From the time I was a little kid, I spent my summers with my grandparents in Utica, N.Y. My grandpa and I spent so many days together, but our time together might not be what you would expect. Even since I was five or six, I was tagging along with him in his work refinishing bowling alleys. I loved getting to spend all that time with him, and who would have imagined my experience way back then would steer my life toward running a successful wood flooring business today.

In those years, the '70s and '80s, bowling was still so popular that his company sanded only bowling lanes—they didn't do any residential or commercial wood flooring work. My grandfather and two of his brothers also owned two bowling centers in the area. I loved following him around on those bowling jobs, and when I was old enough, I started working with him—I thought it was fun. (Ironically, I never became a bowler! At his bowling centers my job was to eat cheeseburgers and fries.)

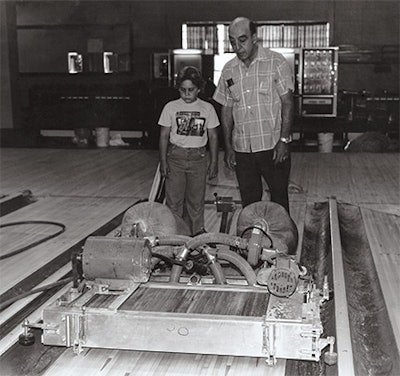

By the time I was eight or nine years old I was running a machine he had invented called the G&G Maxi Sander. What was unique about my grandfather's invention was that it stripped and leveled the lane at the same time. He loved it when I got on that machine, because when he was selling it to a prospective client, he could emphasize it was so easy to operate that even a kid could do it! And it truly was simple to operate.

He also invented a machine called the G&G Mini Sander, which was a 42-inch-wide belt sander that followed the Maxi Sander to close the grain back up in the wood to prepare the lanes for their finish coats. Those two machines he invented were his claim to fame, and they were expensive—somewhere between $10,000 and $15,000 even back then.

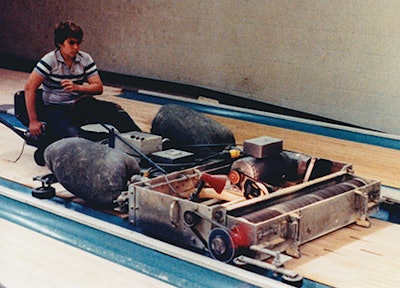

That's me running the G&G Maxi Sander. It was a unique machine because it stripped and leveled the bowling lanes at the same time.

That's me running the G&G Maxi Sander. It was a unique machine because it stripped and leveled the bowling lanes at the same time.

From running those machines I progressed to learning how to run the buffer and the 12-inch drum. Running a drum on a bowling lane was quite a bit different than using it in a residential setting. The 12-inch drums we used on the lanes all had special dual caster trucks on the front end so the edge of the drum could ride off the side of the lane to sand it. If you weren't careful, you'd go in the gutter and cause yourself some unnecessary repair work. Lanes we worked on were generally 39 or 42 boards wide depending on the installation style.

RELATED: A Look at the Dying Craft of Sanding & Finishing Bowling Alleys

Technical skills weren't the only things I learned from him on all those jobs, though. I also learned what it meant to have a work ethic and how to treat customers. I remember once when I was 10 or 11 years old I laid down—literally—while we were at a job to perform a task, and he said something to me about getting back up immediately. I remember wondering why he was yelling at me. On our way home from work that day he explained that the proprietors were there watching us do our work, and it doesn't look good if we are laying down on the job. That stuck with me to this day.

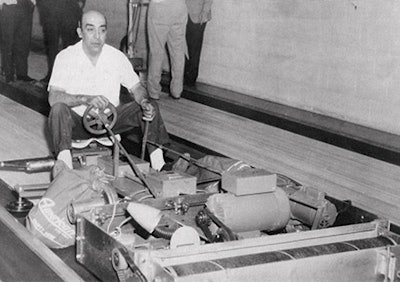

That's my grandfather running his G&G Maxi Sander.

That's my grandfather running his G&G Maxi Sander.

By the time I was 19 years old, I was still working for him in the summer while I was going to college, and by then he was sick with lung cancer. As he had aged, he had slowed down his work schedule. I knew the only reason he stayed in the business so long was because he saw I was interested in it, and he wanted me to know what I was doing. I remember one day traveling down the New York State Thruway heading to a lane sanding job, I asked him: "Papaw, do you think I can do this for a living and make money for the rest of my life?" He said, "Dan, there will always be wood to sand." At that time I had thought he was saying that there would be lane work forever for me to work on. Only now, given the path that my career went, do I realize what he meant.

He passed away that year, in 1991, but as it turns out, today I am still using the skills he helped me develop over the years. In 1996 I started my own business, Tru-Line Lane Service. It was my wife's idea that our business's name would pay homage to my grandfather: The sanders he had invented were called Tru-Line Longitudinal Lane Sanders, hence the "Tru-Line" in our business name.

As years went by, the bowling lane work slowly dwindled down, and it was forcing me to travel away from home to stay busy. Luckily I started to get more requests for home floor refinishing.

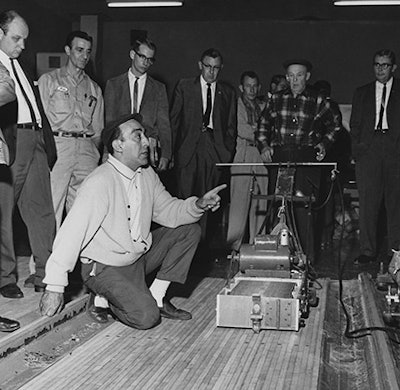

Here my grandfather is at a seminar demonstrating a prototype he was working on for lane sanding (that machine never gained traction like the other two did).

Here my grandfather is at a seminar demonstrating a prototype he was working on for lane sanding (that machine never gained traction like the other two did).

Around that same time there was a wood flooring company I came across in Syracuse, N.Y., that was advertising dust-free floor sanding. My father in-law and my wife said I should call the owner to find out more about this dust-free sanding. I told her I wasn't going to call him, but eventually curiosity got the best of me. The owner, Scott Schneider, helped me out a lot as far as learning how the residential side of the business works. It's funny now to think about those days: I had to borrow money from my grandmother to buy my first dustless system, and I put an ad in the paper and wasn't getting any calls. I felt like I was begging people for work. But Scott told me to be patient and the work will come, and he was right.

Over the years the business just evolved, and it keeps evolving daily. I think a big reason is because I am holding true to my roots and treating customers how my grandfather wanted his customers to be treated, with patience and complete honesty, all while genuinely listening to their concerns.

Today we have more business than we can handle. My wife and I have two and a half employees and a showroom. We're limited only by finding new hires with the kind of work ethic my grandfather valued. I still find this business as interesting as I did when I was following my grandfather around at the bowling centers. It's very gratifying: When I get to a job and I see it, I know exactly what to do, and I like that feeling. I also enjoy doing site visits to clients' homes to see exactly how my business can help them out. I think if my grandfather were still here today, he would be tickled pink that I'm still using the skills he began teaching me so many years ago.

RELATED: Blast From The Past: Wood Floor Tools and Machines from Yesteryear