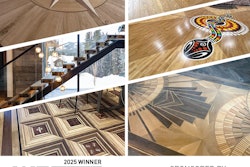

The patterns inside the octagons on this floor, seen from a distance, look machine-cut. Look closer, however, and you begin to notice each pattern differs slightly from the next. That’s because Victor Mulbauer, owner of Michigan Hardwood Floor Services in Farmington, Mich., carved each one by hand. The technique is called low-relief carving. After cutting an 11 1⁄2-inch-wide octagon shape out of 3⁄4-inch-thick maple, he carved the wood around the pattern design, resulting in a three-dimensional shape that pops off the wood but is the same height as the surrounding floor. The floor, which he installed in the living room at his home, begins with a hand-scraped, hand-carved walnut border made to look like a picture frame. Moving inward, there is a strip of maple and wenge, then 3 1/4-inch-wide maple plank. The wenge bordering the shapes inside the field symbolizes a rope—notice the twisting shape where the rope comes together between the shapes. Each piece of the floor connects via a glued tongue and groove, and the entire floor was glued to a plywood subfloor, then coated with UV-cured waterborne finish. With this showpiece floor and his NWFA Master Craftsman credentials, Mulbauer says he’s hoping he’ll begin attracting clients who ask for more than the typical, conservative wood flooring installation he’s done many times over. “I wanted to separate myself from the other guys,” he says. “Now I just want to do this outside of my house.”