We met Greg McGavran and James Berault from Vision Wood, based out of New Orleans. They had shipped some of their wood products in advance for us to see. It was the first times I’ve ever seen wood flooring that is 18-inch-wide engineered white oak laminated to a rift and quartered red and white oak substrate.

Greg explained to us some of the differences in how wood is graded in the U.S. versus Europe. We learned that Europeans don’t consider knots a "defect" because they don’t want to cut the wood and have smaller lengths. They actually consider sapwood a defect, though, and they mill and grade the wood to have consistent color that is free of sap wood.

It was very interesting to hear about Greg’s background in the wood flooring industry. One of the things he discussed that a lot of us didn’t know was how exotic wood floors received their American names.

Greg was one of the first to import ipé, cumaru and Jatoba wood flooring to the U.S. He said at first, it didn’t sell very well and was sitting in his inventory for quite some time. As a marketing strategy, he decided to rename the wood Brazilian walnut, Brazilian teak And Brazilian cherry. We all thought that was very interesting, and it was cool to meet the person that came up with the names most Americans use for these exotic woods.

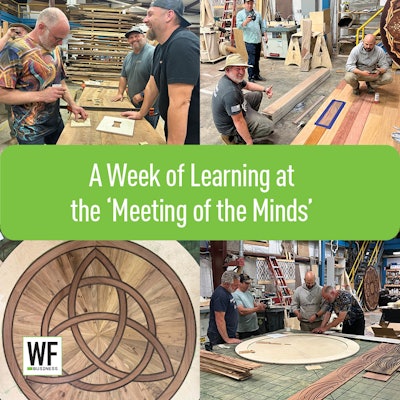

It this photo (left to right), Joshua Crossman, Dustin Bolin and Aaron Schaalma and are testing some reactives that Daniel Antes and Paul Golenya suggested to try on these exotic wood floors:

Here Jon Stedge of Distinctive Hardwood Floors is inspecting some bowtie inlays he made with the CNC machine to join together some walnut slabs for Daniel’s new desk:

Justin Boone built this beautiful live edge walnut desk for Daniel’s office. He joined the slabs together using bowties and dowels.

Dustin Bolin made a step stool for his kids out of some walnut scraps left over from Daniel’s desk:

We got to try out many of the machines in Dan's shop:

A morning meeting was held to discuss fabricating an inlay for one of Daniel’s customers:

Jon inspecting some of the pieces for the inlay:

Daniel giving us some tips on how to assemble the medallion:

The finished product:

Paul Golenya teaching us the correct application method of Odie’s Oil in Daniel’s new office:

I was able to demonstrate how to apply Wearmax Universal Armor ceramic bead finish multiple application methods: