Best in Show

Congratulations to 2002's Floor of The Year winners

Judges from the American Society of Interior Designers select the winners for all except Members' Choice awards, which are voted on by convention attendees. The Master Division is reserved for those who previously have won Floor of the Year awards; those who have not previously won awards are eligible for the Expert Division.

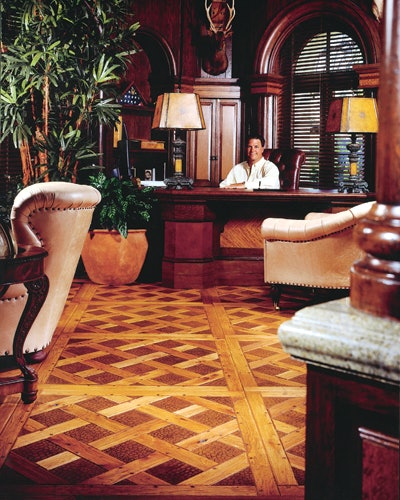

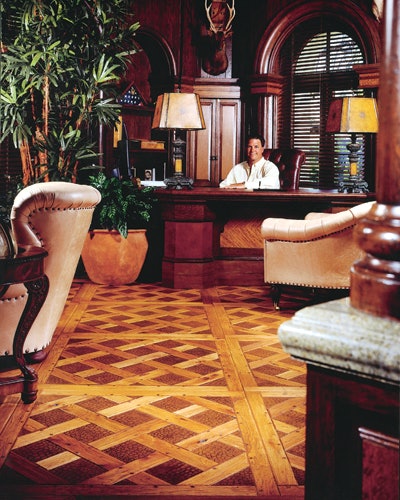

Return Performance Floor of the Year—Master Division | Birger Juell Ltd. (Chicago, Ill.)

This certainly isn't the first Floor of the Year award for industry legend Birger Juell, but this year's winning floor does represent several Floor of the Year firsts. It's the only time that different floors in the same house have won in back-to-back years. It's also the first time that a project with leather as part of the floor has been a winner.

The classic floor marks the completion of a two-year, halfmillion dollar project for the company. Last year, a foyer in the same 22,000-square-foot, Florida home earned Floor of the Year honors in the Master Division. This year, it's the same home's office that got the nod from ASID judges for the same award.

In typical Birger Juell style, every step of manufacturing the floor was a custom process at the company's 31,000-squarefoot facility. The large-scale parquet features stained character-grade hickory in a Versailles pattern with faux "alligator" leather centers. After being milled at the factory, each piece of flooring is handbeveled and hand-scraped by one of the 18 workers who do hand-scraping exclusively. Each one has been trained by Juell himself to scrape the wood following the grain in a fashion Juell likens to water flowing over rocks. Scraping the wood in this style yields production of 60 to 70 square feet of flooring a day per worker.

After scraping, the flooring is acid-stained with Juell's proprietary process and doubleoiled. For this floor, there was the additional step of manufacturing the leather inserts. To do this, workers cut hides to size and glue them to 5 / 8 -inch high-grade dimensional plywood for a full 3/4 -inch thickness. The plywood is tongue-and-grooved, as is the rest of the floor, and the leather is waxed with the recommended leather wax. The completed panels then are held together at the corners by hickory pegs. Together with the floor's mortise-and-tendon construction (a deeper tongue and groove), the pegs are all that holds the floor together until it is installed in adhesive on the job site.

Once installed, one of Juell's floors normally receives a final coat of oil and then wax. Because of the unique mixed media on this floor, the final process had to be done by hand, with care taken to not contaminate the leather inserts with the wood flooring wax.

The entire process may sound extraordinary to many contractors, but most things about Birger Juell are. At age 85, Juell's passion for his work is undiminished. He's still working nearly full time, and he was beaming proudly as ever when he climbed up on stage to personally collect his latest award.—K.M.W.

Suppliers Listed in boldface are advertisers in this issue.

Flooring: Birger Juell Ltd. | Finish: Dura Seal (oil), Birger Juell Ltd. (wax) | Adhesive: Bostik | Nailer: Stanley-Bostitch | Buffer: Clarke

Thinking Inside the BoxFloor of the Year —Expert Division | Best Limited Species Design | Old Country Hardwood Flooring (Calgary, Alberta)

Calgary, Alberta, may not seem the likeliest place to breed Floor of the Year winners. The area is a notorious prefinished wood flooring market that typically doesn't spend lots of money on high-end installations. But that's where David LaPorte, president/owner of Old Country Hardwood Flooring, has prospered. At this year's show, he garnered two trophies, winning Floor of the Year—Expert Division as well as Best Limited Species Design.

LaPorte's beginnings in the industry 13 years ago wouldn't necessarily lend themselves to Floor of the Year material. LaPorte found himself laid off from a job on a oil/natural gas rig when a friend suggested he buy a sanding machine. The friend just had purchased a 24-unit apartment complex full of wood floors in need of resanding. "He said he'd give me this whole building to do, and I did it. I've been in business ever since," LaPorte says. "I took all the training I could get my hands on along the way—schools, conventions, seminars and courses offered by our local suppliers. It's very important for us always to try to educate ourselves about products, techniques and equipment."

That's the attitude that has brought jobs such as this one to Old Country. The company worked closely with the homeowner and the project's designer, Connie Young, to develop the design. "We knew it was a natural fit for what they wanted to do, because everything in that place was just a series of boxes and squares and windows," LaPorte says. The final design includes a field of prime-grade Canadian hard maple strip set off by a series of black walnut 3/4 -inch feature strips, a layout LaPorte's company has dubbed its "Linear" pattern.

Once the layout was established, it wasn't a difficult installation, LaPorte says. The installers laid the entire field and sanded it once. They then installed all the feature strip in one direction and came back and routered through it in the opposite direction. The tricky part was finding the appropriate router to use where the feature strips meet flush up against the wall. In one area, the flooring and feature strip climb up a wall, where they are met by marble.

Once installation was complete, nonambering, commercial-grade waterbased finish was used to ensure the species' contrast would be maximized. The 2,600square-foot installation turned out to be exactly what the owner wanted. "The end result was that the customer was very satisfied. It just fit the place to a 'T,'" LaPorte says.—K.M.W.

Suppliers Listed in boldface are advertisers in this issue.

Installers: Ken Wallace, Blaire Handal | Sander/Finisher: Brad Martin | Flooring: Madawaska, Heartwood Architectural Wood Products | Finish: Basic Coatings | Sander: Lägler (Palo Duro) | Nailer: Stanley-Bostitch

Exotic Artistry Members' Choice—Expert Division | Crescent Hardwood Supply (Prairieville, La.)

It's not too often that a showroom design wins Floor of the Year honors in the Member's Choice—Expert Division, but Crescent Hardwood Supply's unique showroom is worthy of the coveted award. The modest 685-square-foot showroom features several borders, a medallion and 16 wood species, including mahogany, cumaru, tigerwood, ivorywood and Australian cypress.

It was the goal of John Troendle, president of Crescent Hardwood Supply, to feature as many species as he could on the floor of the Prairieville, La., branch, which opened last December. "Basically, we wanted a functional showroom as opposed to a beautiful showroom," he says. Most of the flooring contractors in his area don't have showrooms, so Troendle wanted to give them a place where they could bring their customers to see the different species first-hand and help them visualize their floors. Troendle also wanted to help introduce new woods into his market. "Not many people know about exotics, and we wanted to include more of the specialty items," he says.

Troendle enlisted the help of his installer-turnedsalesperson Marc Sholar to design and install the floor. The two sat down, combined their ideas and created the design in 3 1/2 hours. "We designed it so that if you stand in the center and make a complete circle, 90 percent of the species are facing you," Troendle says. The walkways and heavy traffic areas feature hardwoods from South America that are known for their durability. Species that don't have a border are picture-framed with 1 1/2 -inch maple strip. The outside pieces feature different grades of red and white oak.

In addition to his sales duties, Sholar worked on the showroom installation during his downtime until the floor was completed last February. Sholar welcomed the diversion from his sales duties. "I enjoy projects like that," he says, "I like a challenge." The installation basically went as planned, though one border was misplaced during the process and had to be moved to another section of the floor. Fortunately, the new placement of the border fit better with the design. "It was one of the few things we did even better than the original was supposed to be," Sholar says.

The reaction to the floor has been very positive from both customers and wood flooring professionals. Troendle says the floor has opened up new possibilities to homeowners who are used to single-specie, linear floors. The complex layout has given his customers the ability to think outside the box. "They can see that a floor can be one more piece of expression," he says. Sholar also has received accolades for his installation. He's even received several job offers from his wood flooring contractor customers, but he assures Troendle he's staying put.—C.L.

Suppliers Listed in boldface are advertisers in this issue.

Designers: John Troendle, Marc Sholar | Installer, Finisher: Marc Sholar | Distributor: Crescent Hardwood Supply | Flooring: Buchanan Hardwoods, Century Flooring, Historic Floors of Oshkosh, L&L Hardwoods, Rare Earth Hardwood, Robinson Lumber Company, Swift Lumber, Taylor Lumber, Zickgraf | Finish: Glitsa American | Nailer: Powernail Company | Adhesive: Bostik | Abrasive: Virginia Abrasives | Sander: Hummel (Palo Duro) | Buffer, Edger: Clarke | Saws: Makita

Modern GeometryBest Job-Site Finished Craftsmanship and Design | Integraf (Moscow, Russia)

Russia has a rich history that's reflected in its architecture, with stately historic buildings that house some of the most beautiful hardwood floors in the world. These ornate historic floors have served czars, kings and presidents for centuries. Russia's image, however, is changing. Modern, cutting-edge design now is becoming prevalent in a country known for its old-world beauty. Integraf, a Moscowbased custom parquet manufacturer established in 1994, is reflecting that change with its original, innovative flooring designs.

Integraf custom-designs its floors for every project, so each floor is unique. This 153-square-foot dining room floor was designed specifically for this Moscow apartment. The owners wanted a floor that would fit into the high-tech architecture and interior design style of the flat. Integraf's design team created several sketches for each room of the house. After several rounds of drawings, a geometric circle design was chosen. The clients were so happy with the final design of the floor, they exclaimed (in Russian), "This is what we need, the floor is perfection!" To prevent others from using this original design, Integraf agreed not to replicate this one-of-a-kind floor on another project.

To further add to the floor's unique character, Integraf used metal and exotic wood. Strips of American walnut form the large outer circles. The designers liked the natural pattern of the wood and thought the walnut gave the floor a sense of depth and diversity. To add contrast, a lighter wood, Austrian pear, forms smaller circles within the walnut field. The outer circles are separated by 3mm-wide aluminum flat bars.

Before installation began, the flooring was machine-cut at the factory. The aluminum arcs also were cut and shaped at the factory. Because each of the 12 circles has its own radius, mathematical precision was necessary to ensure that all the slats joined tightly together. The installers drew a detailed sketch on the subfloor to use as a guide. Each of the slats then was glued down following the template drawn on the subfloor. The aluminum arcs were screwed in place using predrilled holes at the base. The floor then was sanded, with special care taken to flatten out the areas where the metal and wood joined. Finally, the floor was finished—two layers of sealer were sprayed on, followed by five layers of waterbased finish.

The spectacular floors not only impressed the clients, but also the international hardwood floor community. The recognition Integraf once again received has turned cutting-edge hardwood floor design into one of Russia's best exports. —C.L.

Suppliers Listed in boldface are advertisers in this issue.

Designer: Tatiana Kotelnikova | Installer, Finisher, Flooring: Integraf | Finish: BonaKemi | Adhesive: Franklin International | Abrasive: 3M Co. | Sander, Buffer, Edger: Alto | Saws: Mafell

Russian CompositionBest Use of Wood Technology | Integraf (Moscow, Russia)

When Mikhail Gorbachev unveiled perestroika to the Soviet congress in the late '80s, it spawned massive economic, political and social reform. Western influence, along with a new wave of Russian self-expression, emerged from a once-stymied culture. The change is evident in every aspect of Russian life, from its architecture, interior design and even its wood flooring. While there still are many differences between Russia's culture and the West, this year's winner in the Best Use of Wood Technology category, Integraf, proves one thing: the artistry and craftsmanship of wood floors is a universal language.

This winning floor design is in a 132-square-foot music room of a Moscow apartment. Artists Valery Blinov and Tatiana Kotelnikova made several sketches for the client before deciding on this original design. The architect wanted the floor to be a combination of classic design and contemporary flair. The floor also needed to complement the furniture and the grand piano, which the client already had purchased for the flat.

Integraf, a company known for its high-end parquet design, chose quartersawn oak and Karelian birch for the main area of the floor, and American walnut, Austrian pear and Karelian birch for the outside border. The designers wanted a wood with a soft, natural-looking grain that would give the room a subdued tone and blend with the oak parquet throughout the rest of the flat. They also wanted to complement natural light emanating from large picture windows in the room.

In keeping with the musical, performance theme of the room, the floor is laid on a raised podium area just off the living room, lending a three-dimensional feel to the room. The music room is offset by a lighted footstep, also installed by Integraf. Adding dimension to the room are the radial pattern of the floor and contours in the border that accent the lines of the piano and the furniture. The details in the border were machine-cut at the factory and installed onsite.

The floor was finished by spraying on two coats of sealer and five coats of waterbased finish—a standard finishing technique for Integraf. The floor finally was completed, with the last coat of finish, in 90 days—and it was well worth the wait.—C.L.

Suppliers Listed in boldface are advertisers in this issue.

Designers: Valery Blinov, Tatiana Kotelnikova | Installer, Finisher, Flooring: Integraf | Finish: BonaKemi | Adhesive: Franklin International | Abrasive: 3M Co. | Sander, Buffer: Alto | Saws: Mafell

Roll With the ChangesBest Manufacturer-Finished Design | DM Hardwood Designs (Mission Viejo, Calif.)

One thing most contractors are skilled at is rolling with the changes. With construction, it's a given that projects won't go according to the plan or schedule. This year's award winner from Mission Viejo, Calif.-based DM Hardwood Designs definitely fits into that category. The focus of the floor, a large medallion, was custom-designed for a circular entryway in a home being built for high-end clients. The bid was completed, the contract signed and the wood ordered. At the last minute, the couple suddenly bought an entirely different house.

"I said 'well, where are we going to put this Floor of the Year-type floor that you bought.' " Dave Marzalek recalls. "'We've now gone from a circle to a square.' " They all determined that the only appropriate place in the house was the entryway, Marzalek modified the layout appropriately and the medallion was cut. Unlike all of Marzalek's previous winning medallions, this one was laser-cut using a CNC machine from a factory owned by the client. Marzalek assembled the pieces, making adjustments and cutting new pieces along the way.

Once the medallion was completed, the client didn't like it. She decided that the scrollwork detail forming an outer ring was too much and too big, so that part of the medallion was scrapped. Next, she deemed the colors of some of the species to be too purple or red. So, Marzalek built a new medallion, which she loved.

"Everything on this project was about changing and redoing," Marzalek says. "As the floor was being done, they were tearing down a wall right next to it." Once the medallion was done, the rest of the project moved relatively quickly. With the help of friend Brett Elliott, Marzalek installed prefinished distressed maple planks in a quadrant pattern along with a border that matches the medallion's own outer rim.

When the finished floor and two others were professionally photographed for Marzalek's portfolio and Web site, he didn't think this one was a Floor of the Year winner. But his wife, Shannon, and son Darren picked it as a winner. "Darren said, 'That's your trophy,'" Marzalek says. Darren proved to be wiser than his nine years, as he got to accompany his dad on stage to collect DM Hardwood Design's trophy No. 11. — K.M.W.

Suppliers Listed in boldface are advertisers in this issue.

Distributor: Galleher Hardwood Co. | Flooring: Rare Earth Hardwoods, Goodwin Heart Pine, Galleher Hardwood Co./Harris-Tarkett | Finish: Berger-Seidle (on inlay) | Adhesive: Bostik | Nailer: Erico, Senco | Abrasive: 3M Co. | Buffer: Alto U.S. | Saws: Hegner, Hitachi, Makita

Contemporary ClassicBest Manufacturer-Finished Design—Honorable Mention | OY Karelia Parketti Ltd. (Kuopio, Finland)

It used to be that Finland was synonymous with cold weather and saunas, but innovative, quality exports such as Nokia phones, fine ceramics and chic furniture have turned the country into a Mecca of European design. Oy Karelia Ltd. is bringing that innovative Finnish design to the world of wood flooring.

This winning design is a 500-square foot foyer in a two-level upscale residence located in the outskirts of Pirkkala, the capital of Finland. The project was a complete renovation of a historic building from the early 1900s. The design concept was to blend the old features with a new, modern design. The owner also wanted to use high-quality, durable materials while still reflecting a sense of individuality. Approximately 2,700 square feet of flooring needed to be replaced, and the architect chose to use Karelia's Two Strip Jatoba downstairs and Birch Saima throughout the entire ground level.

The Saima flooring line used on the project has been in existence for years and originally was the brainchild of Professor Alvar Aalto, who came up with the design in the '50s. The product was manufactured and sold by another company until Oy Karelia acquired the firm in 2001 and redesigned the Saima line to be competitive with other engineered products on the market while still maintaining its unique design.

The company launched its version of the Saima line last year, and the architect of this project was one of the first to install the improved product. This engineered floating floor was chosen not only for its durability, dimensional stability and ease of installation (it took only three days to install all 2,700 feet of flooring), but to complement the modern architecture and clean lines of the project while maintaining a soft, natural tone.

The floor's Northern Birch wear layer lends itself to the light, open-air feel of the structure. "Birch is considered to be Finland's national tree, so it synchronizes with nature outside," says David Nemes of Oy Karelia. The planks also have the unique characteristic of reflecting light in different ways depending on the direction they are installed, giving the illusion of different species. This floor was installed in a Dutch Design configuration featuring 5.9by-11.8-inch planks running perpendicular to the field. These perpendicular planks appear lighter and give the floor a subtle square pattern.

While the floor may have a light, unassuming tone, its durability makes it a practical floor as well. With six coats of UV-cured Acrylate matte finish, this product is also able to withstand the high traffic of a foyer—another example of Finnish ability to combine unique form with function.—C.L.

Suppliers Listed in boldface are advertisers in this issue.

Installer: Parkettiasennus Reijo Korhonen | Flooring: Oy Karelia Ltd.

A Familiar SightBest Design in a Commercial Application | SCS Hardwood Floors (Orlando, Fla.)

When the winner of the Best Design in a Commercial Application category flashed up on the screens during the NWFA convention in Orlando, the wood floor was familiar to many present at the luncheon. Coincidentally, it was the wood floor in Auggie's, the very piano bar that was the main evening hangout for convention-goers at the show's host resort, the Gaylord Palms.

SCS began pursuing the job long before the Gaylord became reality. "When the Gaylord Palms was put out to bid, we just started putting the word out that we wanted to do any of the wood that would go in there," says Darrell Rogers, vice president of SCS Hardwood Floors. With 20 wood flooring crews and 30 years of experience, SCS is ready to tackle nearly any type of wood flooring job that comes along. "Because we're one of the largest dealers in central Florida, a lot of the bigger jobs come our way right off the bat," Rogers says. The company's business runs the gamut of the industry, averaging about one-third commercial, one-third retail, and one-third residential work.

On this commercial project, SCS made sure its own bids were included in the bids of several contractors going after the project, guaranteeing SCS the flooring work. In the end, the project included several suites, but the showpiece was the piano bar, which features more than 3,000 square feet of acrylic-impregnated maple glued down in a unique pattern. As is typical on such large commercial projects, the design was dictated by the corporation's design team. That's business as usual for SCS, which is used to doing work for huge corporate entities such as Disney and Universal Studios. "Sometimes they spend more than what the floor costs just to design these things and get the color schemes," Rogers says. "It's amazing some of the money that gets spent."

On-site obstacles for installer Jack Rogers, Darrell's brother, included having to raise the subfloor 2 1/4 inches to get it flat and figuring out the layout so the pattern appeared consistent around the bar. One of the most time-consuming aspects was installing the floor by each separate raised booth area around the perimeter of the room—booths that were later torn out.

Although the SCS crew was "definitely thrilled" to earn the award, it's just one part of the company's plan for success— one focused around customer service, continual education and aggressive marketing that includes radio and television commercials. Darrell and Jack even have a slot as the wood floor experts on an Orlando radio home show every Saturday. It's a business they take very seriously. "We don't want to give anybody a chance to catch up or take away what our parents have worked hard for and what we've tried to keep," Darrell Rogers says. If winning their first Floor of the Year award is any indication, the SCS crew is achieving that goal. — K.M.W.

Suppliers Listed in boldface are advertisers in this issue.

Flooring: PermaGrain Products

Functional BeautyBest Showroom Design | Schumacher & Company (Newport, Ky.)

The purpose of a hardwood flooring showroom is to display the craftsmanship of the company and allow customers to envision the possibilities. Most showrooms feature a little bit of everything and have myriad species and flooring samples laid into the floor. Instead, this year's winner, Ken Schumacher, owner of Schumacher & Company, chose a simple, elegant design for his 256-square-foot showroom in Newport, Ky. Schumacher wanted to make the best use of the 16-by-16 foot showroom, while still showcasing the high-end work his company is capable of achieving.

This branch showroom is part of an upscale architect's large design center. Several trades are located under one roof, which makes it easy for his clients to make design selections. Targeting the high-end consumer, Schumacher wanted to keep the design of the showroom simple, while showing as many species and options as possible. Schumacher chose to limit the installed floor to maple, oak and American cherry and to include a border with wenge, American walnut and Brazilian cherry. "This looks like a floor that you could put in any room of your house or business," Schumacher says. "It's not hodgepodge, or a bunch of different floors." He also chose to use quartersawn lumber, not only for its superior quality, but for its limited expansion in a glue-down-over-concrete project such as this one.

Schumacher designed the layout using AutoCAD software. He finds this is convenient—because many architects' plans already are in AutoCAD, and he can plug his floor design right into their layout. Planning the floor was a mathematical challenge, since everything was done in multiples of 4 inches. "Everything hits on a point," he says, "And to make the octagon do that was kind of tricky." The border around the octagon consists of a 1/2 -inch border inside a 4-inch cherry and walnut border. The main field of the floor features a maple and cherry "Marie Antoinette" pattern similar to a basketweave. Schumacher took regular plank flooring and precut all of the pieces either 8 inches or 20 inches long. The maple blocks in the middle of the pattern consist of two 4-by-8-inch pieces glued together to look like 8-inch squares. Twenty-inch cherry strips frame the maple squares.

To display the many colors and styles of flooring available, Schumacher has large, custom-built birch and poplar racks that house 80 18-by-18-inch samples and 10 larger parquet samples. These "selfserve" custom racks allow customers to choose samples they like and call the main office to get specific pricing information. Prospective buyers appreciate both the nopressure environment and the classy, high-end atmosphere.—C.L.

Suppliers Listed in boldface are advertisers in this issue.

Designer: Ken Schumacher Installer, | Finisher: Schumacher & Co. | Distributors: Lanham Hardwood | Flooring: Historic Floors of Oshkosh, Fine Lines, Taylor Lumber Co. | Finish: Basic Coatings | Adhesive: Franklin International | Abrasive: 3M Co. | Sander: Hummel (Palo Duro) | Buffer, Edger: Clarke Saws: Dewalt

An Upward Journey Best Member's Residence Design | Craftsman Flooring & Finish (Saugus, Calif.)

In a way, Marc McCalla of Craftsman Floor & Finish in Saugus, Calif., has been climbing the floor covering ladder for the last 20 years. Starting in carpeting and then moving to vinyl, McCalla's been concentrating on hardwood for the last 10 years. Now, he's focusing on always taking his wood flooring business to the next level of custom work and unsurpassed customer service.

To achieve that, McCalla has sought guidance at NWFA schools, including the NWFA Advanced School. He credits Advanced School instructors such as Tom Peotter and Chuck Crispin for hammering home principles that define upper-echelon work, such as meticulous attention to detail. He also points to his friend, colleague and mentor Steve Marley, whom he met during an inspection, as the standard of professionalism and quality work to which he aspires.

Using his education, McCalla has built a business that prides itself on "doing the small things other contractors don't want to do," McCalla says. "We make sure the customer's home is well protected and do things we feel really bring integrity back into the trade." He's also always looking for an opportunity to put his Advanced School skills to work. About 50 percent of his current business is hand-distressing, but opportunities for detailed border and inlay work haven't been too frequent.

For this foyer and dining room installation, however, McCalla had free rein to use his intricate custom design skills. Species were selected to mirror the maple, walnut and cherry furniture in the dining room. The custom design uses bands of walnut, Brazilian cherry and black walnut to form a cross, achieving balance and symmetry in the rectangular room. A similar design is flip-flopped in the entryway. A good part of the work involved figuring out the layout, McCalla says. Then, much of the material was milled on site, using jigs to cut pieces for the repeating patterns.

It actually was the entryway that McCalla thought had a better chance of winning Floor of the Year, but he's just as pleased the judges deemed the dining room worthy. With his unrelenting desire to improve, he's hoping the company's first Floor of the Year award is an impetus to "take the company to the next level."— K.M.W.

Suppliers Listed in boldface are advertisers in this issue.

Distributor: Galleher Hardwood Co. | Finish: BonaKemi USA | Nailer: Stanley-Bostitch | Adhesive: Bostik | Abrasive: 3M Co. | Sander, Buffer: ProSand (BonaKemi USA) | Edger: Viking | Saws: Hitachi

Take a look at past Wood Floor of the Year winners:

Sweet Victory: 2001 Floor of the Year Winners