Customers have myriad options available to them when they choose their floor coverings. Once they've sorted through the options and settled on wood, many may not realize that once again, they're entering what can be a maze of alternatives. Before most even begin their attempts to decipher the finish types, widths and patterns available, they want to choose which specie they need. It's up to you, the wood flooring expert, to guide them through the process. Before you do that, however, be sure you're up to speed on species basics.

Along with looking different, species also move at distinct rates in response to moisture, resist dents with varying strength and have their own quirks regarding workability on the job site. For contractors who always work with oak flooring,using a different specie can be a bit of a shock when they discover the wood is nearly impossible to cut, doesn't take finish or leaves huge gaps after installation. An experienced wood flooring contractor talks about different wood flooring species as if each one has its own personality — some are forgiving, some are fussy, and some are incredibly frustrating. Just as with people, the key lies in being able to figure each one out so you can work with them successfully as individuals.

On the surface

The most obvious difference between species is how they look. In today's market, wood flooring seems to come in just about every color. Along with color, the appearance of each specie is different due to the prominence of grain patterns and character marks.

Grain patterns and character marks vary not only between species, but also between different grades and cuts of species. Depending on the specie chosen, you may or may not be able to guarantee a grade, and therefore, the appearance of the floor. Many domestic species are graded by an impartial third-party association, such as the National Oak Flooring Manufacturers Association or the Maple Flooring Manufacturers Association, and therefore lend some guaranteed predictability to the appearance and milling. Most imported species and some domestic products can be more of an unknown. Along with grade, different wood flooring cuts — plainsawn, quartersawn or riftsawn — also affect the grain's appearance.

With some species, things may not always be as they appear. Certain species — domestic and Brazilian cherry are two obvious examples — are very photosensitive and change colors dramatically as they age. Be aware of each specie's sensitivity, and make the customer aware of the color the floor will actually be. This is also an issue when covering a floor on a job site or placing area rugs in the home — some species may need only days for you to see the difference in light exposure on the floor.

On the move

Color and grain aren't the only factors that affect appearance. If the first time the customer turns the heat on, the floor shrinks enough to lose a small family pet in between the boards, the appearance of the floor is going to be an issue with the customer.

In the world of wood, the way it behaves in response to moisture is referred to as "dimensional stability." All wood is hygroscopic, that is, it swells with moisture and shrinks in the absence of moisture. Just how stable (or unstable) it is depends on what the specie is. Some seem relatively unaffected by humidity or dryness, while others may seem to fluctuate wildly in response to the environment. Species also vary in how fast they respond to climactic changes. Some species may need much longer than the typical acclimation time before they can be installed, sanded and finished.

If a customer is set on having a certain unstable specie in his home but is going to be unhappy about the separations that appear between all the boards as winter approaches at his Michigan home, he needs to be aware that humidity control in the house is a necessity.

Likewise, the opposite problem can happen — wood can absorb moisture from its environment and cup, which tends to make customers even more unhappy than large gaps. If, for example, a contractor takes some flooring that is kiln dried to a moisture content of 8 percent and installs it in a beachfront Florida home, knocking it in nice and tight, he can expect a call from an unhappy home owner lamenting his now-overcrowded flooring. But again, just how severe this reaction may be depends on which specie is installed.

An exception to this is engineered products. Due to their cross-ply construction, engineered products —no matter what the specie — are much more dimensionally stable than their solid counterparts, and most don't need to be acclimated at the job site before installation. Along with that, most do not show great changes with swings in humidity after installation.

Remember, too, that flooring tends to expand across its width, not length, and that quartersawn flooring is much more dimensionally stable than plainsawn products.

Hard as nails.

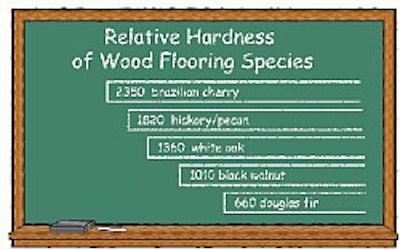

Another factor that helps distinguish one specie from the next is its hardness. The hardness of wood is referred to as "side hardness," or "Janka hardness." It represents the resistance of the wood to wear, denting and marring. The actual Janka test measures the load required to embed a 0.444-inch steel ball into half its diameter in wood. Just as species run the gamut in color and stability, they are all over the charts in terms of hardness, with many imported species characterized by their high hardness ratings. Because of this, each specie needs to be considered individually while it is being sanded. Experienced sanders use a slightly different grit, sanding sequence and/or procedure depending on which specie is used. Multiple species used together can be a recipe for disaster if the contractor doesn't take care to not dish out the softer-grained woods next to harder species.

Making it work

As with people, some species are easy to work with; others may make you want to tear your hair out. Some woods are so hard sawing them can be a challenge and trying to nail or staple them may split the flooring tongues. Slightly changing the angle of the point of entry can help, as can blunting the ends of fasteners. Some species are so hard that holes may have to be drilled to be able to nail the floor.

Once the floor is down, sanding variations need to be considered for each specie. Not only do they vary in hardness, but some species, such as heart pine, tend to quickly load up abrasives with resin, and can leave you scrambling for more sandpaper if you're not prepared.

Wood dust of some species can cause problems. Some people are highly allergic to certain species, especially some exotics (although some people are even allergic to red oak dust). To help avoid problems, always wear respirators, eye protection and long sleeves.

Not surprisingly, finishing needs vary from specie to specie. Some species have resins that can inhibit drying times; others can turn unexpected colors with certain types of finishes. Experiment to find out which types of finishes work best and look the best with the wood you want to use. It's imperative that if the customer wants a stained floor, you be sure that the stain works with the chosen specie (maple, for example, is notorious for taking stain in an uneven pattern). The best solution is to use a specie that is naturally the color you want and thereby avoiding the staining process entirely.

Familiarize yourself

The only way to be successful in working with the seemingly endless array of species is to get to know each one on a personal basis. Before you begin a job with a new specie, find out as much as you can about it from the supplier and from fellow contractors who have worked with it before. Most important, make a sample panel far enough ahead of time to find out everything you need to know. That way, when the time comes, you can be sure you and the new wood will get along.

For more on dealing with imported species, see the Techniques story “Going Global” on page 43 of the August/September 2000 issue. For more on working with maple floors, see the Techniques story in this issue on page 41.