Wood floor pro James Harbour of Harbour Precision Floors in North Wilkesboro, N.C., has seen a lot in his career as a wood floor pro, but he’d never seen a floor like this before. The wood flooring in the first three rooms of the home, built in the early 1970s by Leonard G. Herring, who was part of the management team that built the Lowe’s Companies, had flooring with strip pieces 1¾-inch wide, but throughout the floor they had been assembled into short sections where up to three rows were aligned, and some ends had pegs of the same species.

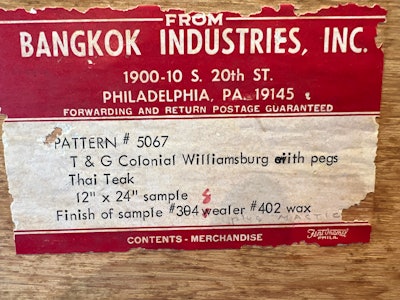

Harbour was perplexed. “Normally you’d want the joints to stagger,” he says. And looking at the wood, with its original finish still intact, he didn’t recognize the species. “I was texting everybody I knew, and Daniel Boone said it was teak.” The homeowner, who had purchased the home, then found a sample, confirming it was, indeed, teak. The sample said it was a “Thai Teak” product from a Philadelphia-based company called Bangkok Industries Inc. in a “T & G Colonial Williamsburg” pattern with sealer and wax.

At first Harbour thought it was glued to concrete, because most of the house is on a concrete slab. But then he realized the teak floors were over a crawl space, and the floor had been screwed down with the pegs.

The floor still had its original wax finish. “I started sanding with the big machine with 60-grit because it was soft, and I wanted to see what it would do,” Harbour explains. “I didn’t want to take a lot of the wood off for the life of the flooring, so I finessed it—I gently edged it and finished with 80-grit on the big machine.” Then he buffed with 100, 120 and 150 using the multi-head HydraSand on the Epoch with weights “because with all those short boards it’s difficult to achieve a flat-looking floor,” he adds.

“It’s one of the easiest floors I’ve ever sanded; it reminds me of walnut,” Harbour says. Although it was sticky, it was “nowhere near as bad as pine,” he says, adding that the dust in his vacuum cleaner was “fluffy,” not powdery like oak sawdust would be.

With the waterborne finish coats applied, the floor looked beautiful and was a drastic improvement over the aged wax finish, Harbour says: "The homeowners love the floor; she loves the natural look a lot better than the stain and wax."

SUPPLIERS: Abrasive: Norton, 3M | Big machine: American Sanders Legend | Buffer: American Sanders Epoch with HydraSand | Edger: American Sanders | Finish: Loba Easy Prime and 2K Duo Satin | Palm sander: Festool