Seeing Spots

I just sanded and finished a Brazilian cherry floor, and now there are little white spots all over. What causes these, and how can I prevent them?

Daniel Boone, president at DeLand, Fla.-based Everwood Floors Inc., answers:

These spots are caused by resin pockets in the wood. Any time you finish Brazilian cherry with urethane—oil-modified or waterborne—these pockets actually break the finish bond, and the white spots result from the finish not bonding and drying properly.

One way I've found to avoid getting the spots is by wiping on and wiping off a thin coat of urethane. To make it easier on yourself, you can even buff the finish into the floor. Buff multiple coats on in order to get a seal. Do this several times, and then abrade with a maroon pad.

Finally, apply a couple topcoats of urethane with whatever type of applicator you typically use: T-bar, roller or brush.

But probably the best product to use to keep Brazilian cherry from showing the white spots is a solvent-based finish such as conversion varnish, universal shellac or moisture-cured urethane. The moisture-cured urethane may not be an option for people in the Northeast or California, but it's the best guarantee I've found to avoid those white spots.

Gluing Down Solids

Can I really glue down 3/4 -inch solid wood flooring?

Bob Sweezey, technical director at Memphis, Tenn.-based adhesive manufacturer Stauf-USA, answers:

Solid products have been glued down overseas for many years and have also been successfully installed throughout the United States. A solid product from 5 / 16 to 3 / 4 inch thick can be glued within the following parameters: • Both the flooring manufacturer and the adhesive manufacturer must recommend their products for glue-down installation of solid wood flooring. Check with the wood flooring manufacturer for which adhesive is recommended; I recommend only adhesives with zero water (polymer or moisture-cured urethane adhesives). The proper notched trowel must be used.

• The installation must be installed on grade or above-grade.

• The concrete subfloor must measure under 3 pounds of moisture per 24 hours per 1,000 square feet when using a calcium-chloride test.

• The concrete must be free of sealers and contamination (dust, paint, adhesive residues, etc.).

• The concrete must be flattened (as needed) to within 3/16 inch per 10 feet, grinding it down in high spots and using a leveling compound of 3,500 psi for low spots.

• As with any installation, humidity and temperature must be controlled using a humidifer, dehumidifer or both to prevent excessive expansion and contraction. The acceptable range is between 35 to 65 percent relative humidity and 60 to 80 degrees Fahrenheit.

• The wood flooring must be straightline ripped to ensure absence of crooks (where the ends touch the adjoining board and the middle does not, or the middle touches the adjoining board and the ends do not). Crooks can usually be corrected in a nail-down installation, but will never be held by glue.

• Bowed boards (lifted in the middle or on the ends) can be remedied by adding weight (i.e., boxes of wood yet to be installed). Glue will not reach up and grab a bowed board—installers must ensure contact. Failure to make contact with the adhesive results in hollow spots, and this in no way is a glue failure.

As with any glue-down installation, clean-up with the appropriate adhesive cleaning agent is the professional way to complete your installation.

Floor Identification

When I have a remodel job with a floor needing repairs or I need to add to an existing floor, how can I identify what species the floor is?

Cort Dunlap, NWFACP-certifed inspector and sales counselor at Seattle-based Hardwood Inspections, answers:

How many remodel jobs have you walked into, looked at the floor and had no idea what the wood was? The floor is 20 years old, and the homeowner has no idea what it is. Red or white oak? Is it Northern or Southern material? Is it a clean No. 1 common or a dirty select floor? During my years working at a distributor, I often had installers come in and ask, "What is this?" Being sure of the grade and species can save you lots of time and money; you don't want to make your first cut sanding and then realize the floor is a different product from what you thought.

There are a few ways to help you identify the wood that you may be contracted to refinish and/or add on to.

Checking the floor by lifting a vent or scraping some shavings in a closet can give you a clearer look. If you are sure it is an oak floor but can't determine if it is red or white oak, test it (there's an easy test kit available for this; every installer should have one).

Another item to have is a digital camera. Take some photos of different areas of the job site and bring them in to your local distributor. They can look at the pictures and assist you with identifying the species and the grade of the material.

Also check with the homeowners to see if they have any leftover material you could bring with you. Having the pieces can make it much easier to identify species and grade.

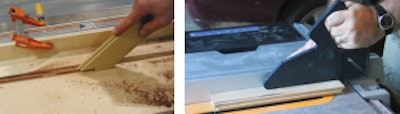

Trick of the Trade: Give it a Push

Here's something that should be standard issue with every table saw at every job site: a push stick. You can buy them, from simple versions to the multi-functional (at right). In a pinch, you can make one from a piece of scrap wood (at left). Or, you can make your own higher-end version—free patterns for making ergonomic push sticks are available at many Web sites; just Google "push stick." What's important is that you find one that's easy for you to use; that way you'll actually use it and keep all your digits out of harm's way.1