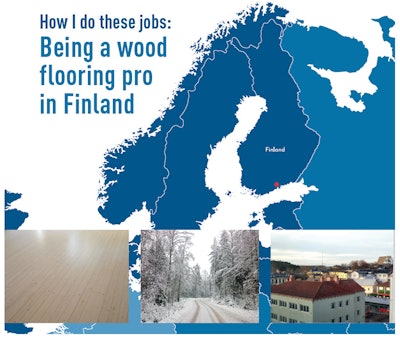

When I was young, school was my priority. My wood flooring pro father always told me to "stay in school and do something else that is an easier, thinking job," but when I was 14 he had me learn his trade as a skill to have in reserve. After I did my military service (here in Finland, service is mandatory—we share more than 1,000 kilometers of border with Russia), my father had an accident, and I took over the family company. We could have shut it down, but in our small area, we didn't want to lose the company name that customers had known since 1982.

Today, I'm age 37 and still running the company. One big way the industry has changed is in how connected wood flooring pros can be no matter where we are in the world. Although I'm on the southern coast of Finland, by being in Facebook groups made up of mostly North American wood flooring pros, I've observed many big differences in what is normal in the wood flooring industry here and in North America. Following are some of the main things I have noticed that are different about doing business as a wood flooring pro in Finland.

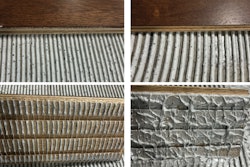

The majority of the wood flooring in Finland is solid tongue-and-groove spruce (above) or fingerblock parquet (below). We installed enormous amounts of fingerblock until that style ended in the '90s.

The majority of the wood flooring in Finland is solid tongue-and-groove spruce (above) or fingerblock parquet (below). We installed enormous amounts of fingerblock until that style ended in the '90s.

1) 99% of my business is sanding and finishing

The flooring business in Finland has gone to a kind of "post-hardwood" state in which construction is heavily standardized. In the name of speed and cost-effectiveness, new flooring projects have gone completely to engineered wood flooring, laminate or vinyl. They are fast to lay and are floated over concrete. Sports arenas and schools have gone completely to plastic flooring. There does seem to be a movement starting to favor real wood again, however, and if there is a lot of money involved in the building of a house, then wood it is. But most residential houses here are built for sale, so the end user does not have a chance to choose, and the flooring that is faster and cheaper wins.

In the 1970s and 1980s the standard here was to lay fingerblock parquet in every apartment and most residential houses. We installed huge amounts of that fingerblock, but that business dried up in the 1990s, so today we install only one fingerblock parquet job every couple years. Today 99% of my jobs are resands, mostly in private homes; they usually take place before new people move in.

Here in Finland, most flooring pros do not install plank-type wood floors at all; those are done by carpenters. Maybe once a year I have a customer ask if I could install one, but since I have no experience with it, I won't take those jobs (some floor guys are specialized in installing, but I'm not).

2) Spruce is most common

Solid tongue-and-groove spruce is the most common wood flooring here; nearly all pre-war houses and apartment buildings in the Helsinki area have it, and it is very common still today. When the floors are really old, the nails in the flooring are hand-made, and when even older, they didn't even have nails at all—they have wood pins. Because of all the spruce, softwood is most common for our sanding jobs. All of the summer houses, which are extremely popular here, have spruce flooring. Some of the spruce flooring here in Finland is as old as the United States! Typical dimensions for solid spruce flooring are 95 to 120 mm (3 3/4 to 4 3/4 inch) and a thickness of around 30 mm (1 1/5 inch). Some other species you might find here as plank flooring are pine and birch.

Unlike most wood flooring pros in Finland, I do have a regular work van, but I often use my Toyota Rav4 to get to summer houses (above) and to fit through narrow walkways in apartment buildings, like the one below in Helsinki. Bottom, you can see my sanding equipment is a tight squeeze in my Rav.

Unlike most wood flooring pros in Finland, I do have a regular work van, but I often use my Toyota Rav4 to get to summer houses (above) and to fit through narrow walkways in apartment buildings, like the one below in Helsinki. Bottom, you can see my sanding equipment is a tight squeeze in my Rav.

As I mentioned, fingerblock parquet is very common here, mostly in white oak but also some ash. It came with the huge apartment building boom that happened from the 1970s through the 1990s. In those days, throughout the country wood flooring pros installed a million square meters (more than 10.7 million square feet) of that fingerblock annually. (Today it is not even 10,000 square meters, or 107,639 square feet.) The dimensions for the fingerblock are 8 mm thick (3/10 inch) and lengths from 120 to 160 mm (approximately 4 3/4 to 6 3/10 inch) are possible (in the old days the factories used to have different dimensions).

After those two flooring types, the most common wood flooring I sand is engineered flooring with three layers.

We do have other species, such as cherry, maple and African woods, but they are rare.

A local specialty is heated floors; they are common and problematic since we have an extremely dry season during the winter and relatively high humidity in summer, particularly for the numerous homes near the lakes and the sea.

3) Jobs are small, and so are work vehicles

In general, the size of our projects here is small, around 35 square meters (about 377 square feet), but I have a minimum billing sum: 650 euros for clear and 750 euros for white. Normally I do not even go to see jobs before I do them because it takes too much time. Some jobs are good and some are bad, but generally they even out to average, so it works out. I get all my jobs over the phone; we go through basic details and agree on an exact day (most jobs take one to two days). It is common that I don't meet the customer in the morning—usually the key is hidden somewhere. In fact, many times I do not meet the customer face to face at all; I just leave the key in the same place when I am done and send the invoice after.

One thing I really hate in the houses here is having to sand behind water radiator pipes—almost all houses here have a water circulating system. Another quirk here is that the expectation is that customers remove and re-install their trim themselves.

I do have a real van, an Opel Vivaro (also known as the Nissan Primastar and Renault Trafic), but this is unusual in the flooring business in Finland. My other work vehicle is my Toyota RAV4, which I use to get to the summer houses, particularly when I need the 4x4, and is much more handy to park in Helsinki. It fits through many walkways, getting tools closer to the front door.

Above left, when I run my 220 sanding equipment, I can just plug it into the wall. Above right, all breaker boxes in Finland look like this; I always take a photo of it before I start the job so it's easy to see what I tripped.

Above left, when I run my 220 sanding equipment, I can just plug it into the wall. Above right, all breaker boxes in Finland look like this; I always take a photo of it before I start the job so it's easy to see what I tripped.

4) It can be cold and dark

In Finland all houses have a small vestibule to keep warm air separated from outside cold air and not let too much heat escape when you go out through the front door. It is also used for keeping shoes, since no one in Finland walks inside with shoes—people are even amazed when I carry in my big machine while wearing shoes. Because no one wears their shoes in the house here, all substances like sand and snow do not get into the house, so floors last longer. The vestibule also makes a handy place to keep tools and finishes, particularly when finish will freeze while left in the van (I've had finish freeze on the floor before, so conditions do vary!).

RELATED: Video: Thinking About Your Machines in Winter

Because we are so far north, we have very limited daylight in winter. I'm writing this in December, and we have a maximum of six hours of daylight right now, so work lights on the job are a must. (On a related cultural note, Finnish people do not do small talk. It is said that Finnish people would be ideal for travel to Mars because for us, it is totally natural to be in a small room with other people surrounded in everlasting darkness visible with only a small window for half a year and not speak for weeks!)

5) All houses have 220 power outlets

Every house here has sockets for 220 power, and the sockets by the washing machine, dryer and dish washer have heavier wire behind them and are under a 16-amp fuse, so those will run every machine you think of. Usually there are also three-phase 380-volt outlets next to the fuses or the garage. I have older machines, but any new 10-amp sander will run from any socket in all houses, and no one in the sanding business uses the three-phase option, they just plug in and go.

Breaker boxes here are very modern (see the photo above); I always take a picture of it before I start the job so if I trip one I can easily see which one tripped. The entire country has remotely readable electric consumption meters that are read using the mobile phone grid. The electric company can cut out the electricity remotely, which is sometimes an issue when you are doing work in houses that are empty and changing owners—sometimes the new owner will have a contract with a different electric supplier. However, this is easily fixed, as it can be turned back on in seconds. The government is forcing electric companies to make the grid more error-free, so all electric wires are now being dug into the ground.

6) White floors and waterborne finish

Before the year 2000 all floors were clear-coated, but since then white has become more and more popular, and now about 80 percent of my floors are colored white. The most common reason for resanding is that they want absolutely no yellow color and no dark, and they regularly ask to be sure the finish I'm using will not yellow over time. They want white—pure white, not even gray.

We changed to using water-based finishes in 1985, and I do not know any floor guy who uses anything other than water-based. With those finishes, yellowing is minimal, and that is what customers want. I honestly don't know if poly or acid-type lacquer are banned in Finland, but it does not matter, since no one will use anything that has a strong odor.

I have never stained a floor. When using color instead of natural, we use the same color that is used in paint mixers directly into the finish. I use Loba finish, and the Loba factory in Sweden even makes a product that has white mixed into it at the factory. However, I add even more color to it, because the white they prefer in Sweden is not enough for our local taste. We use no base coat at all—just three coats of finish with the color added, sanding between coats.

RELATED: How to Handle Tricky Wood Finishing Situations Like a Pro

An issue with this is you have only a couple of minutes to get the color rolled evenly and without mistakes. If the finish starts to dry and you have a double layer, then it's time to take out the sander and start over. It isn't an easy technique, but like everything, practice makes you better (never perfect). The color on the floor doesn't soak into the floor like it would with stain or an oil finish, but customers here would rather have the pure white color over anything that might yellow at all. A benefit of putting the color directly into the finish is that it behaves like a clear coat, not highlighting sanding mistakes like a stain would. Overall, this is a fast method, and maybe a little too fast for those trying it for the first time.

Maybe once or twice a year I will get a request for a dark brown or black floor, and I'll use an oil finish to get that color.

Summer houses are common here and many of my jobs are floors that are rarely used, so winter is downtime and is a good time for maintenance. We have a maximum of six hours of light in winter, so work lights are a must (this photo shows one of my jobs at 3:20 p.m.). This project had a dirt road with clear ice, and I nearly drove off the road. When finished, there was a red fox, a deer running in headlights and a huge moose walked by the road—all in that one trip.

Summer houses are common here and many of my jobs are floors that are rarely used, so winter is downtime and is a good time for maintenance. We have a maximum of six hours of light in winter, so work lights are a must (this photo shows one of my jobs at 3:20 p.m.). This project had a dirt road with clear ice, and I nearly drove off the road. When finished, there was a red fox, a deer running in headlights and a huge moose walked by the road—all in that one trip.

7) Money is handled almost completely electronically

When it comes to the flooring business, I was shocked to find out that cash or checks are used in North America. I asked my father about checks, which I had seen only in movies, never in real life, and he said he last saw one in the early '80s. In Finland when I complete the job I will send an invoice via email, through an e-invoice or with a paper invoice, and they have 14 days to pay it. E-invoice is widely used; you just upload your invoice to the website of the customer's bank and fill out all the necessary information. The bank tells them they have an invoice and the customer simply accepts it on the browser or in an app.

I realize that cash is becoming less common everywhere, but the most important reason for this cash-free system in Finland is that everything is monitored by the government so there are no "tax-free" jobs done. The government's tax department can check anyone's bank account at any time. Like they say in Finland, "The only things mandatory in life are to pay taxes and die." Also, having cash is more of an issue today, as banks don't work with cash and are only open three hours a day anyway. Actual cash is handled only through ATM machines.

8) I don't have to worry about having health insurance

We have national healthcare, and, simply, it is great. It is cost-effective, works great with the public sector and provides what people need—no one is left out. Yes, it is a little bit congested, but it prioritizes based on need. If you are in a hurry, you can go the private sector, but today the national system is considered better and worth the wait (the national sector will cover part of the private sector costs if you choose to do that). Dental care is included in the system.

Above you can see a tool used only in Finland; it's called the Flotex and it's a steel trowel with a type of flooring carpet glued to it. It leaves a very even coat, even while turning, and is a very fast tool to use. We have a waterborne finish called Kiilto and to apply it you do three very thin coats spread with a steel trowel and then two coats with the Flotex tool—no sanding between coats is necessary. I haven't used this finish in years, but for the first 15 years of my career I never had a buffer in my work vehicle because this was all I used.

Above you can see a tool used only in Finland; it's called the Flotex and it's a steel trowel with a type of flooring carpet glued to it. It leaves a very even coat, even while turning, and is a very fast tool to use. We have a waterborne finish called Kiilto and to apply it you do three very thin coats spread with a steel trowel and then two coats with the Flotex tool—no sanding between coats is necessary. I haven't used this finish in years, but for the first 15 years of my career I never had a buffer in my work vehicle because this was all I used.

9) I also don't have to worry about legal issues

Basically, I do not need to worry about legal issues with my jobs. There is a multi-layer system for disputes—some parts government-run and some organizations—and they work together to resolve disputes. It works like this: If the customer thinks there is something wrong with the product or job, they contact the provider and usually an agreement is figured out. If the flooring company says there is nothing wrong with the floor, the customer can submit a dispute online to The Consumer Disputes Board. The Consumer Disputes Board can and will advise the consumer to contact an inspector, who is a scientist with a degree and is an expert on flooring, who will come to a conclusion favoring one side or the other. Businesses comply with The Consumer Disputes Board in 80 percent of cases, and the Board handles the cases free of charge (costs are covered by the government). If the dispute continues it can go to court, where there is a third level of government settlement negotiation—kind of a light version of real court—before it ends up with an actual judge and full court, which is rare.

Here, spoken word is as good as a written agreement, and I rarely write anything before I do a job. Once the job is done, there are clear rules that make it very easy to enforce unpaid invoices.

|

A rare but useful tool: my planerA tool I find very useful is one that isn't made anymore: my Örebro GH-10 floor planer. Not many were made and few went to the U.S. market; the last ones were made in Sweden about 25 years ago. Fortunately, I have one I use and one that's still new. It runs with 220 or 380 volts, and it has two rotating blades with a speed of 3500 rpm/minute and an internal vacuum with 6500 rpm (this machine produces a lot of material). It's far more effective than anything currently on the market for removing material off the floor—paint or even nails are no issue with this planer. When people see videos of this planer on YouTube, they always want one! See a video of the planer: |