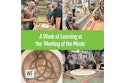

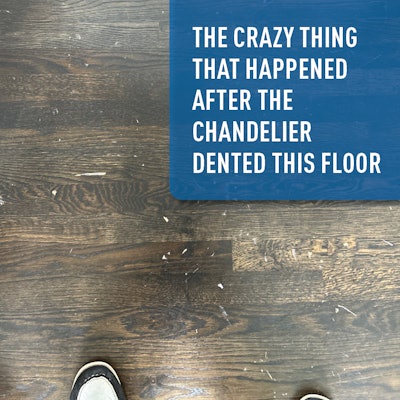

We had a really interesting thing just hit on a job—something I had never seen before. We were hired to do repairs on an oak strip floor after a 400-pound crystal chandelier in a foyer smashed onto the floor and crystals splattered everywhere. The floor was full of dents, as you see here:

We put in a bid to repair the floor, doing board replacements where necessary and then sanding, staining and coating the floor with waterborne finish to match the rest of the flooring. At first when we were on the job, I was thinking we needed to replace the boards with the dents. But one of my guys said, “Wait, let me try to sand it out.” Then he showed me the floor after sanding, and the dents were all gone. In my head, I was thinking, “We should have just replaced those boards.” But I told him, “You’re right, they sanded out, so let’s just keep going.”

We stained the floor and applied our three coats of waterborne finish, and the floor looked great. Then about a week later, we got a call from the customer saying that they could see all the dents. What? So I go there and look at it, and I’m not seeing dents. What I am seeing is a raised part of the floor where the dents were. Everywhere there was a dent, the grain raised. The grain had been compressed, and when we applied our three coats of waterborne finish, the grain uncompressed!

It was really hard to get a good photo of the raised areas; they looked more like boogers in the finish:

But if you tried to scrape them like you would doing a finish repair, you would hit a little mound of wood. I had to dig each one out—there were at least 30 of them—and then use my wax wood floor repair kit on each one to disguise all the repairs. If that hadn’t worked, of course we would have had to resand the entire floor and start over.

Knowing what I know now, if I were doing another job like this with waterborne finish, I would pre-water-pop the floor before sanding, but honestly, on this job I never thought about this situation happening in a million years.