A data logger from the week before the inspection showed the RH ranged from 14–25%.

A data logger from the week before the inspection showed the RH ranged from 14–25%.

The Problem

I was called to inspect the basketball floors in a new practice facility in a dry climate in the West because of concerns about gapping.

What Happened

Over the span of two weeks in August, a plywood anchored subfloor system was installed over the concrete slab covered by a 15-mil moisture barrier. During those weeks the 25/32-inch solid maple flooring acclimated in the facility. It was then stapled to the plywood subfloor, sanded and coated. While the flooring was being installed the HVAC was temporarily running, door openings were temporarily covered by OSB, and wet work was still being completed in the building. By November, about a month and a half after all the flooring was completed, gaps were noticed between groups of boards throughout the installation. The flooring contractor said all moisture readings of the flooring and subflooring and ambient conditions were in recommended ranges at the time of installation but could provide no documentation of them.

The Inspection

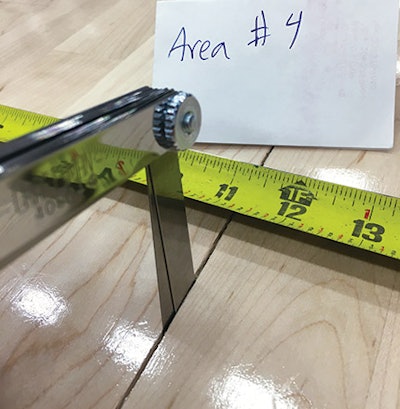

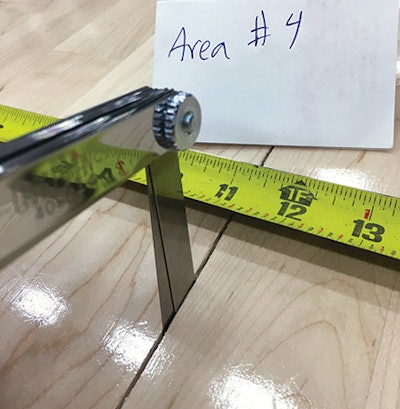

When I arrived in late November, from a standing position there was visible gapping between boards throughout the floor. The width of the gaps averaged 0.049 inch, and the MC of the maple ranged between 7–8%. The average board width was 2.231 inches. A data logger from the previous week showed the RH ranged from 14–25%.

Because we didn't have the data from the time of installation, I couldn't compare the MC and RH levels to those at the time of installation, but the boards measured under their expected manufactured width, and the RH was below the recommended range of 30–50%.

How to Fix the Floor

The initial recommended fix for this floor was to increase the RH, but due to the engineering of the building this was not possible—the facility was engineered as a "dry building," meaning that moisture to help stabilize the RH would make the Sheetrock on the walls literally fall apart. Additionally, the air system uses fabric socks, which cannot handle moisture. As of this writing, this floor continues to separate, with some gaps exceeding 1/4 inch.

In the Future

Buildings must be engineered to consider the requirements of all the materials, including the wood floor. If adding humidity is not possible, then the flooring must be acclimated to the expected RH before installation.