When it comes to the sanding part of a job, it seems that, as an industry, we immediately jump to the minutiae of everything from abrasives to grit sequences to techniques for running each of the required machines. But that skips over an essential step—plugging in those machines to run them (and the job) safely and legally. In the following pages we referenced some of the industry's experts to provide a guide to powering up a wood flooring job in a way that's safe for the machines, the people running them and the job site itself.—K.M.W.

Where our electric terms come fromHere are some names to remember: Alessandro Giuseppe Antonio Anastasio Volta (1745–1827) was an Italian physicist, chemist, and pioneer of science in the Age of Enlightenment. He is credited with the invention of the storage battery. André-Marie Ampère (1775–1836) was a French physicist who founded and named the science of electrodynamics, now known as electromagnetism. His name endures in everyday life in the ampere, the unit for measuring electric current. James Clerk Maxwell (1831–1879) was a Scottish scientist in the field of mathematical physics. His most notable achievement was to formulate the classical theory of electromagnetic radiation, bringing together for the first-time electricity, magnetism, and light as different manifestations of the same phenomenon. Heinrich Rudolf Hertz (1857–1894) was a German physicist who showed that Scottish physicist Maxwell's theory of electromagnetism was correct, and that light and heat are electromagnetic radiations. |

Electricity terms: Do you understand them?

By Bob Goldstein

Getting to the source of power on our wood flooring jobs can be a challenge. In my decades in the industry, I have crawled through attics, utility rooms, basements and sheds. In those places I have encountered rats, mice, snakes, black widow spiders, brown recluse spiders, scorpions, squirrels, a skeleton of a cat, several large iguanas and a box of old Playboy magazines. Just another day living the dream! Before you get to the part where you're actually hooking up power, though, there are some basics that every wood flooring pro should probably know about electricity.

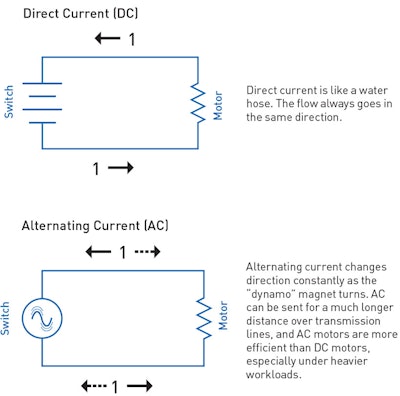

AC/DC

AC/DC is more than a 70's rock band. (If you are interested in the origins of direct current and alternating current, watch the 2017 movie "The Current War"). To keep it simple, both DC motors and AC motors produce usable work.

What the terms mean

Electrical current involves the flow of electrons. Here are some modern definitions you should know:

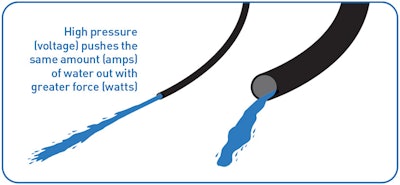

Voltage: the potential difference in force between two points.

Amp (short for ampere): the base unit of electric current.

Watts: the power in an electric circuit.

How they relate:

Watts (power) = volts x amps

A few electrons under a lot of potential can supply a lot of power, or a lot of electrons at a low potential can supply the same power. Volts is the pushing force, and amps is the amount being pushed.

Think of water in a hose:

FACT:In the USA most of our small tools and edgers use 110 volt AC power. Predominantly, the rest of the world uses 220 volt, as it is more efficient and more economical. You need to know the difference when you wire for a tool or plug in your machines. |

In this water and hose analogy, volts is the force of water pressure being applied and amps is the amount of water being pushed. A gallon (think amps) under low pressure (think low voltage) just dribbles out (think watts). Our machines need a given amount of current (amps) to run efficiently. If our pressure (voltage) is too low, then an excess of volume (amps) is needed to consistently deliver the needed power (wattage) at a given time. Amps also equal heat, so an excessive amount causes our machines to run too hot. Likewise, pressure (voltage) that is too high will also push through too much current, causing the machines to run hot.

Hertz (abbreviated: Hz): the unit of measurement for frequency.

Since frequency is measured in cycles per second, one Hz equals one cycle per second. Motors are built for the electrical frequency being produced. In the U.S., we use 60 Hz, but most of the rest of the world uses 50 Hz.

Wire size matters

As with the hose analogy, the size of the wire helps determine the efficient flow of electricity. The heavier the wire, the more energy that can travel through with less resistance (think of a fire hose and a garden hose). In our trade, we use no less than 10-gauge wire for our 240v equipment and NEVER run more than 100 lineal feet of cable (if you must go over 100 feet, you need to put a power booster in line and check with a voltmeter to ensure you have enough power to run your equipment without damaging it—more on that later).

Bob Goldstein, now retired, is a lifelong wood flooring pro.

Bob Goldstein, now retired, is a lifelong wood flooring pro.

Most important: Be safe

Alright, no pop quizzes. The most important thing to remember in our trade is simple: Electricity can hurt you; electricity can kill you. It wasn't that long ago that wood floor finishers would remove the protective cover on a fuse panel, use copper alligator clips and attach their wires to the main incoming wires—with no thought to safety. More than a few must have had an electrifying experience.

If you can't use available outlets, hire an electrician to hook up power for you (see what Daniel Boone has to say about selling that as part of the job below. And if for some reason you have to work with a three-phase system (like on a gym job), DON'T! Hire a professional to do it.

The more you know, the safer you will be.

Growing up in the industry, we did lots of unsafe things, and I had many close calls with electricity.

Growing up in the industry, we did lots of unsafe things, and I had many close calls with electricity.

Know your cords

By Daniel Boone

I'll be the first to admit that when it comes to electricity on a wood flooring job site, I've cheated and done all kinds of stupid stuff—I just feel lucky to still be here to tell you about it. When I was a teenager doing floors in Florida, the electric company would give floor guys meter boxes—little wooden boxes made with two-by-fours and plywood. On one side was a meter and on the other side it was a panel box. It's crazy to think about now, but you were allowed to climb the pole and use alligator clips to hook it onto the top leads, which would be 200 amps, and run your meter. The electric company would read the meter, and you had to pay for the electricity you ran off that pole. That's how stupid we were back in the day! I'm here to tell you to do as I say (and do now), not as I did.

I know most people don't do it, but your first step should always be to read your instruction manual for your machine. It will tell you the electrical hookup, the amps, the type of cord and plug for that machine, and the longest distance you can run a cord (100 feet). Having the right electricity means your equipment will run as it should—at the right temperature, meaning it won't overheat and will run more smoothly, giving you a better sanding job.

FACT:Buffers and edgers all require 110 power, so they can be plugged into any regular household outlet. Professional big machines all use 220 power, but they aren't all the same amps. Some, like the Floorcrafter, are 20, and others, like the Hummel, are 30. The cords aren't interchangeable, so you need to know which cord is for which machine. |

Cord Basics

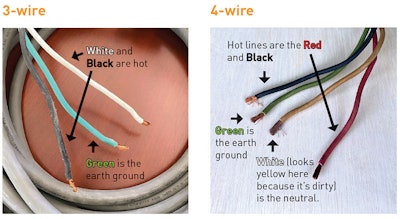

The cords we use for our sanders and boosters are 10-3 or 10-4. The "10" means the gauge of the wire (10 is extra heavy duty); the 3 or 4 means the number of wires inside. The 4-wire outlets are what everyone calls the "new" wiring (since 1996), but many times in an older home you'll still need to plug into a 3-wire outlet.

Most contractors make their own cords. Most cords only come up to 50 feet; if you want one longer you have to make it. You can buy the right cord from your local distributor and then attach a twist-lock plug (see the directions later in this article). It's better to have a 100-foot cord than plugging two 50-foot cords together because if the plugs in the middle don't have a good connection, they will create resistance and get hot.

Using damaged cords increases resistance, creating hotspots.

Using damaged cords increases resistance, creating hotspots.

Cord Maintenance

1) Check your cords before sanding. Before you start every job, make sure your cords are in good shape: no cuts, no frays, no big chunks missing, and no bare wires. A lot of guys just "flow and go"—they get right to work and then wonder why things are running hot or they smell something. If you're on a commercial job or a big residential job, an inspector will take a damaged cord from you on the spot (and you could be fined). In the old days if you were on a big job and had a damaged cord, they would immediately unplug it and cut it in half.

2) Periodically check the connections inside the twist-lock plugs. If they are loose you might not be getting the right power to your machine, and they can burn.

3) Walk your cords. Every time I take a break from sanding, I unplug and walk my cords: I feel the cord from end to end to see if there are any hot spots.

This big machine shows damage from a loose/worn out plug, causing arcing, and needs to be replaced.

This big machine shows damage from a loose/worn out plug, causing arcing, and needs to be replaced.

In 1975 we were sanding parquet that ran like a yellow brick road through carpeting in a new mall. I was edging and one of my dad's workers was running the big machine. I kept smelling that electrical burn smell. About 100 feet away we had a power booster, and the closer I got to that, the more I could smell it. When I got to the cord from the panel to the booster, the cord was melted into the new carpeting like a hot spoon in ice cream. Luckily it was probably fire retardant carpeting, so it was just sitting there bubbling and smoking. The connection had been loose at the booster, and that was enough to heat up that cord.

Sell safety as part of the job

When we are making money and want to get the job done, none of us want to wait for an electrician or hire someone to do something most of us can do in five minutes. But if you hook it up wrong and someone gets hurt or a fire starts, you will be liable. Or you could get seriously injured. You need to sell to the customer that doing it safely is part of the job. In my younger days, I've gotten thrown off a job for going directly into a panel, and I've also had a customer threaten to have me arrested (turns out it is actually a felony to pull that meter out of the box like I was doing on that job). I've also been on jobs with very close calls to my own life or someone else's. When I was in my early 20s, I had a 3-phase panel open. I was leaning in while holding onto a screwdriver. My dad reached over and tapped me on the shoulder to stop me—my hand holding the screwdriver was about half an inch from one of the main leads. In a three-phase panel, that would have blown me apart.

Some common but illegal things

Daniel Boone is the training manager at Sparta, N.C.-based American Sanders.

Daniel Boone is the training manager at Sparta, N.C.-based American Sanders.

FACT:One of the most common causes for failure of the sanding machine's electrical components is using too long of a cord for the available voltage on that job. |

How to power up for professional wood floor sanding

By Russ Watts

Probably one of the most overlooked aspects in professional wood floor finishing is all that goes into powering up your sanding machines. Is the power source at any given job site something you examine before you bid on the job, or are you in that group who just expect all to be golden the moment you plug in and engage that switch? Aside from checking the breaker box, do you have a plan to deal with instances in which your sanding machine fails to start or shuts down in the middle of a job? Maybe it is running poorly, bogging down or getting hot. These all can cost you an awful lot of time and profit. Knowing just a few things about the electrical world and the ways you can make it all work better for you adds efficiency and profitability to your floor sanding career.

A dryer outlet with the pre-1996 3-wire configuration.

A dryer outlet with the pre-1996 3-wire configuration.

Where can you find 220v power?

1) Outlets. Most modern completed homes and commercial buildings are equipped with power outlets, usually at the range or the dryer, intended for providing adequate power to run electrical appliances and motors rated for 220v power. These outlets come in a variety of slot configurations that require the correct plug to extract its power. For these situations, a short extension cord, often called a "pigtail," is typically used (see more on pigtails later in this article).

If you need to get power from a panel, I urge you to have it done by someone legally authorized to do so.

If you need to get power from a panel, I urge you to have it done by someone legally authorized to do so.

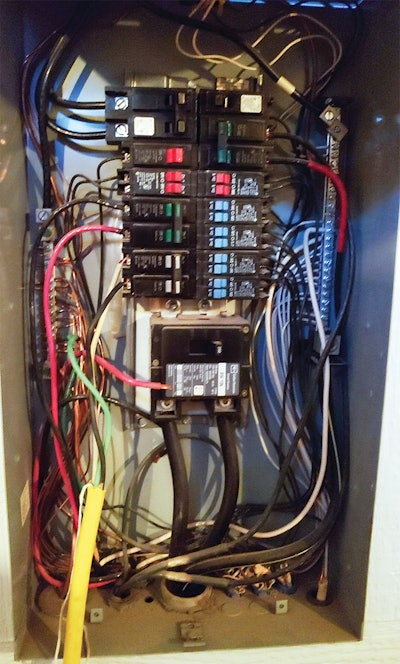

2) Breaker Panels. Nearly all modern homes and commercial buildings have breaker panels that distribute power and protect the various circuits from overload and/or ground faulting by use of breaker switches. If there is no usable 220v outlet to use for powering up a floor sander, the power in the breaker panel is used.

Extreme caution must be exercised if your power is extracted from the breaker panel. There is mortal danger present within these panels, and there also may be laws that prohibit the removal of the protective plate in order to access that power unless you are a licensed electrician. In the interest of remaining both safe and legal, I urge you to have this simple, temporary connection into the breaker panel executed by someone legally authorized to do so. All you normally need to provide the electrician is a connector that fits the plug end of your big machine's extension cord.

3) Generator. It is rare, but you may discover that the site where you intend to sand simply lacks the power, either by outlet or by breaker panel, to power up and sand that floor. Hopefully you have discovered this before you have placed a bid or invested in this job. In such cases, always communicate this with whomever you are consulting about this job. On a home under construction, it could just be that the 220v circuits are not set up yet. If you have detected this on your first walk-through, it doesn't take a fierce negotiator to get assurances this will be done well before sanding day. If all else is exhausted, then it just may take a generator to do this. For more on generators for floor sanding, see my WFB article "Tips for Running Your Sanding Equipment on a Generator."

Why measure your voltage?

If you seek to make the most of a not-always-predictable electrical world, there is no better bang-for-the-buck than a multimeter. Why use one?

Testing volts in a live outlet.

Testing volts in a live outlet.

Testing capacitance.

Testing capacitance.

Testing ohms in an extension cord.

Testing ohms in an extension cord.

1) No expensive surprises. With a multimeter, you can live-test an outlet and know how much voltage you have when you write an estimate. You can instantly know if more time and expense will be needed due to any electrical situation. It is far easier to write in the costs of renting a generator on the initial estimate than to discover you need one on sanding day. You can also determine if the 220v power in a house under construction has been set up.

Most importantly, knowing how to live-test any outlet can tell you everything you need to know about what kind of candidate it is for use. It may be usable as-is. Maybe it needs boosting or bucking. Maybe it is dead or disconnected. It might be a 3-phase outlet and you run single-phase equipment. If you do run 3-phase equipment, it is imperative you know whether your 3-phase power is low voltage (230v) or high voltage (460v) so you can make the proper changes inside that machine's switchbox.

2) It protects you. You can easily test any outlet to ensure that it is properly grounded.

3) It tells you if you need a booster. If you run multiple crews and have a limited number of boosters, you can know which jobs need one and which do not. By knowing what the voltage is at your job site, you can make good decisions about what lengths of cable you might be limited to using and whether or not to boost or buck with your power booster. (See details about boosters later in this article.)

4) It prevents costly repairs and down time. Electrical repairs to your sanding machine can be very expensive and can also mean lengthy periods of downtime. It is uncanny how those who invest a small amount of time to consistently use a multimeter experience far fewer of these costs.

5) It helps troubleshoot on site. Having a multimeter handy at the job site can provide enormous help should you encounter any unexpected electrical failures. You can quickly know if you are getting adequate power at the end of the extension cord and know whether the problem has to do with the job site, power booster (if used), power delivery string (all cable used to bring power into your sanding machine's switchbox), or the sanding machine's electrical system. Many times you can call your sanding machine's support hotline from your job site, and if you have a multimeter and know a little bit about using it, you stand the best chance of resuming your sanding.

6) You can test capacitance. Many big machine motors utilize capacitors—devices for storing a charge. The capacitance level of any capacitor has a number (usually in microfarads) stamped on its side that's required for proper motor operation. A multimeter that can test capacitance can quickly confirm the need to replace a capacitor should your machine get hot, run sluggish or be very slow to start up.

7) You can test ohms. Your extension cords, outlet pigtails and even any power-in pigtails featured on your sanding machines can routinely have ohms (resistance) tests performed on them to look for signs of trouble before it costs you on the job. These tests literally take seconds and can save you large expenses in repairs to equipment.

Russ Watts handles sales and service for Denver-based Lägler North America.

Russ Watts handles sales and service for Denver-based Lägler North America.

The list of extras for doing the best you can with electricity in floor sanding is not long or outlandishly expensive. A few pigtails, some extension cords, a power booster or two and a multimeter just about covers it. Throw in a roll of electrical tape, some extra plugs and connectors, maybe some wire nuts, extra automotive wire and cable into your toolbox, and you really should be well-equipped to face the not-always-predicable world of electricity.

A bad habit:

Most boosters display what the unmodified voltage is at the job site (as do some big machines). That is a nice feature but can potentially steer you into the direction of not knowing what you job site voltage is until sanding day. DO NOT let that happen to you!

The 411 on boosters

By Mike Rocher, Careen Ricks, Bob Mohr and Todd Love

Know this: Machines need a particular voltage

Electric motors are wound to optimally run on a particular voltage (the pressure needed to supply optimal amperage power or wattage), which can be found on the manufacturer's name plate on any electric motor. Electric companies have a range to meet when voltage service reaches commercial or residential locations; it varies from 200–250 volts in some areas, often referred to as high-line and low-line voltage. Running an electric motor on high-line or low-line voltage can cause serious damage to a motor.

By ohm's law, voltage and amp draw are inversely related: If voltage is low, your amp draw (and heat) go up. On the high line side, too much power runs directly through the machine, again increasing the operating temperature. In both cases, excessive or continuous heat will burn/damage the motor's electrical components. Knowing what level of voltage is pushing power to your machines (by taking volt meter readings at the plug that connects directly to machine, as discussed on page 37) ensures each machine has enough power to run effectively (with the correct cutting power) and efficiently (not too hot).

|

FACT:It's dangerous to remove the ground. In the event of an electrical fault/short (e.g. exposed wires, damaged wires, loose wires, etc.), the escaping voltage will travel the path of least resistance to ground, and this wire provides the easiest path to the panel and its earth grounding rod. Without this protection, you greatly increase the possibility that you become the grounding path. |

FAQs on boosters:

How much can a booster adjust voltage?

Most boosters give you the ability to boost voltage up 10–15%; a few also can buck, or reduce, voltage down by the same amount.

Can I use higher or lower voltage than what is recommended to operate my machines?

Optimal voltage is usually +/-5% from the recommended voltage.

How many machines can I run at once on a booster?

Even though you might be plugged into a 50-amp breaker (stove/oven outlet), the input/output receptacles on most power stations are rated for 30 amps at most. Some are only 20 amps, so know your equipment.

If you have three outlets on a booster with 30-amp inlet/outlet plugs (one 230v outlet, and two 115v standard outlets), the key is to add up the amp rating on the plates of each machine that you plan to use and don't go over a total of 30 amps, regardless of the number of outlets still open. To do this, you need to look up the FLA (Full Load Amp) ratings on your machines. Say you have a belt machine that runs at 23 amps, a vac at 12.4 amps, and a buffer at 15 amps. Given this scenario, you could run just the big machine (at 23 amps) OR the vac and buffer (12.4 + 15 = 27.4 amps), but not all three or you'd be over the 30-amp limit and risk damaging the booster and/or your equipment.

If I have a 4-wire booster but the only outlet is 3-wire, what should I do?

Make up several different 10-foot 3- and 4-wire pigtails that you can run from available 230v outlets to your booster (or to your first length of cable when traversing a large space). (You may want to have a qualified electrician make these up for you.) A typical setup might be one pigtail for a 3-wire dryer outlet to the 4-wire booster inlet (omit the white neutral wire); and a separate one for a typical 3-wire stove outlet. Then additional setups for a 4-wire dryer outlet (and a 4-wire stove outlet) to the 4-wire booster inlet. (See more about pigtails on page 40.)

What's the difference between single-phase vs. three-phase power supply?

Voltage is sent from electrical power stations over great distances, and it is less expensive to send it as 3-phase power (three hots and one ground), with less voltage per line (using less conducting material) but more total current. Because of the higher amount of power used in commercial facilities, they receive their electricity via this 3-phase configuration. For residential areas, the power is converted to single-phase at the transmission station and distributed. If you ever get a job in a commercial setting, don't assume their 4-wire twist-lock outlet is set up as single-phase (two hots, one ground, one neutral). Always test with your voltage meter so that you don't fry your booster, sander or other equipment from having three hots! In most single-phase commercial situations, you'll only be pulling 208v—which you can then boost to 230v.

Are all 3-wire or 4-wire outlets set to deliver 230v? If not, where might I expect lower and higher voltage situations?

As mentioned above, commercial work will typically have low voltage (208v). In some newer residential construction, it's not unusual to have 260v or more coming out of the wall, so you need to buck it down to 230v. Voltage can also vary during the day from electrical distribution facilities due to local usage (i.e. air conditioning in summer). If you notice your machine(s) bogging down, keep an eye on the big machine's inline voltage meter (if equipped) or the reading on your booster's meter. You may need to dial up the voltage (pressure).

What if I need to run multiple lengths of cable (greater than 50')?

As you increase the length of cable from the outlet to your machine, you are also increasing the resistance (and drop in voltage) of electricity to your machine = heat = early wear, as it tries to pull more amperage through to achieve full power. When running more than 50' of cable, boost the last 50' to your machine. For example, if 250' is needed, then run 200' from the outlet to your booster, and boost the last 50' to your machine. The most important voltage reading is on the plug end that goes directly into your machine.

For 115v machinery, use heavy duty 12-gauge extension cords when needed to reduce the resistance (heat) created by the longer reach.

TO BE SAFE, always contact a qualified electrician for your electrical needs. |

Mike Rocher, Careen Ricks, Bob Mohr and Todd Love are the service center crew at Bona US.

These pigtails are all I need to hook up power.

These pigtails are all I need to hook up power.

In cords like this factory-made 3-wire dryer cord, the wires are not a different color, but many have a different colored ring on the end, like the green you see here, or on the directions it will say which one is the ground. On all the ones I've seen the ground has been the middle wire, but that's important to verify.

In cords like this factory-made 3-wire dryer cord, the wires are not a different color, but many have a different colored ring on the end, like the green you see here, or on the directions it will say which one is the ground. On all the ones I've seen the ground has been the middle wire, but that's important to verify.

Pigtails: How-to

By Nate Sitz

The four most common 240v household receptacles a wood flooring pro will see on the job site are 3-wire range and dryer receptacles and 4-wire range and dryer receptacles (shown at right).

Simply unplugging the appliance and plugging in a pigtail is usually the fastest and safest method to supply power for the big machine. A pigtail is simply an adapter so you can plug your big machine cords into existing outlets. Those four cords, along with a pigtail with bare wires for wiring into a breaker (Note: This is not legal in many areas), are all I have ever needed to connect power on a residential job site.

Making your own pigtails is easy using store-bought appliance cords and twist-lock ends to match your power cords; these pictures walk you through how to connect a 4-wire range or dryer cord to a typical 3-wire twist-lock cord end.

In a 4-wire cord, the red and black wires are your hot wires and the green wire is the ground wire—needed in case of a fault. The white wire in a 4-wire cord is a neutral line. (That wire is not needed unless you plan on connecting to a power booster with a 4-wire input.) (See the cord photos.)

For 3-wire range and dryer cords, the white and black wires are the hot wires, and the green is the ground. Some cords like the one in the bottom photo do not have a different color on the actual cord, so pay attention to the factory-installed ends to identify the ground before cutting them off.

Common cheatsA lot of guys cheat when they have a 3-wire range cord and want to use a booster, which has a 4-wire cord. They make pigtails with the 4-wire cord end to plug into the booster by connecting the neutral and ground together. The outlet on the booster then works, but that's illegal. It basically makes the ground a current-carrying conductor, which is not allowed. The neutral always has some voltage—not much, but some. You don't want current going through the ground because if the ground touches someone, voltage can show up where it isn't supposed to be. Another thing I've seen is a cord where you can plug into, say, a bathroom outlet and another outlet on another phase, like a fridge outlet, at the same time to draw 110 from both and add up to 220. That's a bad idea because you don't have a 220 breaker that will trip if it needs to. |

A big panel oopsI had a job where I had to wire into the panel in a house that was undergoing major renovations (it's legal to temporarily use the panel here in Minnesota). But as I wired into it, the panel cover slipped and hit some of the breakers. Some of them had been off and some had been on, but I couldn't be sure which were which, so I just put them back to where I thought they were supposed to be. Turns out I was wrong: I turned off a freezer and thawed the cow inside it—$2,000 of meat. |

Making pigtails: step by step

Nate Sitz is owner at Park Rapids Hardwood Flooring in Park Rapids, Minn.

Nate Sitz is owner at Park Rapids Hardwood Flooring in Park Rapids, Minn.

RELATED: Sanding 101: Wood Floor Sanding Basics