Now more than ever, there’s a daunting variety of products to choose from related to moisture mitigation, underlayments, patching, skimming and wood floor bonding when you are doing a glue-down wood flooring installation. Figuring out which products to use can be confusing. Here are some factors to consider:

Moisture protection: A glue-down wood flooring installation begins with measuring the moisture of the subfloor, where moisture vapor emissions can pose a threat. Destructive moisture effects could appear at the time of the installation or months or years later, so it’s critical to establish the right foundation early by protecting the wood flooring from potential moisture. Traditional countermeasures have included epoxy moisture barriers or plastic sheeting that is usually semi-permeable. Newer products include two-part epoxy and single-component polyurethane resin moisture barriers, which are engineered to provide moisture protection in addition to substrate consolidation and adhesion promotion; these products are fast-curing (in as little as one to three hours).

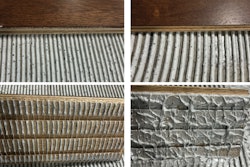

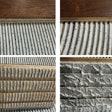

Flattening the subfloor: The industry specifications for a glue-down job require that the subfloor be flattened to within 3/16 inch in 10 feet or ⅛ inch in a 6-foot radius. This often entails removing high spots by mechanical means and filling low spots with cement-based patch mixes. Newer options include cementitious self-leveling underlayments that are rapid-setting (with cure times as fast as 90 minutes) but also durable and capable of handling unlimited moisture.

Adhesives: Most often, conventional wood flooring adhesives have a urethane or polymer base and provide an adequate bond for the wood floor. Today there are also all-in-one wood flooring adhesives engineered to complement the other components of the installation; some also offer unlimited subfloor moisture vapor protection and may have sound reduction and other benefits. When using an all-in-one product, keep in mind that you must ensure complete coverage with the correct trowel per the manufacturer’s instructions.

Systems: Just as with stains and finishes, it’s safest to go with a systems approach, using a line of products engineered to perform together. When used as intended, this ensures you are covered by the products’ warranties. When it comes to adhesives, you may choose different systems that cater to different needs, such as rapid installation times or project profiles with particularly demanding sound or moisture control requirements.