Coming up Short

Why does it seem like I’m always short on flooring when I get to the end of my installations? It seems like the manufacturers are shorting me.

Glen Miller, manufacturer division manager at the Chesterfield, Mo.-based National Wood Flooring Association, answers:

It is commonly accepted that you need to add at least a minimum of 5 percent for waste to the square footage you measure for each job. Manufacturers are not in the business to shortchange anyone on the actual footage; if they were, more than likely they would not be in business long.

The waste allowance can change depending on which flooring you’re using. For flooring equal to No. 1 or better in grade/appearance, multiplying the square footage by 5 percent is generally accepted. Using lower grades/appearances, using shorts or using plank typically requires multiplying 7 to 10 percent (or even more for wider plank). If you are installing on a diagonal or in an irregular room, multiply by no less than 10 percent.

This is not to say that the footages may not be short sometimes from the manufacturer, but, in general, the footage will meet the stated amount. If there truly is a shortage, then you have all rights to be upset. Contact the distributor first, and then the manufacturer, to get things taken care of.

Avoiding Dishout

What can I do to make sure I don’t dish out the grain when I’m sanding?

Roy Reichow, president at East Bethel, Minn.-based National Wood Floor Consultants, answers:

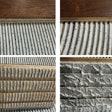

Dishing out the grain of the wood, also sometimes referred to as “shellout” or “dishout,” is commonplace, yet it is preventable at the time of final sanding.

In many cases this problem can be caused by the drum sander removing springwood prior to the buffer ever seeing the floor. Many floor sanders use too much drum pressure on the final cut to remove sanding marks from the previous cut, and shellout begins. This usually happens when a floor sander is trying to stretch out the distance on ceramic-type sandpaper. Sanding across the grain or sanding two adjacent species with different hardnesses (such as walnut and oak) also can create dishout.

Other problems are over-screening and over-padding the screen (with a 1-inch white pad, for example). True hardplating (with a bolt-on or double-sided disc) is pretty much a thing of the past; today, soft-plating or medium-plating using 100- or 120-grit paper backed by a 3⁄8-by-16-inch white pad for the buffer is often used. With this technique, the paper is pliable enough to do the job, yet rigid enough to avoid shellout. With this soft-plating system, you can both eliminate shellout and the use of screens before stain.

Noise Reduction

I’m bidding my first multi-level condo building. What do I need to do about soundproofing?

Scott Coll, CEO at Austin, Texas-based Commercial Flooring Systems, answers:

For many high-end multi-family residences, soundproofing is big business. Surprisingly, sound waves travel faster through material such as wood than they do through air. There are two measurement systems used for noise when it comes to flooring: Impact Insulation Class (IIC) and Sound Transmission Class (STC). IIC is the impact noise that is transmitted through a floor/ceiling assembly. STC is the actual sound in a room. The higher the IIC or STC rating, the better the noise reduction, with 50 considered the minimum for multi-family dwellings (always check to see if the rating is more stringent for the project you’re working on).

Keep in mind that a key factor in sound reduction is the total mass of the subfloor and the ceiling layers: each doubling of the total mass increases the IIC and STC by about seven points. Increasing the thickness of the sound-absorbing material increases the IIC and STC ratings. So, when thinking about IIC and STC ratings, you have to consider the entire subfloor and ceiling.

When using an engineered wood floor where sound control is a concern, one of the most common methods is to use a floating floor over a 2-mm underlayment foam.

A newer solution for sound control is using polymer-based wood floor adhesive that not only holds the material to the floor but also has sound absorption qualities, with excellent IIC and STC ratings. These products also repel slab moisture at an extremely high level and have no water, solvents or Volatile Organic Compounds (VOCs).

Whichever method you use, keep in mind that the floor must not have contact with walls or baseboards, which transmit noise to other parts of the building or surface.