With a revamped and expanded NWFA Floor of the Year contest, there were five new faces on this year's winners' podium, along with a couple of previous winners.

There were nine awards presented in this year's Floor of the Year Contest. Attendees at the 1997 NWFA Convention in Nashville, Tenn., chose two winners — those for the Members' Choice Awards presented in the Master and Expert Divisions. (The Master Division was reserved for companies that had previously won Floor of the Year honors, while the Expert Division included companies that had not previously won.) The other award winners — including Best of Show in the Master and Expert Divisions— were chosen by representatives of the American Society of Interior Designers. As it turns out, there were two double winners, since the Members' Choice winners were also honored by the ASID judges.

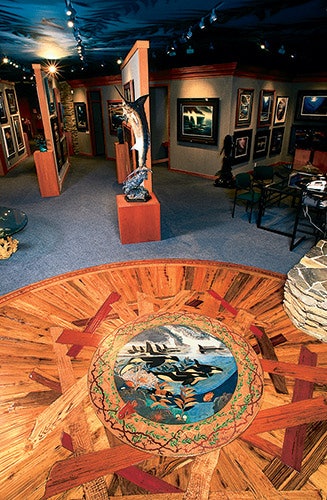

Wood mixes with water for Marzalek's aquatic scene. - Click to enlarge

Wood mixes with water for Marzalek's aquatic scene. - Click to enlarge

Continuing Journey

DM Hardwood Designs, Mission Viejo, Calif.

Members' Choice — Master Division, Best Design in a Commercial Application

"It's a hobby that's gone out of control." That's how Dave Marzalek describes the work that has now garnered him back-to-back Members' Choice awards in the Floor of the Year contest.

While last year the little-known contractor seemingly came out of nowhere with his elaborate Native American design, this year few were surprised to see Marzalek's "hobby" win again, this time with the "Orca Journey" inlay, which won the awards for Members' Choice in the newly created Master Division and Best Design in a Commercial Application.

This year's project began as a request from Marzalek's wife, Sharon. They had sold their house and last year's winning inlay, and "she wasn't going to let me put that Indian design in our next home," Marzalek explains. When the couple were shopping on San Francisco's Pier 39, Sharon saw what she wanted for their next floor at the Wyland Art Studio & Gallery: the oil painting of Orca Journey, the famous artist's most published work. Through the gallery, Marzalek offered to make an inlay for Wyland if he could make one for his wife. After talking to the general contractor building Wyland's new gallery in Laguna Beach, Marzalek was not only making the inlay to go into the new gallery, but also installing 3,000 feet of ash in the building.

Given a template of the painting to go on, Marzalek began constructing the inlay as he always does: working for a few hours a night while he watches baseball in his garage. About 200 hours were spent on the inlay alone, which was completely prefinished before being installed at the job site. The pieces were hand-sanded and painstakingly finished, with various combinations of dyes, lacquers and clear coats. On top of everything, some areas — such as the water and misty white clouds — have a pearl effect added to their finish, enhancing the illusion of water.

When it was time to go to the job site, Marzalek and his brother, Sean Marzalek, and Jim Shultz graphed out the area for the inlay and went about installing and finishing the surrounding floors. They distressed the boards that surround the inlay — using everything from a welding torch to chains to a coat hanger on the floor. Ten species were used to create the seemingly broken boards. When all was completed, the inlay was dropped in, and the floors surrounding it hand-scraped.

It was especially rewarding for the final work to be recognized by Wyland himself. "The floor gets a lot of attention in the gallery," says Marzalek. "I don't think he expected what he got." It's probably safe to assume, however, that NWFA members will have great expectations for Marzalek's entries in future Floor of the Year contests.

SUPPLIERS LISTED IN BOLDFACE ARE ADVERTISERS IN THIS ISSUE

Distributor: Galleher Hardwood | Abrasives: 3M Co. | Adhesive: Bostik Inc. | Composite Flooring: Phoenix Biocomposites | Buffer: Clarke Industries | Flooring: Rare Earth Hardwoods (¼-inch tiger maple, exotic woods), Sandy Pond Hardwoods (¾-inch tiger maple), Goodwin Heartpine (heart pine) | Finish: Basic Coatings | Hand Scrapers: DM Hardwood Mfg. | Jigsaw, Jointer, Planer, Router, Table Saw, Slide Saw: Hitachi | Nailer, Saw Blades: Senco

Dorffler got his creative wish with this maple floor. (©1996 Scot Dorffler) - Click to enlarge

Dorffler got his creative wish with this maple floor. (©1996 Scot Dorffler) - Click to enlarge

Unlimited Imagination

Scot Dorffler Hardwood Flooring, Sacramento, Calif.

Members' Choice — Expert Division, Best Limited Species Design

The first three drawings Scot Dorffler presented to the owners of this house didn't have much of an effect. "I wasn't thrilled with the drawings and they weren't either," says Dorffler. "They were pretty basic things — a frame, a border." Then he pulled out a fourth drawing and explained that that was what he really wanted to do.

As it turns out, the fourth drawing was a charm. "They like artistic, whimsical decor," says Dorffler of the home owners, "and that extended to the floors. They supported my ideas and gave me artistic license." The result was a floor Dorffler now calls a "once-in-a-lifetime opportunity."

The owners didn't rush. To renovate their home, they moved out for nearly a year and their house was practically gutted. Dorffler, who is his own one-man shop, spent more than six months on the floors throughout the home, which included 2,500 square feet of maple. He had been working on the floors for four months before the design for the entryway was finalized — right before the owners left for a two-month trip to the Antarctic.

Dorffler used a combination of white, bird's-eye and quilted maple. All the white maple was laid at a 45 degree angle, converging at the entryway at four different angles. Dorffler manipulated the natural shades of the wood and used aniline dyes and faux-finishing to achieve the desired three-dimensional effect.

All wood used was ¾-inch — no veneers or 5/16 flooring was installed. "I really wanted to do something that was going to last," says Dorffler. Everything interlocks with a tongue and groove, even where slip tongues had to be used. Five coats of oil-based finish protect the floor, but as it turns out, Dorffler's "labor of love" doesn't need much protection. "The owners treat it like a piece of artwork. They don't let anybody on it with shoes," he says.

SUPPLIERS LISTED IN BOLDFACE ARE ADVERTISERS IN THIS ISSUE

Abrasive: 3M Co. | Adhesive: West System Epoxy | Buffer: Squar-Buff, Unico | Edgers: Clarke Industries, Lägler (Palo Duro) | Flooring: Green River Lumber, Rare Earth Hardwoods, Sandy Pond Hardwoods | Finish: Glitsa American, Guardsman Stains | Nailer: Stanley-Bostitch, Senco | Sander: Clarke Industries | Saws: Colladay, Delta, Hitachi, Makita, Unisaw

Hand-cut inlays and Italian marble combine in this renovation. - Click to enlarge

Hand-cut inlays and Italian marble combine in this renovation. - Click to enlarge

Elite Repeat

Renaissance Floor In-Lays, San Francisco, Calif.

Best of Show — Master Division

Being the winningest company in Floor of the Year history doesn't diminish the honor. "I've been on that stage eight times already, and it's the thrill of a lifetime every time they call your company name," says Eugene Klotz, partner in Renaissance Floor In-Lays. This year Klotz ascended the stage to accept the Best of Show — Master Division award for this elaborate mixed media installation.

This year's winning entry, a residential renovation, marks the first time Renaissance tried a mixed media project. Klotz shares the design credit with the home's owner, an expert in stone. "He purchased his house on a beautiful estate, but it was lacking some touch," Klotz says. The duo collaborated as the home owner went about collecting hundreds of brochures and samples of different marbles from around the world.

As the tiles and rosette were selected, Klotz studied the stones to create the surrounding floor patterns, many of which are variations of patterns already in Renaissance's inlay catalog. The patterns, including the pickets, were adjusted to the size of the tiles. After the subfloor was prepared for a large square marble piece in the entry, the Italian marble rosette arrived and turned out to be circular — requiring some quick design adjustments.

With the designs approved, Renaissance's Tommy Krynski cut most of the circular ornaments, while Klotz's 18-year-old son, Charlie, learned to cut the straight ornaments. Sapele, santos mahogany, avodiré and wenge were all used in the inlay, while the skirt is formed of quartersawn domestic cherry. Because of the 18-inch-square marble tiles, special care had to be taken to level the subfloor. The floors were then finished with four coats of oil-based polyurethane. To prevent moisture problems from the yet-to-be-installed marble, the wood was finished on all sides, not just on the top.

The entryway floors aren't the only area in the home graced with Klotz's handiwork — the ceiling of the library has 24 panels with inlaid rosettes and its floor has a mix of marquetry and marble, as well. Klotz expects to extend his remodeling work in the home in the near future.

While the coming renovations perhaps would again be Floor-of-the-Year quality, don't expect to see them in next year's contest. "I get a feeling that it's probably time to step aside for a few years and watch it," says Klotz, who was happy to see this year's contest expanded and so successful. Don't count Klotz out long-term, however. "Perhaps in a couple years, I will have one or two floors to enter," he says. And it's probably a safe bet that Klotz's sabbatical won't harm his Floor of the Year winning touch.

SUPPLIERS LISTED IN BOLDFACE ARE ADVERTISERS IN THIS ISSUE

Installers, Finishers: Jarek Bienkowski, Manuel Castillo | Distributor: Golden State Flooring | Abrasive: 3M Co. | Adhesive: Bostik Inc. | Finish: Dura Seal | Flooring: Firebird Industries | Marble: Ancient Venetian Flooring Co. | Nailers: Stanley-Bostitch, Senco | Sander, Edger: Lägler (Palo Duro) | Buffer: Clarke Industries | Saws: Makita, Hitachi, Powermatic

Every piece of wood in this installation was hand-cut. (©1997 Judy Alfter) - Click to enlarge

Every piece of wood in this installation was hand-cut. (©1997 Judy Alfter) - Click to enlarge

Leap of Faith

Michael D'Angelo Inc., Marina Del Rey, Calif.

Best of Show — Expert Division

The most difficult part of this floor was convincing his men that they could do it, says Michael D'Angelo. "I have a tendency to frighten them when I design things," he explains. "They say, 'We can't do this,' and I say, 'Oh yes, we can.'" D'Angelo's persuasion on this particular job did wonders, garnering the Floor of the Year rookie the Best of Show award in the Expert Division.

With a background in design and 25 years in the hardwood floor business, D'Angelo specializes in creating wood floors to fit their architectural spaces. This floor presented itself when the home owner, a high-profile fashion designer in New York and Hong Kong, came to D'Angelo looking for something unique for his new home. The owner originally considered marble for the entryway, but didn't want anything geometric. D'Angelo took the floor plans and began looking through reference manuals, Architectural Digest — anything for inspiration. When he presented his drawings, "the owner just fell in love with it."

The entire installation isn't visible in one photo — it encompasses the 700-square-foot entry, two smaller circular rooms on either side, and a curved bridge, all of which are custom inlays. For the Floor of the Year winning portion, rift-sawn white oak was chosen for the central oval, with African wenge selected for the border. The staircase is American black walnut.

Before any wood was cut, however, large plywood templates were created and taken back to the shop, where six months were dedicated to sizing and cutting the boards. Every board in both the swirling oval area and the chevron-shaped border had to be individually shaped and mitered to fit into the floor. Once on site, installation began in the center, where each piece had to be routed so that the board would meet in an exact point, now covered by the ballerina sculpture in the middle of the room. About a month and a half was required to glue down and finish the floor with a water-based finish.

"A lot of people at a quick glance don't realize the time and effort put into something like this," says D'Angelo. Luckily for him, the ASID judges were perceptive enough to reward his — and his men's — time and effort.

SUPPLIERS LISTED IN BOLDFACE ARE ADVERTISERS IN THIS ISSUE

Installer: Frank Silva | Finishers: Miguel Santibanez, Alfredo Ramirez | Distributor: Michael D'Angelo Inc. | Adhesive: Bostik Inc. | Abrasive: 3M Co. | Finish: Skanvahr Coatings Inc. | Sander, Buffer: Lägler (Palo Duro) | Saws: Kirshfield

Flowered vines naturally criss-cross in this maple floor. - Click to enlarge

Flowered vines naturally criss-cross in this maple floor. - Click to enlarge

The Great Indoors

Endurance Floor Co. Inc., Miami, Fla.

Unfinished Craftsmanship and Design

The first day Leonard Hall worked on this floor, he said a prayer. "I said, 'Please don't let me mess up now,'" he recalls. "It's one of those jobs where you can't undo anything because everything's so interwoven and interlocked."

His prayers were answered. Not only is the floor flawless, it impressed the ASID judges enough to garner this year's award for Unfinished Craftsmanship and Design. The floor features 140 feet of vines and flowers inlaid into a field of 3¼-inch, first-grade maple that covers the home's foyer, gallery, living room and dining room.

The idea grew from the home's designer, Dalia Berlin, who had seen laser inlays with similar natural motifs but didn't like the repetition. Hall came up with a sample template for a custom design, and Berlin gave him the job, carte blanche. "I told my partner, Martha Smith, 'This is going to take awhile; you're going to have to cover for me,'" he says. He was right: Hall delved into research on botany drawings, the beginning of a project that would end up taking 318 hours to complete.

Once the maple was installed, it was rough sanded at the perimeter, allowing Hall to sketch the vines on flat, clean wood. Drawing the freehand sketch of the vines and flowers took 5½ days, while at the shop, the raw poplar lumber for the vines was being resawn and planed into ¼-inch-thick blanks. With the floor sketch complete, it was traced with tracing paper and copied onto the poplar with carbon paper. Once those were cut, the floor pattern was retraced using the cut poplar pieces and the maple was routed out.

To create the curving flower stems, Hall used a ⅛-inch bit on the router to cut out a path ⅛- to ¼-inch wide. He then used ⅜-inch poplar blanks that had been soaked in water overnight, taking on a consistency similar to cooked spaghetti, and shaved them with a small hand plane and utility knife to fit in the slot's variable width. Yellow wood glue holds the stems in place.

Hall included 142 flowers and buds in the piece, no two of which are exactly alike. Bubinga, cocobolo, Indian rosewood, lacewood, American cherry, mahogany, Brazilian cherry, padauk and bird's-eye maple were all used for the flowers. Careful attention was paid to positioning the flowers in realistic positions relative to the sunlight in the house. In front of sliding glass doors, it appears that the wind has blown the flowers, leaving several petals and leaves scattered on the floor. Hiding inconspicuously in other areas of the floor are three ladybugs of padauk and wenge and two butterflies of ash and purpleheart.

Such attention to detail resulted in a floor that both Hall and the owner consider to be more a work of art than a floor. In fact, the owner requested that Hall sign the floor with his signature, which he did on top of a vine using a very fine router bit. It was a fitting end for Hall's first freehand inlay project and more than three months of painstaking work — a project Hall says comes along only once in a lifetime.

SUPPLIERS LISTED IN BOLDFACE ARE ADVERTISERS IN THIS ISSUE

Distributors: Custom Wholesale, Miami Hardwoods | Abrasive: Norton Abrasives | Adhesive: Elmer's | Buffer, Sander: Clarke Industries | Flooring: Tembec | Finish: BonaKemi USA, Ultradec | Nailer: Powernail | Saws: AMT, Dremel, Ryobi, Sears

Prefinished cherry floors make a 'breathtaking' statement in this hospital installation. - Click to enlarge

Prefinished cherry floors make a 'breathtaking' statement in this hospital installation. - Click to enlarge

Precisely Done

Master Care Flooring Inc., Columbia, Md.

Prefinished Design

Although about 40 percent of Master Care's business is with prefinished flooring, the company had never done a prefinished job as labor-intensive as this floor at Johns Hopkins Hospital. A crew of four men spent three weeks installing it, making a total of 23,000 cuts in the process, and focusing on precision. "We were splitting hairs with the whole job trying to get it to work right," says Russ Sterner, Master Care's vice president. "There was zero room for error."

The zero tolerance for error stemmed from the specified geometric design, which called for the prefinished PermaGrain cherry floors in a square pattern with 6-inch black granite centers. The squares had to measure exactly 72 inches across, with no filler to rely on for minor corrections. "With wood, even PermaGrain, nothing can be exact," says Sterner. One square would be 1⁄32 of an inch off, requiring a lot of adjustments with a rubber mallet to make things work.

The actual layout was challenging, as well. Designer Peg Walsh of Swan Hall had determined the desired sizes of the squares with the marble centers, and wanted them to line up centered between four doorways, a long hallway and two main doors. "We really had to play with it to get full-size squares," says Sterner. "We spent two days on the job on layout alone."

The installers first tried building the square panels on site, but when that didn't work, they went back to the shop and prefabbed them there. To keep the floor as flat as possible, all mitered joints were splined.

When enough panels were glued down, the assembly process was moved back out to the hospital, and the rest of the square panels were dropped into place.

In the end, the floor turned out better than they had ever imagined. "When we first looked at the plans, we though it was too busy," remembers Sterner. "But when it was done, it really fit the area." Although Master Care didn't recommend it, hospital maintenance people wax the floor once a week, and "it looks like a million dollars," says Sterner. "It's breathtaking; it's so pretty." Obviously the Floor of the Year judges agreed, awarding yet another first-time entrant a Floor of the Year trophy.

Installer: Pat Joy | Distributor: Rosell-Heck | Adhesive, Flooring: PermaGrain Products | Saw: Hitachi

Precision was paramount in this geometric floor. (©1997 James Prince) - Click to enlarge

Precision was paramount in this geometric floor. (©1997 James Prince) - Click to enlarge

Natural Reflection

Design Hardwoods By Royal K Flooring, Aberdeen, N.J.

Best Use of Wood Technology

Part of a $3 million residential expansion, the floors in this room were carefully laid out to reflect the architectural patterns and skylights in the ceiling. The designers came to high-end flooring contractor Royal K with their desired layout in mind, but looking for recommendations on species.

Dimensional stability was the foremost concern in selecting the wood to be installed: Not only is the home located on the water, this particular room is a transition between the kitchen and an indoor swimming pool. Quartersawn red oak, purpleheart, santos mahogany, bird's-eye maple and northern white maple were chosen.

Original plans from the designers called for the border pattern to surround a large area rug. "We said that was a mistake and they should go with more of a subtle, custom-made pattern," says Julian Kroll, Royal K's director of sales. The result was the custom parquet pattern in quartered red oak.

"The most challenging part was utilizing the geometry in the room," explains Kroll — "getting the diamonds to hit up against the windows and the striations on the ceiling to match up on the floor." The floor's layout had to be accurate within ⅛ of an inch.

With the challenging layout complete, Royal K turned to Historic Floors of Oshkosh to cut the floor. "We could have done this by hand, but Historic Floors was really able to get this job into the budget," says Kroll. Royal K sent Oshkosh the layout and specified grain direction, and the floor and its blueprints were shipped back to New Jersey, where Royal K staged it out at their warehouse for accuracy. The floor was reshipped to the home, where installation took about 14 days. A natural stain and four coats of oil-modified urethane finished the floor. "We felt the oil base would bring out the richness in the bird's-eye maple, quartersawn oak and mahogany, and the whole job just came out perfect," says Kroll.

The whole job included not only this award-winning room, but wood throughout the entire home, except for the kitchen. Existing strip flooring was resurfaced, and extensive custom work and borders in santos mahogany and maple in a herringbone pattern were all installed.

It's the complex 550 square feet in this room that are the real showpiece, however, leading to Royal K's first entry in the Floor of the Year awards. "Every year we looked at the entries and thought, 'We could have won this,'" says Kroll. Suffice it to say that Kroll has already got a few things in mind for next year's competition, as well.

SUPPLIERS LISTED IN BOLDFACE ARE ADVERTISERS IN THIS ISSUE

Designer: James Monteforte | Installer: Keith Morrison | Finisher: Robert Fortune | Abrasive: 3M Co. | Adhesive: Bostik Inc. | Buffer: Clarke Industries | Finish: Sipersteins | Flooring: Historic Floors of Oshkosh | Sander: Harvester