It took me months to compile this simple Part 2 for Mystery 10 because the coronavirus knocked me on my tuchus. The very real “COVID fog” pushed me to compose blogs like I was remastering the Beatles’ Abbey Road medley! Three dead-end stories and no McCartney and Lennon to pull it all together! So, post-fog, let’s get back to it!

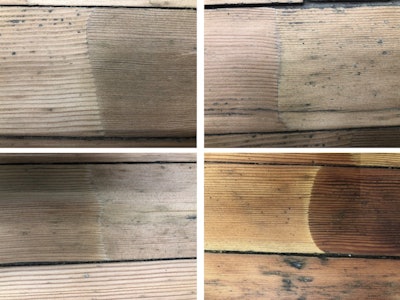

In Mystery 10 I showed you these floor photos sent to me by floor pro Tim Bird:

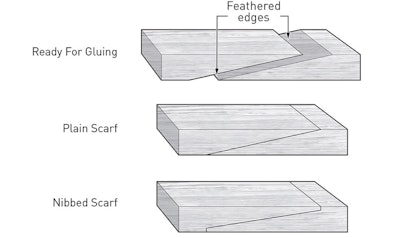

We asked you what they were, and, as many online readers correctly identified, the mysterious end joints are “scarf joints” (sometimes spelled “scarph joints”). To be even more detailed, I would call these “feathered and nibbed scarf joints.”

There are different scarf joints, but the very steep angle of cut shown here indicated these were “feathered.” Tapers in scarf joints are generally cut at an angle between 1:8 to 1:10. Feathering is cutting the joint to a fine, thin point that helps to obscure the joint in finish work. A 90-degree nib, which resembles the common “rabbet” joint, is used for stability and squareness:

My conclusion that the flooring was “nibbed” is because the deeper the flooring was sanded, the wavy joint visually becomes became square again. The tiny piece of the feathered corner not completely sanded exposes the square nib joint which lies below:

Notice there is also a foggy, thin, lateral line that separates the two pieces? That should be glue and wood fiber used in the lamination process

Just for fun, I reproduced a scarf myself using scraps from my warehouse, a miter saw to make the cuts, and a folded edger disc to sand the surface:

Why would a mill laminate scarf joints in fir decking/flooring? I surmised that since exterior decking of the 1800-1900’s was a cheap and popular source of hardwood flooring on second floors and informal areas… well, even better if it looked like it was long-length. In addition, exterior decking was often installed with full-length pieces as to avoid exposing butt joints to the elements. Visually, scarf joints would have been no issue since most exterior decking was painted. Could this have been a rogue Vermont mill offering long length fir flooring? Genius!

I decided to set out for the Benson Village Store in Vermont where Tim Bird took these photos. I texted Tim, asking how I might be able to get a look at the actual flooring, but, sadly, the 157-year-old historic building had burned down in April of 2019 and then completely torn down:

From Bird’s photos, we know the material was not repaired with scarf joints on-site, as the tongue and groove joints were undisturbed—these boards must have been scarfed prior to installation.

As I found no such material online and with no shot at inspecting the floor, this little mystery of why there were scarf joints in a wood floor remained unsolved. Then Kenneth Varnes of Quality Hardwood Flooring in Harrisburg, Pa., posted a single blurry photo on Facebook:

He had a rental unit with what appeared to be dozens of these exact scarf joints. Could these be scraps from an old exterior decking installation? The visual proof: Classic 3 1/8-inch-wide, ¾-inch-thick, solid, vertical grain fir flooring/decking, with the very same material and scarf joints, just six hours south in what was once … a vintage general store.