When you’re working on a wood flooring job, how do you know what type of safety equipment you should use? Or do you, like a lot of workers, not use any Personal Protective Equipment (PPE) at all? I know it’s not that you don’t care about your health and safety, but maybe you think there isn’t a real hazard associated with the job you’re doing. There are many common myths and misconceptions about PPE, and I’d like to set the record straight. Let’s look at some misguided beliefs for the most common safety products in the wood flooring industry: respirators, hearing protection and safety glasses.

|

Did you know?You are not allowed to have facial hair when wearing a respirator, as it can interfere with the seal of the mask. However, mustaches can be fine as long as it fits inside the seal of the respirator. |

Realities for respirators

You know wood dust can be a health hazard in the wood flooring industry, but did you know even if your airborne wood dust concentrations are well within OSHA’s Permissible Exposure Limit for nuisance dust, it is still wise to protect yourself? Both your skin and respiratory system can become sensitized to wood dust, meaning you can suffer severe allergic reactions after repeated exposures to lower concentrations of wood dust. In addition, wood dust can be an irritant to your eyes, respiratory system and skin, so wearing respiratory protection can help reduce some of those allergy-type symptoms.

But you have a “dustless” system, you say? Think those dustless systems are 100 percent dust-free? Think again. Although they greatly reduce the amount of wood dust, there will still be some very fine wood particles getting kicked up and lingering in the air that you’ll be breathing in, even if you can’t see it.

Also, when it’s time to empty the dust bag, just because the sander’s turned off doesn’t mean you can now take off the respirator! When you open up that top and pull out the bag, you kick up a ton of wood dust that was contained inside, causing basically a plume of wood particles in high concentrations. Just another great reason to wear a respirator. So, how do you choose and know what respirator to wear? It’s important to know some facts:

Dust masks are not the same as respirators. There’s a common misconception that all “masks” are the same. In fact, a mask is not the same as a respirator. Did you know respirators used in a workplace must be tested and approved to National Institute for Occupational Safety and Health (NIOSH) standards? NIOSH approvals are given to disposable respiratory protection devices that help reduce exposure to particulate hazards. Though comfort masks may look similar to a filtering facepiece respirator, they don’t have NIOSH approval because the material they are made of is not capable of filtering out the fine dust particles that can enter your lungs and cause irritation.

For wood flooring work, disposable N95 cup-style respirators are the most common. They help protect you from solid particulates in the air, such as wood dust from a floor sander, and are also good for liquid particulates (mists and sprays). They are inexpensive, lightweight and comfortable to wear for longer periods of time.

You need medical clearance to wear a respirator. Contrary to what you may think, you can’t just throw on an N95 respirator and start working. You first need medical clearance to ensure you are healthy and fit enough to wear the respirator. You also need to be fit-tested to the specific respirator model that you need for the job at hand. This is necessary to ensure the respirator you wear forms a tight seal around your face.

RELATED: Safety Lessons from Real Wood Flooring Contractors

The seal is critical. It’s a common belief that simply wearing a respirator will help protect you, but in reality, the seal between the respirator and your face is the most important factor in protecting your lungs. There’s a specific protocol on how to properly put on a respirator and check the seal. It is important to follow the manufacturer’s user instructions that come with your respirator to ensure you are using the product correctly.

Reusables don’t guarantee a better seal. Many people assume that because a reusable respirator has a rubber-like facepiece, it will form a better seal to the face and offer more protection than a disposable respirator. The truth is, when properly fit, a disposable respirator can offer the same level of protection as a reusable respirator. Just as with disposables, you must be medically cleared and fit-tested for reusable respirators.

Not all reusable cartridges are the same. If you’re stripping old finishes or applying new ones, a half- or full-facepiece reusable respirator with appropriate chemical cartridges is better suited for the job than a disposable one. One myth about reusable respirators is that any carbon cartridge will work for chemical exposures. In reality, you need to match the chemical cartridge to the chemicals in the product you are using. Cartridges are NIOSH-approved to help reduce exposure to specific chemicals, so look on the packaging for which chemicals the cartridges are meant to help protect against.

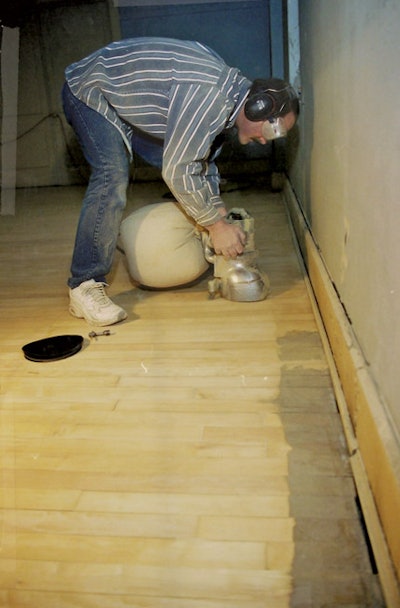

It's best to always use safety equipment, even if you think you might not need it for that task. Here, a respirator would complete the arsenal of protection.

It's best to always use safety equipment, even if you think you might not need it for that task. Here, a respirator would complete the arsenal of protection.

Know the hazardous chemicals in our industry. In the wood flooring industry, there are certain chemicals that are particularly dangerous. For example, keep an eye out for methylene chloride when working with strippers. Cartridges are not effective at filtering it out. This is also true for methanol, which can sometimes be found in certain finishes. If you are exposed to either of these chemicals in concentrations that exceed OSHA’s limits, you need to use a supplied air system to help protect your lungs. There are many other dangerous chemicals out there, so do your homework before starting a job with unfamiliar products.

Watch out for lead and asbestos. When removing or sanding old wood floors, you may encounter lead and asbestos. Asbestos is usually best left undisturbed; if you suspect asbestos in old flooring and it must be removed, ask the homeowner to have it tested and, if necessary, removed by an asbestos remediation company. When working on homes built before 1978, remember that you must comply with the requirements of the EPA’s Lead Paint Renovation, Repair and Painting Rule. Lead is a serious health hazard that requires an N100 or P100 particulate filter. For this type of work, a full-facepiece respirator is often preferred to protect the eyes and face. A coverall should also be a part of the PPE ensemble. It’s commonly believed that coveralls are solely used to keep your own clothes free of debris and grime, but a coverall is really used to contain the hazardous particulates. This is done by preventing hazardous particulates from clinging to your skin or clothing, allowing you to potentially transfer those hazards outside of the containment area and contaminate other areas.

Beware of facial hair affecting fit. A proper fit is needed for both a reusable and disposable respirator, and you know what can affect a proper fit? Facial hair. No matter if it’s a disposable or reusable respirator, you need to be clean-shaven. You may think a 5 o’clock shadow is just fine, but let me assure you, when it comes to respirators, it is not. Even a day’s growth of stubble is enough to interfere with the seal to the face.

|

Did you know?Once hearing is damaged, it does not heal itself like other injuries—it's permanent. |

Sound advice for hearing protection

Most people don’t automatically realize when they should protect their hearing. For one, they don’t think about their hearing becoming damaged. Unlike other injuries, it’s hard to imagine your hearing becoming “injured.” But, when exposed to loud noises over time, your hearing will deteriorate until you have permanent hearing loss. Because this can happen slowly over time, most people don’t realize their hearing is being damaged until it’s too late. Here are some hearing facts to keep in mind:

Hearing can be damaged long before sounds are painful. Some people believe they only need hearing protection if the noise is so loud it becomes painful to listen to. Although damage can definitely occur when the sound level is that loud, damage can occur much sooner than that. So, when do you need hearing protection? A good rule of thumb is to use hearing protection for noise louder than 85 decibels. To get an idea of how loud that is, anytime you have to speak loudly or shout to someone 3 feet away so they can hear you, it is too loud and you should protect your hearing.

In the flooring industry, big machines and edgers and even pneumatic nailers can get pretty loud. Did you know big machines can get into the upper 90s on the decibel scale? According to NIOSH, you are only permitted 30 minutes of exposure at 97 decibels before you need to wear hearing protection. And most workers will be using a big machine for much longer than that. Edgers can get even louder, which means you will need hearing protection even sooner.

And those pneumatic nailers? You better believe those things can damage your hearing over time. Pounding away on one while installing the flooring is almost like being at a gun range. Do yourself a favor and wear some earplugs or an earmuff when using the nailer.

Even a short duration of noise can damage your hearing. Another common mistake is thinking a short duration of loud noise exposure won’t do any harm. You may think you don’t need hearing protection when using that chop saw or circular saw because it takes only a few seconds to make a cut, but even short-duration exposures can damage your hearing because…

Repeated exposures add up. Remember, if you’re being exposed to loud noises without hearing protection day-after-day for many weeks, months or years, you will sustain hearing damage. And once your hearing is damaged, it is permanent and does not come back.

Getting the proper fit with hearing protection is essential for ensuring your safety. An improper fit can greatly reduce the amount of noise reduction the product can provide. For example, people commonly assume simply placing an earplug in their ear will provide adequate protection. In reality, earplugs need to be placed much deeper in the ear canal than most realize to get a proper fit. How do you know if the earplugs are deep enough? Once you have them in, try cupping your hands over your ears. If you hear a drop in the ambient noise around you, it means the earplugs weren’t fit properly and you need to refit them. If the ambient noise level stays the same, it‘s an indication you have a good fit.

Earplugs and earmuffs both provide good protection. If you can’t find an earplug that fits comfortably in your ear canal, consider an earmuff instead. There’s a myth that earmuffs provide more protection than earplugs because they’re larger and fit over your ears. This just isn’t true. The NRR (Noise Reduction Rating) is the best indication of how much protection an earplug or earmuff can potentially give you. Look at the packaging to see what the NRR is for the product. Generally speaking, the higher the NRR, the higher the protection.

Earmuff fit is important. Fit is just as important for an earmuff as it is for an earplug. To ensure a proper, firm fit, make sure there is no gap between the band of the earmuff and your head. This allows the headband to “pull” the cups against your head properly. If the cups don’t press against your head firmly, you may not have the level of protection the earmuff is rated for.

|

Did you know?Safety glasses are typically tested to certain safety standards. In the U.S., look on the packaging for “ANSI Z87.” This tells you the glasses have passed the American National Standard Institute’s test methods for safety eyewear. |

Safety in sight

Every day approximately 2,000 U.S. workers sustain a work-related eye injury that requires medical treatment. Most of those accidents are completely avoidable. Here are some things to know to preserve your sight:

Wear them even if you think you don’t need them. Eye injuries occur for two main reasons, and one is when workers think they simply don’t need safety glasses for certain jobs. Even if you’re sanding a wood floor, dust and debris can get kicked up. If you’re installing a wood floor, you’ll likely be using a pneumatic nailer, and one slip or mistake could cause a permanent eye injury.

Today’s safety glasses are comfortable. Another main reason you might avoid safety glasses is because you think they are uncomfortable. That may have been the case years ago, but not now. Safety glasses have come a long way since the large, clunky science-class safety glasses from grade school. There are many more choices available now, with features like rubber nosepieces that decrease pinching and slipping. Some also feature rubber on the temples for a better and more comfortable fit. If you’re one of those people who believe all safety glasses fog up, remember to look for a pair of glasses with an anti-fog coating.

Safety glasses don’t have to be ugly. Many safety glasses also offer nice wraparound styles that provide broad coverage around the eyes. Safety glasses design has come a long way, too, so you don’t have to worry about looking like you did in science class anymore.

Take the time to find the right fit. You may not find a pair that fits you perfectly right away, but keep looking. For your comfort and safety, finding the right pair will be worth it in the end. Remember, it only takes a split second for something to happen and cause a permanent eye injury. And since your sight is so valuable, why risk it? Always wear your safety glasses.

Now that I’ve debunked some common myths and misconceptions about safety products, you should be out of excuses for not protecting yourself on the job. Get out there, and keep yourself and your workers safe! π