a flush mount without a frame, and an insert vent?

Flush mount vents sit level—or flush—with the surrounding hardwood flooring, offering a sleek and clean look. These are the preferred vent for any new floor being installed. While they can be retrofitted, installation requires a professional and a bit of time and skill. Within this category, there are two subcategories: vents with a frame and without a frame. A flush mount with a frame includes a border that is installed on the subfloor, providing a fixed outline into which the vent fits snugly into a rabbeted inset.

The interior portion of the vent can easily be removed for duct cleaning or damper adjustment. In contrast, a flush mount with no frame integrates directly into the flooring itself without an added border. In some cases, a customer may prefer the minimalist look of a no-frame, flush mount vent. More than 95% of the flush mount vents are sold with a frame.

On the other hand, insert vents—sometimes called surface mount vents—are placed into a precut hole in the floor, with their rim resting on top of the hardwood floor. These vents are sometimes preferred when refinishing floors as a replacement for metal vents. The metal vent can be removed and the new insert vent installed without any modification to the duct opening or the hardwood around it. The main drawback, of course, is that the vent protrudes from the surface.

How can I maximize airflow without sacrificing aesthetics?

In an ideal world, an HVAC system is designed with wood vents in mind. Reputable vent companies publish airflow data that HVAC technicians can use to design a system that works well with the given specifications of wood vents. This can be an important part of the planning process, as wood vents can be more restrictive than other options. This can be overcome by adding more or larger duct openings. However, we understand that HVAC professionals are rarely consulting with flooring professionals, and that wood floor installers are not HVAC.

What should I look for in a high-quality vent?

While there is no shortage of vent choices on the market—between distributors, online retailers, local craftsmen, and Amazon—not all vents are of the same quality. If you are considering options, there are a few key areas to look at:

- Wood grade: Ideally, the vents you install are made of the same or better grade than the floor. Vents should be free of knots, especially in the louvers. Knots can decrease the strength of the vent, especially in areas that could be stressed such as the louvers.

- Squareness: A vent should be square; otherwise, you will see gaps after installation.

- Joints: High-quality vents have resilient joints that can withstand the stress a floor receives. Many vents have a dovetail joint with a metal fastener. Joints should not be loose, especially on the interior louvered portion of the vent.

- Louvers: Louvers should be straight and perpendicular to the floor. Lower-quality vents will often have slanted louvers or louvers with splinters. Splinters can increase the prep time required for an installer.

- Construction: It deserves mention again that quality vents are made of multiple pieces joined together with precision. This increases the strength of the vent. Low-quality, solid block vents lack durability because the grain in the louvers runs perpendicular to the louver itself.

How far ahead of time should I order my vents?

While vents and other accessories can be an afterthought, they shouldn’t be. The last thing any installer wants is to be waiting on vents, transitions, or some other piece required to close out a job. Most distributors typically stock unfinished vents in common species—red oak, white oak, hickory, and maple—in standard sizes (2x10, 2x12, 4x10, etc.).

If your job requires a special species or size, you should allow for additional time. At Grill Works, we always stock primary species of wood in all standard sizes. However, we make less common species to order. Between manufacturing and shipping, it can take 1-2 weeks for a distributor to get their hands on vents in specialty species.