The Problem

Recently, I was called to refinish an old parquet floor in a high-rise condominium. This was a simple pattern that was finished natural with old polyurethane. The floor finish was in poor condition, but no wood repairs were required. However, there was a huge rush to get the new owners in on time, and as we were sanding, we ended up creating the need for a wood repair!

The Procedure

The 5⁄16-inch-thick, quartersawn red oak parquet was glued down over a 1⁄4-inch-thick cork sound isolation pad. This was the required sound product when it was installed in the late '80s. As far as the sanding, there were no major concerns other than where heavy pieces of furniture had sat for years, lightly compressing the cork underlayment. This created low areas that required some extra care with the sanding procedure, but nothing any qualified sander could not correct.

During the sanding procedure, the client wanted to go through the color choices starting from a light golden brown to a water-based natural. After losing a couple of valuable hours of time going over color selection with the owners, they chose a simple natural oil-modified polyurethane. This was great, because we now could make up for lost time and be sure we could meet our move-in deadline.

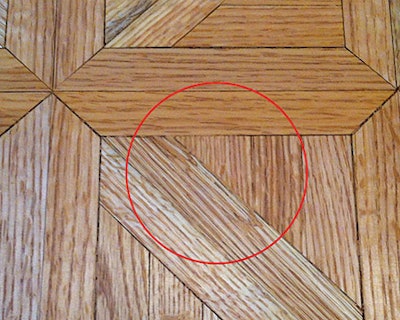

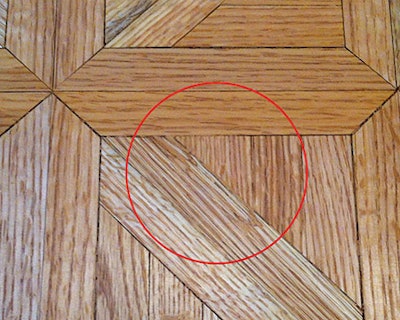

We completed the final sanding cut and were ready to buff out the floor to remove the sanding scratches with three hours left of our allotted time before building management would arrive to shut us down for the day. While buffing, the paper caught a piece of shake and shredded it to pieces. We had no flooring material at the job, the installers were on the other side of town, and we had no distributor within 15 miles.

The Cause

To buff the floor, we were using 120-grit gold discs, which had worked well for us in the past. This time, however, when buffing in the bedroom, the buffer paper caught a piece of shake and ripped it to bits. This was a major hiccup, since, as already mentioned, there was no ready option for fixing the floor.

How to Fix the Floor

The lead sander said, "Well, looks like this is going into next week." My first impression was that he was right. However, as a contractor, I couldn't accept that—I needed to meet the deadline, so I had to make the repair happen somehow. I knew we had no flooring material on site, and there was no other carpentry going on in the other units where I could borrow a piece of red oak baseboard to make a slave joint and piece it in. Filler was out of the question due to the size—this was 3⁄8 inch wide and almost 2 inches long—and dry time, which would likely take hours.

In the Future

It's important to do a pre-inspection before sanding, no matter how much of a rush you are in! Rift and quartered have a tendency to have more shake than other cuts of wood, but you can find shake in many other floors. Since then we found that using the new powerful LED flashlights held low (below your knees) to shine across the floor will reveal many flooring imperfections, including shake. And we now have Super Glue in each toolbox to instantly take care of minor problems such as this one!