Most wood flooring contractors know the importance of maintaining the big sanding equipment they use every day, but sometimes the smaller items such as nailers, electrical cords, saw blades, switches and compressors can get overlooked. Although these items are small, they can cause big losses if one malfunctions and you suffer downtime while trying to replace a part. A simple $10 part could cost you hundreds of dollars while you scramble to find a replacement.

I've been repairing machines for 15 years, and it's amazing to me how poorly I see some contractors treat the tools that make them their money. When I get repairs in my shop, I can easily tell if guys aren't taking care of their tools. I always say that a well-maintained, less-expensive tool is better than an expensive tool that's not properly maintained. A few simple steps can keep these tools working correctly and help keep your business profitable.

Supply List

- Vacuum

- Air compressor

- Air filter

- Oil

- Saw blades

- Drill bits

Step 1a

With small tools, more than 75 percent of the repairs I see are electrical-related. A simple way to maintain your electrical cords on vacuums, saws or other equipment is to unplug the cord at the wall (not from 10 feet away) and wrap it around the machine.

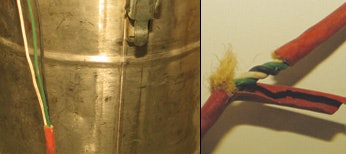

Step 1b

Don't wind the cord up and wrap it around your hand—this could cause permanent kinks and eventually damage it. The copper wire in electrical cords is flexible, but over time, it can break. If you don't wind and store your electrical cord properly, it could become permanently kinked like this one ...

Step 1c

... or frayed like these cords. This can restrict the voltage to your machines, causing them to malfunction. It also generates heat and causes the parts to burn, potentially ruining the motor on larger machines. Damaged cords are a safety hazard, and they put you and your workers at risk for fire or electrocution.

Step 1d

Every week, check for breaks, kinks and twists, and replace cords before they become dangerous. Here, the cord is starting to kink.

Step 1e

Yanking the cord out of the wall can lead to bent plugs like these. Also notice that the ground has been removed—something you should never do. If a tool malfunctions, the ground is what protects you from an electrical shock.

Step 2

Dust is a common cause of damaged parts. Switches on equipment such as saws, vacuums and edgers can become worn and eventually not function if they become filled with dust and dirt, like the one pictured above. After every job, thoroughly blow off the dust from the switches. Also, if a switch isn't functioning properly, don't try to force it or add lubricants such as WD-40, as one contractor tried to do with the switch in the inset photo above.

Step 3

The inside of this saw shows how gears and motors can also get dirt and grit trapped inside, causing them to malfunction. Blow the dust off daily. Also, let the tool do the work for you—don't force it. Overworking the tool could shred the teeth off the gear.

Step 4

It's important to keep all of your saw blades and drill bits sharp. The used carbide blade on the left is black from excess heat, and its teeth are dull. Compared with the new blade on the right, it's easy to see the difference. Check saw blades daily, or as soon as you notice they're not cutting properly, and keep spares on hand. In this case, replacing a $15 blade could've prevented damaging a $250 saw, which is now irreparable.

Step 5a

Lubricate your nailer with a couple drops of oil daily to prevent rust from forming. The cylinder should be free from rust (like this one). Rust tears up the rubber O-ring on the piston and causes wear.

Step 5b

Dirt and debris are also a major cause for wear on nailers.

For nailers to function properly, the piston should be clean (like the bottom one in the top photo). In addition to blowing off dust daily, replace the filter on the air compressor monthly. The filter helps keep much of the dirt away from the piston, as you see in the inset photo. The cost of an air filter (usually around $2) is a wise investment to keep both your compressor and nailer running smoothly.

Step 6

Another important step with your air compressor is checking the oil daily.

Most models hold only about 1/2 cup, and that can easily be used up after a busy day on the job. Refer to the manufacturer's specifications for details on your model.