I grew up in my family's retail flooring business, but now I do wood flooring inspections, which makes some pros think I'm the enemy and out to blame them every time. I would love to not find installers at fault, but many times it is their fault, and when I ask for their moisture readings, they don't have any. Here are the absolute basics you should be recording on every single job.

1) Subfloor moisture

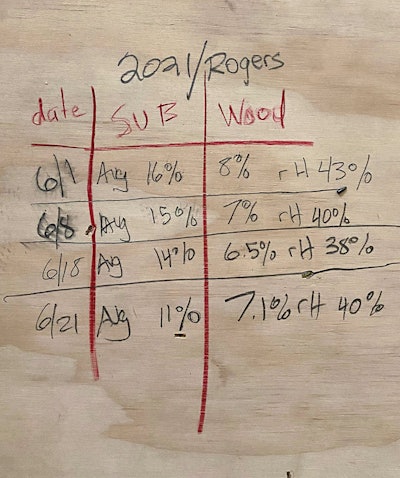

Before the wood gets to the job site, the subfloor should be measured; industry guidelines say 20 measurement points per 1,000 square feet. People immediately push back and say that's unrealistic, to which I answer, "Can we at least do 10?" Something is better than nothing. Take a photo of the moisture meter with the reading and write it with the date in Sharpie on the subfloor. That way, when you come back to check the subfloor, you can test in the same spots.

2) Relative humidity

Take and record RH readings throughout the job site, or at least where the wood flooring is going to be installed. Leave a hygrometer on-site (your hygrometers should be tested and calibrated to make sure they are accurate). It can be worth it to invest in one that gives you remote readings and also automatically records them.

3) Moisture below the subfloor

If the job is over a crawl space or basement, measure the moisture content of the joists or underbelly of the subfloor and record them. If you find it's elevated, you know that moisture will be going only one direction: up into your floor.

4) HVAC system

It needs to be functional, including the humidification system (which is highly encouraged).

5) Outside drainage

Make sure the grading of the yard goes away from the building, and that downspouts are installed and directing water away from the foundation. Take photos.

6) Manufacturer directions

Find out what the flooring manufacturer requires for the RH, temperature and MC of the subfloor and flooring. Keep a copy of the directions on the date you did the installation (they can change over time). Only after you have these measurements can you determine if you are ready to take the wood flooring to the job site.

7) Wood flooring MC

Testing (and recording) the MC of the flooring is the final piece of information you need before you determine if you can go ahead with the installation

RELATED: Limit Your Liability: Avoid Moisture-Related Claims on Wood Floors