Being able to rebuild staircases in addition to doing the wood floors helps my company land jobs.

Being able to rebuild staircases in addition to doing the wood floors helps my company land jobs.

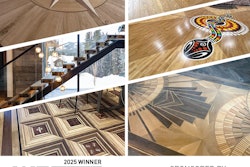

I've always loved tools and machinery. And I'll admit it: If I see something new and innovative, I want it, no matter what the cost. This goes for sanding machines (some people might say I have two or three more big machines than I really need), and vacuums (I have an infatuation with vacuums—it's normal to have more than 20, right?), and orbital sanders (you might call my collection a sort of "evolution" of orbital sanders), and more. I seem to be spending more than ever on tools, but recently my tool purchases have actually been part of my business's growth plan to keep creating a niche for my business. In the last five years or so, Totallywood has evolved from being a more typical wood flooring contracting business to also doing complete staircase rebuilds.

I've found that almost all hardwood flooring contractors don't like doing staircases. I often hear excuses like, "They are too difficult" or, "They take too much time." Just the other day another wood flooring contractor messaged me for advice on some stairs he was working on. He told me how much he hates stairs, and that he regretted bidding them. "How much do you charge?" he asked.

I certainly didn't set out to specialize in stairs, and I don't have any special training in them, but over the years, I started to get more comfortable working on them little by little. Maybe I'd be sanding some railings, for example, and think, "This isn't really that fun. It would be easier if I didn't have these balusters in the way." So, we started to remove them to make it easier. As I did more work on the stairs and removed a newel here or a nosing there, I learned how the staircase was fastened together. Being able to dismantle the parts and work on them individually makes it much easier to refinish them.

As I've gotten more comfortable with the stairs, it's become a niche skill for us, and customers love it. We seem to close a higher percentage of bids because we do the floor and the stairs—other contractors usually don't want to do them. It's been lucrative for us, and typically I won't turn any staircase work away. It helps to keep us busy.

These days, many times we'll take as much of the staircase apart as we can (treads and risers usually stay in place), and I'll send the parts to a furniture refinishing guy who will dip the parts to strip them. The stair parts come back raw, and then we just do a light sanding on them to prepare for staining. Next we reinstall all the parts except the balusters, and plug any holes used to hide fasteners and finish. It was intimidating at first: What if I break one of the parts? But now I'm confident, knowing that if something does break, I can fix it or make a new piece.

Now that I'm more comfortable working on staircases, I've realized many times it's just easier to replace most of the parts anyway instead of paying to send the old parts out to be stripped. That isn't intimidating to me anymore. Finding a quality supplier who offers fair pricing and good service is key. A lot of these staircases use standard parts, but most times the homeowners are receptive to when I upsell them to a new look, especially boxed newels and iron balusters. Iron has been huge for us! Replacing these parts can modernize the staircase to something that's better quality, looks amazing and is also easier for us to do.

RELATED: Step by Step: How to Install Wood Treads & Risers for Boxed-In Stairs

If I can't source the parts easily (you won't find a premade curved Brazilian cherry railing anywhere), or if the homeowner wants something fully custom, that brings us back to my point at the beginning of this article: Now I'm ready to manufacture the parts I need. We've evolved so that now instead of working out of my garage, I have a shop. That means I have room for a shaper ... and a planer … and a big band saw. They were a big investment, and like all tools and techniques, there is a lot to learn about them, but I'm starting to get to a place where I am able to do whatever I need and make custom parts. If the customer doesn't want a standard newel, I can say, "We can do it this way, or we can do it out of this species of wood." In my never-ending quest to have every tool out there, I'm starting to look into CNC machines, too. That type of technology is truly amazing and will maybe someday be obtainable for us.

These days, I genuinely enjoy doing stairs. They are challenging and rewarding, and it's been a learning experience. For me, it's true that "only installing strip flooring gets old quickly." This is a different part of my trade where I try to set myself apart while making money and being challenged. And, of course, the best part is buying the new tools I need to make it happen.