In the majority of cases, we know that one walks on the finish on wood floors, not on the bare wood, and that by practicing good maintenance procedures, the finish should last for years. Over time, though, all finishes will need some love, and, potentially, recoating. Recoating can be challenging, to say the least. Frankly, it can be a total crap shoot unless you know what is on the floor in advance or you know how to determine what coating is on the floor. Knowledge is power! There are millions of square feet of wood floors out there that will eventually need to either be recoated, sanded and finished or ripped up. By educating yourself, a huge market opens up. Here are some steps and tips that can help you be successful when pursuing this lucrative market.

Find out what you’re working with

You wouldn’t coat a waxed floor with a urethane finish—it would peel like a tourist on Miami Beach who spent too much time in the sun! This is true across the board (pun intended); you have to find out what you are working with. There are more horror stories out there than even Stephen King could imagine! Think about this: You took on a simple buff and coat, did the work and the client is not happy. You attempt a do-over. Still no happy campers in sight. You come to the conclusion that you bit off more than you can chew and aren’t going to get paid. But wait, it gets worse: The homeowners hold you responsible for permanently damaging their floor and demand that you pay to have it removed and replaced. You start doing the math … 1,500 square feet x $$$$ ... You decide that maybe you should learn plumbing. It boils down to knowledge and keeping up with changing products and techniques in your trade. Oh, by the way, plumbers have their crappy issues, too.

1) Does it have acrylics and/or oil soaps?

The following apply to factory-finished floors or job-site-finished floors (besides penetrating oils—more on those later):

Test the coating first to make sure it hasn’t been “maintained” with a “refresher” acrylic or an oil soap. Ask a lot of questions, and don’t be afraid to ask the consumer to show you what they have been using to clean or maintain the floors. You will be surprised at what you will find. The best way to contend with oil soap, even if you are not positive it was used, is to deep-clean the floor with one of the more aggressive professional wood floor cleaners on the market (products such as Basic Coatings IFT, Bona Prep, etc.). To test for acrylic:

- Drip ammonia on the surface. Some products with acrylic in them will turn whitish, and the ammonia will soften the acrylic. Note that this is not a guarantee! Some acrylic products will not turn white. If you find or even suspect acrylic on the floor, there are a lot of products out there made to remove acrylic top coatings: Basic Coatings’ Dissolver, Bona Polish Remover, Floor Science Floor Stripper, Zep Floor Stripper, or you can use a homemade cleaner. Here is a process for a homemade cleaner that works to remove acrylic:

- Mix 1 gallon of white vinegar with 1 cup of cream of tartar. Make sure the tartar is completely dissolved in the vinegar.

- Mop the floor with the mixture.

- Rinse and dry the floor with clean rags.

- Mix 2 gallons of hot water with 2 cups of ammonia and 1 cup of powdered dishwashing detergent.

- Scrub the floor with a buffer and a red pad.

- Rinse.

- Clean again with the white vinegar and tartar mixture.

“Refresher” type of products like these are commonplace and can cause finish adhesion problems when recoating, so they must be detected and removed before a new coat of finish.

“Refresher” type of products like these are commonplace and can cause finish adhesion problems when recoating, so they must be detected and removed before a new coat of finish.

A few drops of ammonia on a wood floor in an inconspicuous place can sometimes reveal if the wood floor finish is contaminated with an acrylic “refresher” type of product—the spot will turn white, as you can see in the photo above.

A few drops of ammonia on a wood floor in an inconspicuous place can sometimes reveal if the wood floor finish is contaminated with an acrylic “refresher” type of product—the spot will turn white, as you can see in the photo above.

TIP: Before you recoat, always clean!!!

Once you know what’s on (or not on) the floor, before you think about recoating the floor, you have to clean the floor with the appropriate cleaning agent. Floors with oil and wax finishes have their own processes (see those sections in the article). For other finishes, clean aggressively using a buffer and red pad or an autoscrubber, if you have one. TSP (trisodium phosphate) is a robust cleaning option that removes grease, stubborn junk, and mildew from both painted and unpainted wood. After cleaning and buffing, do a test spot in a place where contamination would be likely to be present to ensure the finish you are going to use bonds before proceeding.

2) Is it aluminum-oxide or ceramic-coated factory-finished?

Factory-finished floors with UV-cured urethane may contain minerals like aluminum oxide or ceramic to make the floors more scratch-resistant, and these minerals can make recoating much more work. If you encounter one of these floors, you need to know what it is ahead of time so you can plan for the extra time and expense, and have the right abrasives, too. Aluminum oxide is the most common, but there are also wood floors with ceramic in the coating. If you suspect you’re dealing with one of these floors, here’s how to test for them:

- Using a permanent marker in an inconspicuous spot, make a mark on the finish and wipe it up right away with a clean rag. If the coating contains aluminum oxide, the marker will leave a shadow. If it is ceramic, it will wipe off cleanly.

- Abrade a small inconspicuous area with a true ceramic or diamond abrasive; use a 180 or 220 grit. If the finish powders, you may continue by buffing the floor with either a ceramic screen or equal, or ceramic paper placed on a maroon pad, or multi-disc. This process leaves micro scratches that provide a mechanical bond between the old coating and the new.

- If the permanent marker test shows the finish to contain ceramic, use a chemical bonding system (like Bona Prep or Basic Coatings’ TyKote) after cleaning the floor.

UV-cured urethane without aluminum oxide or ceramic will powder easily when abraded with a ceramic or diamond abrasive.

UV-cured urethane without aluminum oxide or ceramic will powder easily when abraded with a ceramic or diamond abrasive.

The Sharpie test (in an inconspicuous spot!) is helpful for determining which type of finish is on the floor. If the Sharpie will not come off with a clean rag or paper towel, the finish is not ceramic (this floor is aluminum oxide). If the finish had ceramic, the mark would wipe off.

The Sharpie test (in an inconspicuous spot!) is helpful for determining which type of finish is on the floor. If the Sharpie will not come off with a clean rag or paper towel, the finish is not ceramic (this floor is aluminum oxide). If the finish had ceramic, the mark would wipe off.

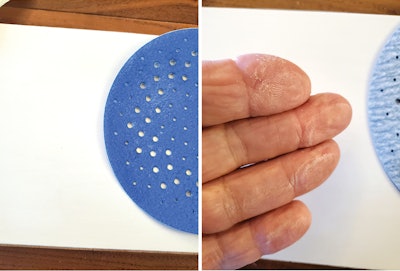

In these two photos above we have an aluminum-oxide-coated prefinished floor, which will powder when you abrade it with a ceramic or diamond abrasive.

In these two photos above we have an aluminum-oxide-coated prefinished floor, which will powder when you abrade it with a ceramic or diamond abrasive.

3) Has it been waxed?

If you think it’s possible the floor has been waxed, there are a couple ways to test for it:

- Drip alcohol on the floor (again, in an inconspicuous place). The wax will turn whitish if the alcohol is left on the floor.

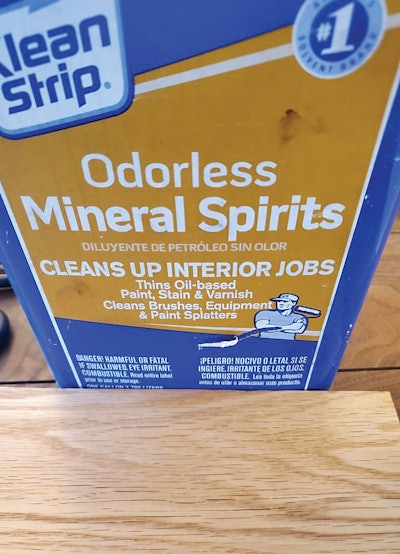

- Another way to check for wax is by wetting a rag with mineral spirits, then wiping the floor. If the floor is coated with paste wax, the wax will come off on the rag (usually a yellowish color).

If you find the floor has wax, know that waxed floors must be recoated with wax. When wood is waxed, the buffing process drives the wax deep into the grain of the wood and between the side-match and end-match of the boards. It is always safer to rewax. The process is pretty straightforward.

First, thoroughly vacuum the floor and tack it with mineral spirits to make sure you don’t scratch it on the next step.

Using a buffer with a pad driver and either steel wool (000) or a red pad, buff the floor with a product like DuraSeal Renovator or mineral spirits. Keep changing the pads until the floor is clean and no heavy wax residue is left on the pads.

Apply either paste wax or liquid wax. Paste wax must be applied just like waxing a car. Apply a thin uniform coat, then using a thick white polishing pad or lambswool buffer bonnet, buff until the floor has a uniform low luster. With liquid wax, you may use a lambswool applicator or pour the wax on the floor and buff it to a low luster. Make samples so your client knows what to expect.

Here’s a waxing trick of the trade: Fill a white cotton sock with paste wax, tie the open end and use it to apply the wax. The natural holes in the cotton coupled with the heat of application will meter the wax beautifully.

If the client wants a film-build coating, the floor must be sanded to bare wood and finished. Even if you do sand to bare wood, know that there may be spot adhesion issues or discoloration (especially in the deeper open-grain areas and side and end joints). The bottom line is you don’t get paid until you fix the floor. Err on the side of rewaxing, or simply turn down the job.

This floor is waxed, but there’s no way to just look at it and tell—to know for sure, there are a couple simple techniques.

This floor is waxed, but there’s no way to just look at it and tell—to know for sure, there are a couple simple techniques.

One way to test for wax is to use mineral spirits on a clean white rag or paper towel and rub the floor with it. If it has wax, some wax will come off on the white rag or paper towel, as seen below.

One way to test for wax is to use mineral spirits on a clean white rag or paper towel and rub the floor with it. If it has wax, some wax will come off on the white rag or paper towel, as seen below.

As seen above, wax will turn white when liquids are allowed to sit on the floor, and you can use this to your advantage when testing for wax. Place a few drops of alcohol on the floor in an inconspicuous place and let them dry to see if the floor turns white (this could take 30 minutes or a couple hours). These white spots were incidental when an alcohol cleaner was accidentally spilled onto the floor.Photo courtesy of Daniel Boone

As seen above, wax will turn white when liquids are allowed to sit on the floor, and you can use this to your advantage when testing for wax. Place a few drops of alcohol on the floor in an inconspicuous place and let them dry to see if the floor turns white (this could take 30 minutes or a couple hours). These white spots were incidental when an alcohol cleaner was accidentally spilled onto the floor.Photo courtesy of Daniel Boone

This wax floor has been rewaxed every year for 17 years so far; here you can see wax has been applied and a buffer with a horsehair pad is about to go back over that area to work the wax into the floor.Photo courtesy of Daniel Boone

This wax floor has been rewaxed every year for 17 years so far; here you can see wax has been applied and a buffer with a horsehair pad is about to go back over that area to work the wax into the floor.Photo courtesy of Daniel Boone

4) Is it an oiled floor?

You also have to determine if the floor is coated with an oil (a hardwax oil, linseed oil, any type of oil)—this could apply to a job-site-finished floor or a factory-finished floor. Ask questions. For job-site-finished floors, try to find out which brand of finish was used, and for factory-finished flooring, try to find out the brand of flooring. If you aren’t sure if the floor has an oil finish, test it with a clean rag and lacquer thinner in an inconspicuous spot. If the floor is oiled, some oil will come off on the rag.

For recoating oiled floors, some clients may ask to have a coating that has a film build over the oil. To do this, clean the floor with a mild detergent recommended for oiled floors. Then buff with a fine abrasive pad and coat with the finish of your choice. I have coated over oiled floors with various brands of water-based and oil-modified urethane finishes with no problems over the past 20 years, but it’s always best to check with the manufacturer of the finish to CYA.

Recoating oiled floors is simpler than recoating film-building finishes, as oils are designed to be easy to repair and recoat. If you can find out what brand of oil was used, use the same cleaner and oil to recoat. If not, clean with an oil soap cleaner made for oils—all manufacturers of these products make a cleaner like this (do not use an off-the-shelf cleaner like Murphy’s oil soap!). Then apply the oil as you would normally.

When deep-cleaning before re-oiling, use the cleaning product recommended for that brand of oil.Photo courtesy of Jorge Perez

When deep-cleaning before re-oiling, use the cleaning product recommended for that brand of oil.Photo courtesy of Jorge Perez

Oil-finished floors are designed to be easy to recoat.Photo courtesy of Travis Morse

Oil-finished floors are designed to be easy to recoat.Photo courtesy of Travis Morse

5) Is it shellac?

Experienced wood flooring pros may be able to tell a floor is shellac by the orange color and the look of the finish. Usually floors with shellac are topcoated with wax (in which case, you have to do the wax testing discussed on page 38). If the floor has only shellac, it may be recoated with more shellac or coated with a urethane (after cleaning the floor, of course). Shellac may also be waxed. Shellac is still used in woodworking, but not much in wood flooring with the exception of sealers. It is available in wax-free and shellac/wax. It gives wood a nice deep, rich color in the brown/yellow hues.

This floor has a sealer coat of shellac.Photo courtesy of Benny Powell

This floor has a sealer coat of shellac.Photo courtesy of Benny Powell