When ordering chevron, know the angle of the chevron and the correct way to measure it, or you can end up with unpleasant surprises on-site.

When ordering chevron, know the angle of the chevron and the correct way to measure it, or you can end up with unpleasant surprises on-site.

Chevron is a classic parquet pattern that is becoming increasingly popular in many regions. It can come in many sizes as well as angles, which can create confusion among vendors and contractors as to the proper size to specify and where the measurement is derived. It's important to understand how to get a proper specification from the designer in order to get what you expect from your vendor.

The most accepted way to specify the length of chevron is to measure the length of one side of the board. I describe it as measuring from the long point to the short point on the same side of the board, as you see in the illustration here. (Note that for chevron, unlike herringbone, there's no rule about the length needing to be a multiple of the width—the points of chevron line up no matter what.)

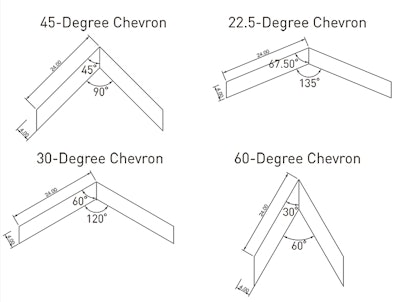

Then you need to specify the degree of the end cut on the piece. The most common angle is 45 degrees, but chevron is also often installed with a 22.5-degree, 30-degree or 60-degree cut. When we refer to the end cut angle, that is the angle you would think of if you were cutting the board yourself using a standard chop saw or angle gauge. The actual angle subtracted from 90 degrees is the specified angle and the angle you would set your chop saw or miter gauge to in order to cut the pieces.

Of course, for 45 degrees this does not matter since 90 minus 45 is 45! But for 22.5, 30, and 60 degrees you take the actual acute angle of the end cut and subtract that from 90 to specify the proper end cut angle. When ordering 22.5-degree chevron, the actual end cut angle is 67.5 degrees (90 - 67.5 = 22.5). For ordering 30-degree chevron, the actual end cut angle is 60 degrees (90 - 60 = 30). And when ordering a 60-degree chevron, the actual end cut angle is 30 degrees (90 - 30 = 60).

This can be quite confusing since the total angle of a right and left chevron piece will have an angle twice the actual acute angle as measured on the end cut, not the ordered angle. The practice of naming the chevron by the setting on a chop saw or angle gauge makes it clear to the manufacturer. It can be easier to understand when you look at the diagram of the common sizes of ordered chevrons.

As with any order, you need to specify the grading and cut, and quartersawn, riftsawn, and plainsawn are the standard cuts. Livesawn is becoming more and more common as a selection. This grade allows for tight cathedral grain in the center of the board with rift and quartersawn characteristics on the outer third of each edge.

It is also common to specify the largest open knot when you are ordering any grade that is not select or clear. With livesawn flooring, this can be very important to meet the customer's expectations and also to get what you want from your vendor. Leaving out these details can make for surprises that cause issues with your customer.

Finally, to avoid having too much waste and wasting money, I highly recommend doing a CAD drawing of your chevron layout before ordering.

|

Installation tips for chevron• Some people will tell you to snap lines and lay one course of chevron across the room. Personally I find that can bite you in the butt—I prefer to create a completely dialed-in plywood template 8 feet across that has the zigzag pattern you need. Snap your lines and use the template as a backer board to lay your starting pieces for your rows across the room. • If you get to a point while installing where you think you need to start cutting the ends of your factory-cut chevron flooring, DON'T. You'll start screwing yourself and the problem you're adjusting for will aggregate: 1/100 of an inch off here and there 10 times adds up to 1/10 of an inch. Back up and figure out where you're going wrong in your layout. • Your subfloor must be flat. Think about the fact that you're laying a two-dimensional pattern on a three-dimensional surface. Can you wrap chevron around a sphere? No, of course not. Any variations in your subfloor will create multiple ways that result in your miters looking off. • Know that, when milling wood, the smaller the pieces, the better the tolerances can be. As your chevron gets wider and longer, it's harder for the manufacturer to hold a tight tolerance.—D.A. |