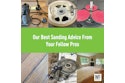

These cutters help us save money on abrasives.

These cutters help us save money on abrasives.

I love our favorite high-performance (and very expensive) rough-grit paper, but wanted to get more out of it. Voilá! I came up with a sandpaper recycling station. The middles of used discs are often still in excellent shape, and used 40-, 60-, and 80-grit belts usually still pack a punch when cut into discs. Here's how I make the most of our abrasives.

What I reuse

I'm careful about what I reuse. I throw away used 100- and 120-grit belts and discs, all 5-inch discs and smaller pieces. I use only new paper for final sanding, where quality counts the most. It's the "least expensive" paper, anyhow. The used coarser belts can be cut for edger paper. As discs, they usually have a lot of cutting power left (of course, they have no Velcro and must be bolted on). Used Velcro-backed discs can be cut into discs at least 2 inches smaller in diameter, as usually the centers are still very sharp.

What I use to cut abrasives

You can buy the three big disc cutters pictured from US Sander (I've found no other supplier at all on the internet, zero, nobody else), replacement blades, and 5/16- and ⅞-inch outbevel punch tubes for holes.

I made the smaller cutters with 3/4-inch plywood, sections cut from 7-inch cutter replacement blades, and large hose clamps. (A first aid kit may come in handy—ask me how I know.) Score the blades with a file, bend slightly back and forth with vise grips (Be safe! Wear gloves!), and snap the blades to length. Corralling the blades into the hose clamps takes some ingenuity; I used a V-shaped cut of scrap wood to help hold and shape the blade.

The homemade cutters work great when used on smooth concrete with a cheap rubber mallet (don't waste a flooring mallet). The small center-hole cutter that came with the 5-inch wasn't needed for my 5-inch disc uses, but it is the right size for vacuum holes on the smaller ones if needed—if you put a handle on it. I made a good handle in five minutes with scrap wood, a drill and a hot glue gun.

RELATED: Sanding 101: Wood Floor Sanding Basics

To make a triangle cutter, just trace the outline of your triangle paper on 3/4-inch plywood. Find something circular that is just big enough to cover it. Cut out the circle on a bandsaw or jigsaw. Then cut it apart on the triangle lines. I used masking tape on the wood triangle to measure (what I thought was) exactly how long the three blades would have to be. I took the tape off the wood, put it on the blade, scored the blade at my marks with a file, and broke the blade at the scores. I had to combine two big pipe clamps to reach around it all. Put the wood pieces back together, loosely put the pipe clamps on, slip the blades into the slots, and tighten. I had to grind one down a bit, and the other two were a smidge too short, but it works well on top of concrete. It hardly works at all on top of wood, because the back of the blades bury into the wood.

Cut sandpaper from the back side—never try to cut it from the grit side. Usually, just scoring the backing and folding it to break the paper works. Commercially sold cutters work by using a rubber mallet to force the backing into a blade attached to a metal form.

If you must have the dust collection holes, trace them on the back of the cut recycled paper and use the paddle-mounted punch, a block of wood, and a normal hammer to punch them. Often when you are using really coarse paper they aren't needed.

Some final tips

We have several crews going all the time, so the sandpaper cutters and rubber mallet sit in a box on the shelf of our warehouse. On the job, use recycled discs before using new discs. You will quickly learn what used paper to save and what to toss. Also, save some whole dull-but-clean 40-grit discs to use for cleaning up gummy finishes—there's no point in wasting expensive new paper on those.

Remember, sandpaper is expensive (especially the lower the grit number). If we can be smart and save money on paper, we will all benefit.

See the author demonstrate his tricks in action in this video:

RELATED: Your Sanding Machines Don't Look Like This, Do They?