As owner of two businesses, National Wood Floor Consultants Inc. and Reichow Parquet Flooring Inc., it's fitting that Roy Reichow's home base is the Twin Cities metro area, which gets its nickname for its two largest cities, Minneapolis and St. Paul. In reality, there are 186 cities and towns that make up the area that is built around the Mississippi, St. Croix and Minnesota rivers. According to the U.S. Census Bureau, in 2006 the Twin Cities had an estimated population of 3.5 million, making it the 15 th largest metro area in the country. Its growing population and increasing wealth provide many opportunities, but there are also many challenges to running a wood flooring business here, including the slowing economy, urban and suburban sprawl, bottleneck traffic and harsh climate fluctuations. One bitterly cold, snowy December morning, Hardwood Floors spent a day with Reichow to get a glimpse of his flooring businesses in the Twin Cities.

5:30 a.m.

Reichow starts his day from his home office in East Bethel, Minn., which is about 30 minutes north of the metro area. In order to avoid the heavy Twin Cities traffic, he spends one to two hours of the day reviewing the day's schedule and catching up on paperwork. This typically entails research and report-writing for his inspections.

Sometimes the only chance he has to contact contractors about pending inspections is at 6:30 a.m., so he also may make a few phone calls.

6:30 a.m.

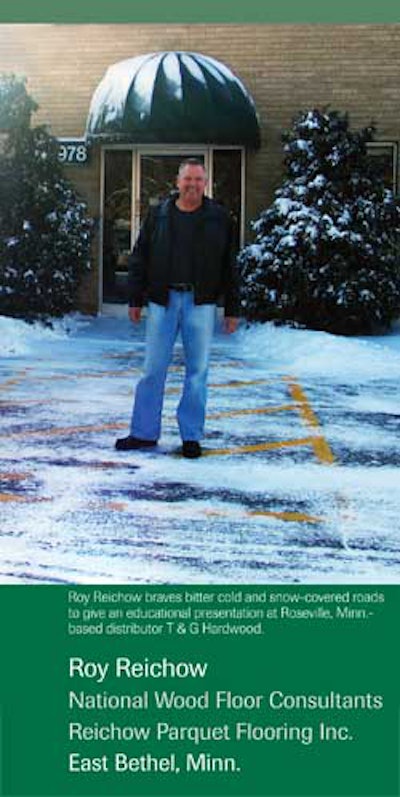

Reichow leaves his home and heads for Roseville, Minn., a St. Paul suburb where he is giving an educational presentation for wood flooring distributor T & G Hardwood. Reichow says he sees more companies like T & G taking a proactive approach in educating their staffs despite the down economy. The philosophy is that education saves money in the long run by reducing complaints and failures.

Today turns out to be a challenging commute. Reichow battles gridlock traffic, which is moving at a snail's pace due to the slick roads from the storm that dumped more than 5 inches of snow in the area overnight. Adding to the problem is the bitter cold and strong winds: a bone-chilling -7 degrees Fahrenheit with a wind chill of -29.

7:45 a.m.

Reichow finally arrives at T & G safely. He checks in with the T & G staff about what he needs for his lecture. The lecture was originally supposed to start at 9 a.m., but some employees called in to say they were running late because of the weather. The delay means Reichow has time to grab a quick breakfast at a café down the street with his guest journalist.

8:10 a.m.

Reichow takes a call from a subcontractor and works out the details for a job that has been pushed back a couple of weeks. Prior to the economic downturn, which started affecting his business about two years ago, Reichow had six employees, but now he uses three to six subcontracting crews. Reichow found that he was losing money by paying guys to sit in the gridlock traffic, and it was expensive to pay benefits when work wasn't constant. High turnover rates and the need to constantly train staff were also frustrating. "Employees used to be with you three to five years, now it's one to two years," he says.

8:30 a.m.

Reichow checks his e-mail from his phone and notes some schedule changes from his wife, Michelle, who is vice president of Reichow Parquet Flooring.

9 a.m.

Reichow returns to T & G to set up for the lecture. He gets out his computer, projector, printed materials, wood samples—and a bowl of water.

9:30 a.m.

The T & G employees gather for the education session. Reichow talks about the supply chain of wood flooring and how information is often lost through the distribution channels. He also addresses the importance of educating salespeople so they can supply the customer with the right wood flooring for the application. He hands out sample questionnaires he uses to narrow down the product selection. Reichow then discusses causes for failed installations and shows photos of floors he's seen on inspections. One floor was an exotic wood that cracked from moisture fluctuations. He demonstrates the difference in fiber densities and moisture absorption between domestic and exotic wood flooring by dropping pieces of flooring into a bowl of water. The Douglas fir sample floats while the Cumaru sinks; the lesson being that acclimation times may vary by the product and species.

Reichow also discusses the topic of microclimates, explaining that moisture and relative humidity can vary by regions, local conditions and even different rooms of a home. He tells them that the top floor of a commercial structure may be 15 to 20 percent less humid than the lower floors. His point is that you have to know your conditions well and that you can't assume one moisture reading will be enough for the job.

The training and education aspect of Reichow's business happened by chance. In 1974, Reichow formed Reichow Parquet Flooring, specializing in installation, sand and finish work. He has seen the market evolve over the years with many new players, new types of flooring and, as a result, many failed floors. "I remember a flooring distributor asked me to stop by and look at a project. When I arrived we had seven people on site, all looking for answers about why this floor failed," Reichow recalls.

"Before I left I was explaining the dynamics of movement due to moisture." In 2002 he formed his inspection company, National Wood Floor Consultants. He is an NWFACP-certified inspector who also teaches in many different settings for flooring contractors, insurance companies, restoration professionals and builders' associations. Being one of only a handful of certified inspectors in the region, his work for National Wood Floor Consultants now accounts for about 30 percent of his time, with education becoming increasingly popular. He is slated to present to the Builders Association of the Twin Cities in March.

10:30 a.m.

The lecture ends, Reichow packs up his gear and changes out of his dress clothes into jeans and a comfortable shirt for the upcoming flooring inspection. Reichow discusses the job with T & G's President Gregg Patterson and Sales Manager Mary Ellen Kollmer. T & G supplied the flooring for the job installed last year, and now the homeowner is complaining that the glue-down engineered santos mahogany is coming up in two places on the floor. The report says that the flooring was glued directly over lightweight concrete, and Reichow has an idea as to what the problem could be, however, he doesn't say anything and prepares to go into the inspection with no preconceived notions.

10:52 a.m.

Reichow gathers the paperwork for the inspection and heads out near the Minnesota/Wisconsin border to Lake St. Croix Beach, a town just off the St. Croix River.

Reichow averages about 150 to 200 miles per day driving around the Twin Cities metro area. Over the years the radius he covers around the city has grown larger as new construction has expanded farther beyond Minneapolis and St. Paul. With the recession, Reichow now takes jobs even farther out than he used to.

The current economic slump has impacted Reichow's businesses, but he feels he can weather the storm. He lived through the recession in the early '80s and has learned some valuable lessons for surviving tough economic times. "Back in '79 to '81 during the recession I had a lot of new construction, and when the bottom fell out we were settling for 50 cents on the dollar," Reichow recalls. "Since then, I've diversified and split the business up between new construction, remodels, and sand and finish," he says. Reichow has also has diversified his business with the addition of his inspection and education services through National Wood Floor Consultants. He says continuing education, diversity and minimizing debt is the key to survival in tough times. Reichow also feels his involvement in the NWFA and its educational programs have given him the tools and knowledge to be competitive in such a tough market.

11:30 a.m.

Reichow arrives at the inspection site, a newly remodeled home near the river, and is greeted by the homeowner and the flooring contractor. Reichow carries in his notepad and a large black case with inspection tools into the home, removes his shoes and asks to see the problem areas on the floor. They point out an area by the stove and an area in the hallway where the 3/8 -by 3 5/16 -inch santos mahogany engineered floor is not adhered to the subfloor.

Reichow lets the men know that he will need to know the mixture of the lightweight concrete and what sealer was used on the concrete. It turns out that the homeowner was the builder, so the homeowner calls the concrete sub to find out the information. The homeowner insists he's "sure" that the concrete was sealed.

11:40 a.m.

Reichow gets out his tools and begins to inspect the entire floor. He confirms that the problem is isolated to those two areas. A board had already been taken up in the kitchen, so he can easily check out the concrete and the flooring in that area. Reichow numbers each board with blue tape so he knows where to put them when he reassembles the floor. He puts markers down on the concrete where the adhesive isn't bonding with the flooring and takes photos. He checks the underside of a removed board and notices mineral residue on the flooring adhesive. This indicates that there was still moisture in the concrete at the time of installation, and the minerals/salts brought to the surface only provided a marginal bond. Reichow states that he will need to know the pH test results from the flooring contractor and the water/cement ratio from the cement contractor. The homeowner looks puzzled but is sure that the contractors have that information.

Upon further inspection, it turns out that lightweight concrete wasn't used after all. Reichow takes moisture readings of the subfloor and the boards and records the numbers in his notebook.

12:15 p.m.

Reichow notices that the problem area in the kitchen is near a vent and that the floor is very warm. There is radiant heat, but Reichow explains to the homeowner that if you can feel the heat, it's warmer than your body temperature at 98.6 degrees and at a point where adhesive may not properly bond with the flooring. Reichow also notices that the flooring is partially overlapping the vent and that hot air blows under the flooring.

Reichow and the flooring contractor head down to the basement to take a look at the heating system and inspect the pipes below the flooring. He finds a tankless heating system and a maze of pipes on the wall. He notices that one line of pipes is warmer than the others, and he follows it along the basement ceiling to where the problem areas are in the floor above.

Reichow then goes back upstairs to take more readings on the floor. He pulls some string along the length of the hallway and finds that it's within an acceptable tolerance for flatness. When the owner tells the men that he keeps the master suite's floors warmer than the rest of the house, Reichow checks the suite and notices another hot spot on the ceramic flooring in the closet. Reichow tells the two men that he recommends having the heating system checked out by the HVAC contractor. Reichow also needs to contact technical support of both the flooring and adhesive manufacturer to get more information on how the heat and/or the minerals from the concrete could affect the adhesion.

1:25 p.m.

Reichow packs up his gear and tells the men that he will be in touch with more questions. In addition to needing more information from the adhesive manufacturer, concrete sub and the HVAC contractor, Reichow needs more information on installation techniques from the flooring contractor. The standard form of inspection questions he has is comprehensive, and it is further proof that every contractor needs to cover himself with well-documented procedures of every aspect of the installation.

1:30 p.m.

Reichow grabs a bite to eat in the nearby resort community of Afton, Minn., before heading back to the metro area.

2:25 p.m.

Reichow checks e-mail on his phone and finds out that he has two new inspection requests. He e-mails them back and lets them know that he will need a deposit before he can proceed. Reichow explains that he now does most of his inspection business by credit-card payment, because customers may not want to pay if they dislike the results of the inspection, and a credit card makes it easier to collect the money.

Reichow says this inspection was fairly civil, but some can get pretty heated as parties involved play the blame game. As an inspector, he acts as a disinterested third party who often has to play mediator. "My job as an inspector is to walk in and collect the required data needed. It's not open for discussion unless I ask a question," he says. Almost all of his correspondence is done through e-mails so everything is in writing, which makes it easier to look at the documentation and accountability to determine who's responsible. He has seen contractors and builders take big hits for not following basic procedures. Sometimes the findings result in legal action, and he has to testify in court.

The biggest challenge with being an inspector while still being a wood flooring contractor is that some people view it as a conflict of interest. "It's taken me three years of working closely with the distribution centers, the dealers, the pro dealers, etc., to show the value of the education process and working as an inspector," Reichow says. "I was not well received by them because I was viewed as a competitor. But they soon realized that I could separate myself from the competition part of the installation side and work strictly on the inspection side to be able to look at the problem at hand." Part of earning that trust is to have two separate companies operating independently of each other.

2:30 p.m.

Reichow heads back to the interstate and drives toward T & G. He calls into his office and talks with Michelle about ongoing jobs and scheduling. Two jobs originally scheduled for the week were postponed and will have to be rescheduled for after the holidays. The two weeks before Christmas used to be the busiest time of the year for Reichow, and employees used to log between 50 and 70 hours per week, but now with the slowing economy, he has seen a lot of the pre-holiday business drop off. People are putting projects off or downgrading to a recoat rather than sanding the floor. "People just aren't in a rush to have their flooring done like they used to be," Reichow says.

3 p.m.

Reichow arrives back at T & G and checks in with Patterson and Kollmer again. He gives them a brief rundown of the inspection and then heads back out to go to his resand-and-finish job. Although this isn't a fancy floor with borders, medallions or inlays, Reichow has found these basic jobs to be the bread and butter of his business. He still does contracting work himself, but most of the jobs are on a smaller scale because he's so involved with education and inspection. "I don't have the time to devote to 3,000 feet; I'll put my subcontract labor on that," he explains.

3:40 p.m.

Reichow arrives at the job site, in Rogers, Minn., a suburb in the northwest corner of the metro area. Because heavy snowfall was predicted over the weekend, Reichow dropped off the big machine and his tools at the job site the previous Saturday. That way, he didn't have to worry about trying to maneuver the equipment through the snow and ice. Reichow changes into his work pants and T-shirt and then assesses the floor.

Reichow tapes off the work area and then installs two wood vents before sanding the kitchen, dining and entry floors.

The customer had complained of dog scratches in the dining area of the kitchen floor, but dark spots on the floor were the most evident problem. The original poly had peeled off the floor, and it looked like the homeowner had used a cleaner that discolored the floor. Reichow is concerned that there could be contaminants in the wood that could interfere with the new coat of finish, so his plan is to first cut the floor with a 40 grit and then wash the problem areas with lacquer thinner before making his second cut tomorrow.

6 p.m.

Reichow packs up his things and begins the 40-minute commute home.