We all know the majority of wood flooring complaints are moisture-related. Although the relationship between water and wood can seem mysterious and complex, wood actually responds to moisture changes in predictable ways. Here's a look at the basic science behind why wood moves the way it does when it comes in contact with moisture. Once we understand that, we can end up with fewer problems, better floors and happier customers.

Under the Microscope

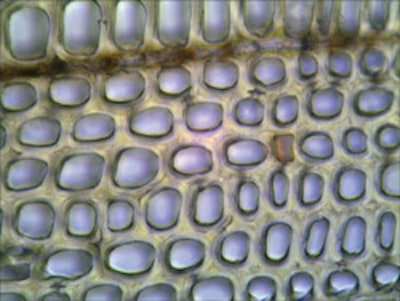

The cell is the basic structural unit of wood. Most wood cells are hollow cylinders, which you can see in the photo at right. In softwoods, the long dimension is typically 100 times greater than the diameter, and cells can average ¼ inch long. Hardwoods have a more varied cell structure, but the basic shapes are similar. The vertical direction in the stem of a normal tree is called the longitudinal direction; most cells are oriented in this direction.

Variations in cell type, size, and wall thickness give rise to the visual characteristics of wood such as growth rings and grain. Cells formed early in the growing season-earlywood-usually have larger diameters and thinner walls. Cells growing later in the year-latewood-have smaller diameters and thicker walls. Several layers comprise the cell wall, but most of the structural properties are dominated by the thickest layer, called S2.

Ray cells are aligned from the center toward the bark radially instead of longitudinally. The light flecks, or rectangular patches, in quartersawn white oak are rays. The number of ray cells varies considerably between species; this affects the appearance and structural characteristics. Large rays contribute to both stability of quartersawn lumber and its tendency to check along the rays.

The center piece demonstrates compression set: It was cut, soaked while restrained from swelling, and redried. It is now slightly narrower.

The center piece demonstrates compression set: It was cut, soaked while restrained from swelling, and redried. It is now slightly narrower.Where the Water Goes

The hollow centers in living wood cells usually contain water. When liquid water is present, the wood is above the fiber saturation point (FSP). Above the FSP wood does not shrink or swell when its moisture content (MC) changes. Below the FSP, however, wood changes size when the MC changes. MC is defined by the ratio of the weight of water in wood to the weight of all the other material (its dry weight).

Cellulose typically accounts for almost half of wood's dry weight. Cellulose is a chain polymer that is extremely long compared with its width and has high bond strength, which gives resistance to elongation or breaking. Cellulose mostly aligns with the long axis of the cell. Along the sides of the cellulose molecules there are locations where water molecules can attach with a chemical bond. When relative humidity (RH) increases, more water molecules adhere to the sides of the cellulose-it gets fatter but not longer. The result is that the cell walls get thicker, causing the boards to expand. However, there is almost no change in cell length, so there is almost no change in the length of the board. When the humidity goes down, the process reverses: Water leaves the cell walls to go into the air and the wood shrinks.

Reaching Equilibrium

The Equilibrium Moisture Content (EMC) as a function of humidity is not strongly species-dependent. EMC values are in the Wood Handbook: Wood as an Engineering Material (the new "Centennial" version is available for free download from the Forest Products Laboratory at www.fpl.fs.fed.us/products/publications/pubs_interest.php). Realize, though, that wood properties can vary between different pieces within the same species, so several readings should be taken to measure flooring MC (a wide variation in MC can indicate a problem).

Many species have longitudinal shrinkage from FSP to ovendry in the range of 0.1 percent-small enough to be unimportant in most flooring installations. But shrinkage of 10 percent is not unusual for flatsawn board face widths for the same MC change. For most species, quartersawn lumber is significantly more stable (1.5 to 2 times). The difference is caused by the ray cells, the different stability of earlywood and latewood, asymmetric cell wall structure, and pit location. Since expansion takes place in the cellulose, portions of wood that are denser tend to shrink more.

Flatsawn and quartersawn expansion coefficients (tangential and radial) and shrinkage values are available in the Wood Handbook; shrinkage values are also at www.fpl.fs.fed.us/research/centers/woodanatomy. You can use these to calculate change in size for moisture changes. If you know the seasonal change in humidity, you can predict how much the wood will change in size. Or, you can do the reverse: If a board changes size, you can calculate the moisture change necessary to account for the change.

When humidity changes, wood eventually reaches a new EMC. This takes a significant amount of time as the water diffuses through the wood, so we shouldn't expect a wood floor to reach a new equilibrium in just a few days. Floor finishes slow the rate of moisture change in wood but do not stop it. The process of shrinking and swelling can be repeated many, many times, although some of the water bonding sites are lost after numerous cycles, so the dimensional change diminishes.

MC vs. EMC

Moisture Content (MC): The mass ratio of water content to wood substance. In theory, it can be measured at any instant.

Equilibrium Moisture Content (EMC): The MC that wood will reach when it has been in an unchanging environment for a long enough time. Relative humidity tables are given in terms of EMC.

An easy way to understand MC versus EMC is to think about putting a piece of cold iron in a hot oven. It will have a temperature at any time but only after long enough will the temperature be that of the oven.

RELATED: Wood Floor Cupping: Why Does it Happen & What Can You Do?

Wreaking Havoc

With non-equilibrium conditions, it is possible for a moisture-caused dimensional change to generate unbalanced forces within wood. Cupping is an example: Internal forces generated by swelling of the wet side of a board are sufficient to distort it. Compression set, when boards swell against each other, is another example of swelling generating large forces within wood. The force is greater than the compression strength, thus the cell structure changes. Unlike cupping, which is often reversible, compression set remains after the wood dries.

Too-rapid kiln drying can cause other failures. In the kiln, as the outside (shell) of wood dries, it shrinks. The center of the piece, however, is still at a higher moisture level, so it shrinks less. Tension is created in the shell. If the tension is below the elastic limit, the deformation will reverse when the force is removed. But if the force is above the elastic limit, the wood does not recover its original size when the force is removed (case hardening). In more extreme cases, the wood cracks (drying checks). Even if the checks appear to close later in drying, damage remains and the product is susceptible to failure. Residual internal forces can become evident when part of a board is sawn off and the board distorts as it is sawn.

Of course, plywood has better stability. In plywood, shrinking and swelling caused by moisture changes can be diminished by 95 percent compared with flatsawn boards. The more stable longitudinal crossplies restrain the less stable flatsawn wood (tangential) of the adjacent plies.

Dry Cupping

Engineered flooring is often constructed with a thin piece of solid wood glued to plywood. In dry conditions the wood in the top layer attempts to shrink across its face. The shrinkage of the plywood backer is considerably less. This can cause dry-cupping or even promote cracks in the face similar to checks formed in rapid drying. Concerns arise when the EMC is significantly different from the manufactured value. With solid wood, we usually think of excessive moisture causing cupping, but for engineered flooring, low humidity during the heating season in cold climates or arid regions can cause cupping.

When planning wood floor installations, it is important to start with the moisture of the flooring at the appropriate level for the site. The difference in expansion coefficients between the longitudinal and cross-grain directions makes moisture issues especially important for installations with borders or feature strips.

RELATED: Engineered 101: Understand the Fundamentals of Engineered Wood Flooring

Wood is a complex composite material that takes some experience to master. But with a good background in the behavior of wood and careful planning, you should be able to avoid the disappointment of seeing thousands of dollars of product curl up. Instead, you can enjoy the satisfaction of seeing floors look great years after installation.

Further Reading

Notes from the author on recommended wood science resources for wood flooring professionals:

insidewood.lib.ncsu.edu/links: This is an extensive site that includes "Wood Identification for Flooring Professionals" by Dr. Wheeler, available from its links page. The site's search feature encompasses a huge database of information on hardwoods. It takes a little practice to navigate around the site.

www.forestprod.org: This site has publications for sale on water and wood relations including the Otto Suchsland book Swelling and Shrinking of Wood: A Technology Primer, as well as a good introductory CD on general wood properties.

Books by Bruce Hoadley, F.W. Jane (out of print but available used), C. Skaar (out of print but available used), and Jim L. Bowyer (with Rubin Shmulsky, John G. Haygreen) all have more details on wood structure and water relations. Other than the Hoadley books, these are beyond the scope of interest of a casual reader.

The World Resources Institute's (WRI) Sustainable Procurement of Forest Products is an excellent resource with guides for legal sourcing and examples of documentation. Two very comprehensive guides on legality are available for free at www.sustainableforestprods.org