It'll waste time. It'll cost money. It's a hassle. These are all common, but bad excuses for why some contractors don't practice safety on the job site. A century ago, it was common practice for companies to operate with total disregard for employees' health (the life expectancy was also decades shorter then). As we enter a new century, attitudes have changed. Employers are realizing that healthy employees are productive employees who lead to better profitability for the whole company.

Not convinced. As we begin the year 2000,consider a New Year's resolution to make your company a safer place to work. If you need more encouragement, check out the following reasons for practicing safety on the job site.

1) Save money

This may not be the most touching reason to implement better safety procedures at work, but it's one that grabs most business owners' attention. If for no other reason, look at the bottom line. Don't see it. Consider this: Every time a worker is hurt, it costs the business money. Maybe he's only slightly injured, and he "takes it like a man" and keeps working all day. He's still not as productive as he would have been 100 percent healthy. Or maybe he's more seriously injured — there's all that time (translate: production) lost while he's going to the doctor or emergency room. He's probably not going alone, so his coworker misses hours that day taking him to the doctor. If other workers are left behind on the job site, there's the demoralization factor, too — coworkers who have just seen their buddy get hurt, especially seriously, are not productive.

Accidents requiring time off are even more costly. Maybe the other employees are scrambling to cover someone's work, which makes for tired, stressed-out, unproductive workers. If another employee must be hired, time is wasted in the hiring and training process.

2) Save more money

That worker who had to be taken to the hospital. His insurance claim and every one like it are driving up your insurance premiums for medical, worker's comp and disability insurance. On the contrary, if your workplace is accident-free, that ultimately results in lower insurance costs.

3) Save even more money

Don't have that MSDS sheet on the job site. Got an illegal power hook-up to your big machine. The Occupational Safety and Health Administration will be happy to fine your company for every infraction.

Wood flooring contractors have gone out of business solely because they couldn't pay the thousands of dollars in fines levied by OSHA. Some regulations that you may not be aware of (they apply to all companies, regardless of size):

• MSDS (Material Safety Data Sheets) must be present on the job site whenever there are hazardous chemicals present (these are available from the products' manufacturers).

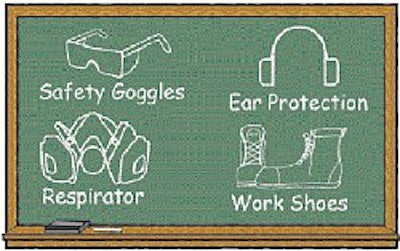

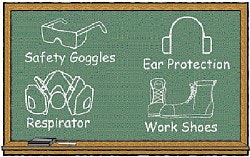

• Appropriate personal protective equipment (hand, eye and respiratory protection) must be used.

• All employers must provide a written safety plan for their work functions. This includes, among other things, accident reporting, training and documentation and hazardous substance control.

These are just the tip of the iceberg. Remember, safety isn't just a good idea, it's the law.

4) Lung capacity is important

We all know that we have to breathe to live. It's shocking, then, that some workers don't choose to protect their lungs. On the wood flooring job site, there are several times when it is vital that contractors use respiratory protection, from simple disposable style respirators to full-face styles that have replaceable cartridges.

First, when sanding a floor, whether with a big machine, edger or buffer, it is important that protection against wood dust (widely recognized as a health hazard) be used. Secondly, respirators are recommended by almost all finish manufacturers. Use of an OSHA/NIOSH approved respirator is absolutely vital when working with certain types of finishes, such as conversion varnishes and moisture-cure finishes. Refer to the products' MSDS sheets for which respirator to use.

5) Seeing is important, too

It's cliché, but true: Accidents that could blind you can happen in the blink of an eye. When you are installing, sawing or even finishing, you need to protect them from high-speed projectiles and splashes. Options include safety glasses, goggles or a face shield, all of which offer impact resistant polycarbonate lenses. (Regular eye glasses do not qualify as safety glasses.) Goggles offer the advantage of sealing of the eye socket and distributing force more evenly if an impact does occur.

6) Hearing is vital

Huh? What was that? Unfortunately, there are many contractors walking around today who wish they would have used a little more common sense and a lot more hearing protection in their earlier years on the job site. You need to listen to your machines, especially sanders, to make sure they're running right, so protect your ears. Styles of hearing protection range from small, disposable foam cylinders to ear muffs, which resemble large headphones and seal off the entire ear from noise.

7) You need the restof your body, too

You know that guy who is partially deaf. Chances are he can't kneel either, because he spent a lifetime on the floor without knee pads. Happily, many contractors today are more aware of the damage that can be done. The best knee pads to use are contractor-grade pads with an outer material that won't damage or burnish the wood floor.

Don't forget your other parts that are at risk on the job site, either. Work boots protect your feet in case something heavy is dropped on top of them. One of the biggest hazards is working with saws and other power tools. Make it a practice to always unplug saws, routers and other tools before changing blades or making other adjustments. When using a table saw, use a push stick, not your fingers, near the blade. And be smart about where you position yourself when you're using that circular saw — you don't want it to kick back right into your lap. Also, never remove safety guards or other safety features on the tools — they're there fora reason.

8) Prevent fires

Unfortunately, there are several ways that wood flooring contractors can literally set their businesses on fire. The good news is that they are preventable with a little awareness of the hazards.

First, there's the danger of sanding bags and spontaneous combustion. Most of us have heard stories about contractors who have burned up either their shop, van, or (perhaps worst of all) someone's home because they left bags full of wood dust sitting around. This is easily preventable: Empty bags when they are about half full. Never leave a bag full of wood dust sitting around, even if you are just leaving for lunch. The risk simply isn't worth it.

Fire is also a possibility when staining. Stain-soaked rags are a major spontaneous combustion hazard. Never, ever leave them in the trash or even thrown together in a heap — the heat generated can cause them to ignite. Contractors deal with the rags in a variety of ways, from hanging them on a clothesline to spreading them out on a concrete floor to dry. The safest way is to seal them in a fireproof container with a tight-fitting lid. (Safety equipment suppliers make containers for just this purpose.)

Use caution in the finishing step, also. Most finish manufacturers recommend turning off all ignition sources and pilot lights in a house before finishing, especially with finishes that have a low flash point (such as moisture-cure finish). Contractors have been literally blown out of homes when a freshly finished floor ignited.

9) Protect the kids

If you don't practice safety for yourself, at least think of others around you. Especially when you're on a remodel job, there may be children present. When you leave for lunch, they'd love to try out your pneumatic nailer or give that edger a spin — that's why it's imperative that you disconnect all tools when they will be left unattended.

10) Quality=Money

That's the bottom line. Safe employees produce quality work, and that's what makes your business thrive.