When you deal with adhesives, you’re spending a lot of money for a bucket of glue. High-performing adhesives are in the $200 range if your adhesive has moisture mitigation and/or sound control. You need the performance you’re paying for, and to get that, you need the right transfer.

Three geeky adhesive terms

Uncured adhesives are fluids, not solids. Adhesive manufacturers study their fluid properties and recommend the trowels for each adhesive. We study:

Viscosity: This is how resistant a fluid is to flowing. For example, peanut butter is a fluid—you can spread it, but it’s very viscous (thick). Different adhesives vary in viscosity.

Rheology: This relates to how materials deform and flow under stress—for us, this correlates to how hard it is to spread. A good example is whip cream: It’s very viscous (you can’t pour it out of a container), but it’s extremely easy to spread. An adhesive could have low viscosity (be easy to pour) but its rheology could be off, so it is hard to spread.

Thixotropy: For us, this means how well the adhesive holds it shape—its ridge—after being spread (i.e., anti-slumping). The more thixotropic an adhesive, the more it will hold its ridge.

Your trowel is a gauge

The trowel is a tool to gauge out the amount of adhesive on the floor. Every manufacturer makes a claim about their glue and what square footage a gallon will cover. Some flooring adhesive manufacturers say you must use a specific trowel, while others recommend a few.

What’s crucial is the actual transfer of the adhesive to the backs of the boards. Many adhesives require 100% or 95% coverage of the concrete—that’s where you mitigate moisture and/or sound. But you also need the right transfer to the boards.

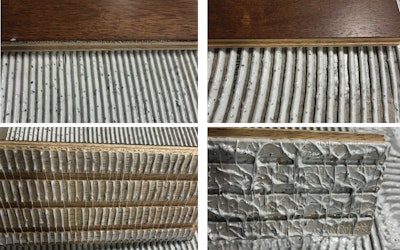

Even a perfectly flat substrate doesn’t guarantee transfer. With a small trowel, you might have peaks that are ⅛-inch or ¼-inch tall. And if you have, say, a 6-foot-long, 8-inch-wide solid board with kerfs, those adhesive ridges won’t go up and fully embed to cover the back of the board.

When I go to a job site that claims there’s a failure, I flip a board over, and it’s usually a transfer issue. I don’t mean it should have 95% transfer and they have only 93%—more like they’ve got 40% transfer with large voids.

Always test your trowel

I recommend testing your trowel before you start to make sure you’re getting the transfer you expect with that specific adhesive, substrate and flooring. Before you start the whole job, spread some glue, install a piece of flooring and flip it over. What you find might prevent trouble down the road.