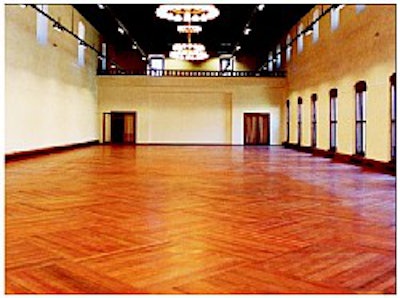

Congratulations. You just landed that first big job—about 20,000 square feet of Brazilian cherry— you'd been hoping for. The square footage is big, and your projected profit looks even bigger. But before you run out with all that cash and buy new vans for your crews, there are many things to think about. From job-site skills to cash management to organization, the realities of handling large jobs can be a shock. So before you sign that first giant contract, ask yourself: Are you ready to handle it?

Risky Business

On a large project, everything is magnified, not just your projected profits. Possibly the most important factor is your financial risk. If something goes wrong on a 700-square-foot job, it's usually a manageable hassle. If you have to resand the floor or even do a total tearout and reinstall, it may be a painful financial lesson, but it's one you'll probably get over. If you have to do that on a 15,000-square-foot job, however, that could be a financial hit that puts your company out of business.

When you're taking on a risk of that magnitude, your job-site procedures must be as by-the-book as possible. Steps such as documenting moisture readings and following the right sanding sequences are essential. Taking risks such as not preparing the subfloor well enough or rushing between finish coats are too much of a gamble.

To avoid situations where you feel pressured to take a shortcut or rush a job, with large jobs, build in much more time than you would expect. While you're at it, order extra materials. You don't want a big project coming to a standstill because you calculated everything so tightly that now you're one bundle short of the expensive exotic flooring your distributor custom ordered. You'll need extra of everything, from cleats to abrasive belts. If you schedule the job and order materials planning for the worse-case scenario, then you'll probably have just the right amount of time. If you do end up completing the job earlier, then your customer will be happily surprised.

Big Job, Big Money

General contractors who handle big projects—whether residential or commercial—are generally savvy types, and you'll typically have to sign their contract, not the other way around. These GCs are excellent negotiators, and if you don't have the confidence to deal with them and negotiate your terms, you're almost guaranteed problems. Price, unrealistic timeframes or working conditions, and tactics for delayed payments are all potential sticking points, so don't back down on these crucial aspects of the job, and append the contract to include terms such as timelines and working conditions. If the GC is insistent that you agree to unreasonable conditions, your best option may be to walk away. Above all, make sure your bid is high enough to accommodate extra time and manpower needed if you run into problems caused by other trades or otherwise difficult working conditions.

No matter how well you negotiate your payment, to accomplish a large job, you often need the financial wherewithal to handle paying for large costs upfront long before you get paid.

You'll be placing big orders for wood, abrasives, finish and other materials. For large projects, oftentimes you may be ordering more expensive materials or even custom materials. Once the job starts, your payroll expenses will be high as you cover all the personnel necessary to handle a large job site— you may need to hire extra staff or take on subcontractors to cover your schedule.

On a big residential job, you'll probably have some sort of initial deposit to help cover the costs. On a commercial job, though, you likely won't get your first draw until the job is well under way. Once the job is complete, if there is a problem, the GC may keep a retainage six months or even a year after the job is complete, even if the problem was caused by a different subcontractor.

To handle long droughts of cash flow—where you're spending big money but don't have any coming in—some companies try to schedule a balance between big commercial projects and a continual flow of residential work that provides a steady income. (Again, just make sure you have the workers to cover all those jobs.) Another option is to work with your banker to have a line of credit that covers lapses in your cash flow. (For more on lines of credit, see the article "Bank Buddies" in the October/November 2005 issue of Hardwood Floors.) You may also need to plan on the additional expense of buying more insurance. Many GCs on big commercial projects require that you have additional insurance over what you would normally carry.

Commercial Control

Commercial jobs often have other complications that contractors don't anticipate. An important one is safety. Commercial job sites are much stricter about safety requirements than typical residential jobs. OSHA regulations such as wearing long pants, hard hats and work boots must be carefully followed. GCs on commercial jobs will sometimes require the subs to sit through the GC's classes about OSHA regulations and the GC's own procedures on the job site, such as who to go to with problems. The GC may also require that the sub have a job-site supervisor who has attended an extensive OSHA class on the job full time, and that any workers on the job site have attended a shorter OSHA class.

Commercial GCs control many other aspects of the job: They may dictate not only the safety training of the workers on the job, but also how many workers they expect to be on the job every day. And for both commercial jobs and sports floors, there may be a very tight window of time when each sub is allowed on the job site. Those windows sometimes dictate unusual schedules, such as working through the night. Job-site access might also be restricted by factors such as having to reserve elevators and loading all equipment and materials on carts to get to the site.

Job-site conditions also may be less than ideal on large jobs. Even if the contract or specifications detail that the HVAC system be running, that may not be the case. The project owner may not want the system's warranty being used up during project construction. On many gym jobs, which are often in older school buildings, there may be a poor HVAC system or no system at all. In such cases, contractors do the best they can with the conditions by using existing doors, windows and fans. Those who often work on gym floors sometimes use giant turbo fans to create air flow, especially during hot, humid months when the majority of gym work takes place.

Protecting the job site from other trades or even the general public can be challenging, but it's essential, so extra effort may be required to talk with the GC, school administrator or project leader to make sure random people aren't walking across your wet finish.

Constant communication with the project manager— before, during and after the job—is a good idea, and written notes are best. Keep a daily log detailing the day's work. Any change orders must be in writing—if not, don't expect to get paid for the change, no matter who told you to do it.

Equipment Check

Wood flooring contractors who work on large jobs often use different equipment to make their jobs easier and faster.

Especially on gyms, some contractors use 12-inch drum sanders instead of the usual 8- or 10-inch machines. Such machines need a dedicated line, and not all distributors carry the paper for them, so planning ahead and ordering enough abrasive can be important when using them. For huge gyms, riding sanding machines are even available. Contractors who do a lot of gym work also need line taping machines and the training to use them.

Finishing on large jobs requires some extra thought, and sometimes different applicators are helpful. For waterborne finish, 24-inch T-bars are often used instead of the 12- or 18inch versions. There are also applicators available with a tank that holds finish. A valve controls the finish that is poured from the tank in front of the applicator, eliminating the need for pouring lines of finish by hand. This style of applicator is most often used with polyurethane, but it is also sometimes used for waterborne finish.

Whether the job is a big residential, commercial or gym job, finishing a large area requires some extra thought and planning. Sometimes a certain product may be specified that you haven't worked with before. It goes without saying that if you're going to use a finish you haven't applied before, you should experiment with it on a smaller area first before using it on a huge job. As mentioned, the HVAC situation can be challenging, so plan ahead to address that as well as you can with the situation you have.

On any job with multiple rooms, you need to figure out a strategy for where to start and end your finish application so you don't finish yourself into a corner. On a large-scale project, that strategy can be more complicated. How much finish you'll be able to apply in a day will be determined by how many workers are on the site, their skill levels, the applicators used and the types of finish you're using. Try to realistically estimate how much can be accomplished in how many hours, then stick to a plan for that day, making sure the whole crew understands the plan.

Because the flooring will cover large uninterrupted expanses, finishing techniques such as using tape lines across board edges and at doorways may be necessary to disguise where finishing ended one day and began the next—figure that out before you start applying finish. The flooring installed also may dictate the timing: Some products, such as some oily exotics, need to be coated immediately after sanding before their natural resins migrate to the surface of the flooring. If you have a huge job with such a species, you need to coordinate your entire sanding and finishing schedule to be able to accomplish that with the workers and equipment you have available.

Once you analyze your skill level, number of employees, financial readiness, risk tolerance and many other factors, you may find that shooting for a smaller number of bigger jobs is the direction you want to pursue for your company. If you're ready, the benefits can be great: less running around working on a living room here and a bedroom there, less time spent chasing collections on many smaller bills, fewer potentially difficult customers, as well as a large amount of income at the end of the job, among other things. Just be prepared before you take the plunge.

Sources for this article included Angela Crowl, Dominic A. DiFebo & Sons; Leonard Hall, Endurance Floor Company; Frank Kroupa, NWFA; and Ken Schumacher, Schumacher & Co.