Brochure cover from National Wood Flooring Association 1988 convention in Kansas City, Mo.

Brochure cover from National Wood Flooring Association 1988 convention in Kansas City, Mo.

One of the advantages of the waterborne finishes was, and still is, the benefit to the work and natural environment. Some manufacturers took umbrage at having a government agency telling them to focus on better air quality and fix their product when they didn’t consider their product broken. I vividly remember an executive with a well-known manufacturer getting into a shouting match with some poor patsy from the EPA at the Kansas City event. It made for some interesting theater, but contractors were looking beyond the drama. Applying a finish without noxious vapors had some very strong appeal, and it got the attention of a lot in the crowd, myself included.

The launch of waterborne finishes wasn’t without problems. There were issues that needed to be dealt with, and, to their credit, the manufacturers addressed them and now provide us with stable and high-performing products.

But the “game changer” aspect of waterborne finishes has been the aftershock: the influence of the product to institute changes the industry desperately needed to move forward. Here’s a list of the most obvious spinoffs:

- Dust containment: Waterborne finishes suffered more from contact with dust than solvent-based products. Simply put, they needed a cleaner work environment. When you look back at the evolution of dust containment in our business, you see waterborne manufactures in the lead.

- Improvements in stains: Oil-based stains often took too long to dry and this wreaked havoc. The solution was the introduction of faster and quicker drying stains that have proven to be more compatible with waterborne finishes and a huge time saver on a project.

- Inner coat abrasion: When screening between coats proved to be problematic, the synthetic maroon pads and fine sanding discs made their way onto the job site. This “kinder and gentler” approach has helped many contractors manage the finish phase without undue damage to a new, or old, finish.

- Application techniques: T-bars, foam applicators, cut-in pads and some large brushes all owe their existence to waterborne. Once the new finishes hit the market, it was clear you had to have some quicker way of getting these fast-drying products on the floor.

- Recoating: Waterborne owns this turf, and for good reason. Until they focused on it, the approach was haphazard and primitive at best. Better products for surface preparation and additives to enhance adhesion came from waterborne manufacturers.

- Maintenance products: Here again, the waterborne community jumped on this and moved it to the forefront. Today’s products are good, available and easily purchased. The sooner we educate the consumer on proper floor cleaning and maintenance, the quicker we reduce trouble and damage.

- Education & training: The waterborne crowd knew they had increased the learning curve for coatings applications and were proactive. Training schools addressed these challenges and eventually took the classes on the road. This represented a significant milestone.

- Accelerating job times: The rapid drying and curing time of the finishes and quick-drying stains have done more to reduce the time needed for refinishing work than any single event. The shorter curing time is very appealing to homeowners wanting to get on with their lifestyle.

- From worst to first: Finally, the trade that was considered the dirtiest, smelliest and chemically most hazardous has moved to the head of the class. No other building trade out there has done such a dramatic turnaround and now offers so many environmentally friendly options.

Looking back on the progress the wood flooring trade has made since Kansas City in 1988, I sometimes have to pinch myself. A building trade that barely had a pulse 20 years before turned a corner and got to the 21st century long before a lot of other trades. What happened at Kansas City was a big deal, a very big deal. It gave this industry traction. It was a game changer.

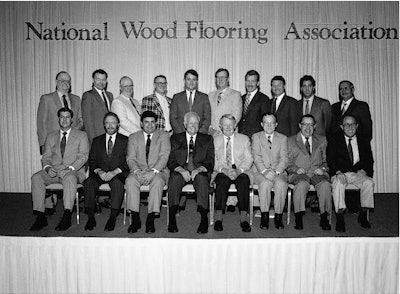

The board of directors of the National Wood Flooring Association at the NWFA convention in Kansas City, Mo., in 1988.

The board of directors of the National Wood Flooring Association at the NWFA convention in Kansas City, Mo., in 1988.