Wood flooring abounds in modern building construction—from apartments to homes to workplaces. It wasn't always like that. The popularity of using wood as flooring has ebbed and flowed throughout recorded human history. And although its origin as flooring is traditionally linked to the Middle Ages, there's evidence tracing wood plank floors all the way back to the Hittites—6,500 years ago.

We've compiled a timeline of some of the milestones that have helped to shape wood flooring as we know it today. The historical timeline presents a story of innovation and hard work—a theme that connects craftsmen and women of today with those from centuries ago.

4000 B.C.E.

The first evidence of resins from tree sap used as adhesive. Animal glue is also developed in this time period, and varnishes are frequently used to decorate tombs.

3000–1050 B.C.E

Timber is used in combination with brick for housing construction in ancient Egypt, mainly for doors and ceilings. However, brick stairs are occasionally surfaced with wood to protect them against wear. Prototypes for the tools that will become essential for hardwood flooring professionals are developed, including saws, knives, chisels and hammers made of stone or wood. Quartz sand is used as an abrasive, and tools are rubbed against pieces of sandstones for sharpening.

1600–1178 B.C.E.

Hittites may have used wooden planks for flooring in caves near the Black Sea.

1050 B.C.E–500 C.E.

The Greeks and Romans are credited with refining the art of veneer, marquetry and wood inlays, bonding sections or layers of wood with animal and fish glues, as well as creating adhesives from egg whites.

This miniature from 'Chronicles of Hainault' depicts a 15th-century construction site.

This miniature from 'Chronicles of Hainault' depicts a 15th-century construction site.

476 –1453

As buildings and castles expand, so does the use of wood planks as flooring. Timber, mainly oak, begins to be harvested from managed forests and cut cross-section with a saw, often using the entire trunk to create beams or planks. In "Medieval Architecture" (2002), historian Nicola Coldstream describes the atmosphere of the Medieval job site: "A building site was a noisy place. Permeated with the dust of lime mortar and the residues of cutting stone and wood, it rang to the sound of hammers, chisels, axes and saws, as well as the shouts of the workforce as they manoeuvred materials and machines into position. The simultaneous performance of so many different tasks gave an air of barely controlled chaos."

|

"Next I sheared off all the light wood of the long-leaved olive, and rough-hewed the trunk upwards from the root, and smoothed it around with the adze, well and skilfully, and made straight the line thereto and so fashioned it into the bedpost, and bored it all with the auger. Beginning from this bedpost, I wrought at the bedstead till I had finished it, and made it fair with inlaid work of gold and of silver and of ivory." |

1686

The Hall of Mirrors in the Palace of Versailles is constructed for Louis XIV. The parquet floor, which extends a length of 246 feet, is one of the most famous in the world and a prime example of the ornate wood floors constructed in palaces at the time. To create the floor, carpenters use hand tools similar to those developed in ancient times, including draw knives for smoothing wood planks, hand saws, drills, hammers and rulers, according to historian James Barter. The nails used at the time are hand-forged and feature squared shanks. The French elite carved the way for using wood floors in a decorative capacity.

The floors of Stenton, a house constructed in the 18th century in Philadelphia. Photo courtesy of The National Society of the Colonial Dames of America.

The floors of Stenton, a house constructed in the 18th century in Philadelphia. Photo courtesy of The National Society of the Colonial Dames of America.

1750–1800

A majority of American houses have floors of bare wood, according to the National Trust of Historic Preservation. In New England, virgin stands of white pine are sawn into flooring planks 12–16 inches wide and surface-nailed directly onto joists. As white pine is rapidly consumed by the timber industry toward the end of the 18th century, yellow pine planks cut in 5–6-inch widths are substituted. Long boards spanning the length of the rooms are the most coveted. Random-width boards are considered the "mark of a floor of poor quality." The floors are cleaned by scrubbing with water and sand, sometimes with the addition of wood ashes. The floors are never treated with high-gloss finishes or varnished, but pine floors are occasionally coated with paints made of white lead, pigments and linseed oil. Colors of surviving floors are yellows, dark reds, grays and browns. Geometric shapes such as squares and diamonds are occasionally painted to imitate more expensive marble floors.

1754–62

Architect Francesco Bartolomeo Rastrelli oversees the construction of the Winter Palace for Empress Elizabeth, the daughter of Peter the Great. It is the oldest of a complex of buildings constructed throughout the 18th and 19th centuries that now make up The Hermitage Museum in St. Petersburg, Russia. The elaborate parquet floors throughout the buildings would become some of the most famous in the world and are considered prime examples of Russian Baroque architecture.

Courtesy of the Library of Congress

Courtesy of the Library of Congress

1800–1840

Softwood floors continue their prominence in houses, although planks begin to be narrower, around 4–6 inches wide, due to second-growth timber and standardized milling practices. Painting wood floors is commonplace, with Thomas Jefferson's green-painted entry-hall floor at Monticello serving as one of the most prominent examples. The geometric cherry and beechwood parquet floor in Monticello's parlor, likely modeled after floors Jefferson saw while serving as Ministry to France in Paris (1784–89), would also become a signature parquet flooring style.

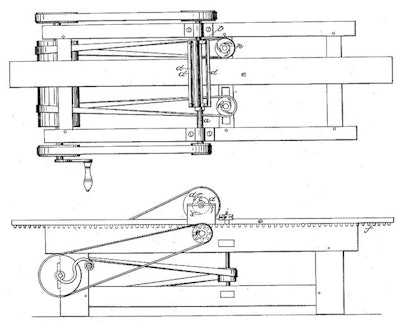

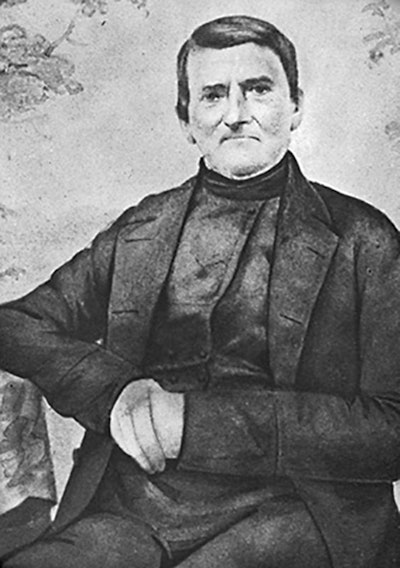

1828

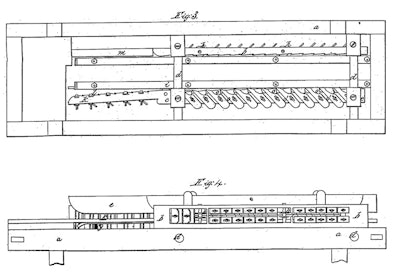

William Woodworth patents the first planing and matching machine, changing the lumber industry forever.

1828

As the Napoleonic wars stifle animal hide imports, German tanner Eberhard Stauf begins boiling his animal hides into glue and selling it under Stauf Adhesives.

1840–1875

Wall-to-wall carpeting comes into fashion in upper-class American homes. "By mid-century, architects and critics complained that the use of floor coverings was so widespread that few carpenters bothered to lay wood floors well, knowing that their work would only be covered," according to the NTHP. Yellow pine remains the most common wood flooring used, and sawmills produce planks in standard widths. The most high-end flooring is tongue-and-groove, which is not varnished but continues to be painted in kitchens, halls and bedrooms.

1852

Ransom Crosby and Henry Edgcomb of Crosby & Edgcomb in New York receive a patent for a wood planing machine designed to tongue and groove flooring boards.

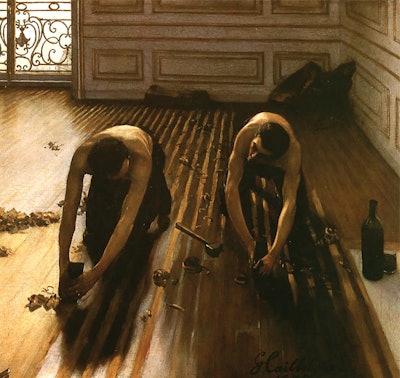

1875

French artist Gustave Caillebotte completes "Les raboteurs de parquet (The Floor Scrapers)," an oil painting depicting hardwood flooring scrapers at work. The depiction of shirtless working-class men causes a scandal in the art community.

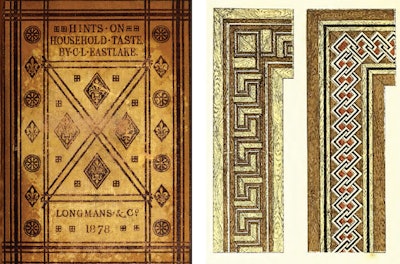

1875–1900

American architects and designers are influenced by English design critic Charles Locke Eastlake and his widespread book, "Hints on Household Taste in Furniture, Upholstery & Other Details" (1868), which arrives in America in the 1870s. Eastlake's case for simplicity in design propels wood floors into the limelight and makes them the "popular choice" rather than one "prompted by rude necessity," for the first time, says the NTHP. American sawmills increase design offerings, with hardwood parquet squares ranging in thickness from ⅜ inch to 1⅛ inch. Thicker parquet is tongue-and-grooved, and thinner parquet is glued and face-nailed in place. As an 1895 parquet floor catalog by manufacturer S.C. Johnson in Racine, Wis., notes, its thicker (⅞-inch) tongue-and-groove parquet enables the flooring to be blind-nailed.

1885

Frank Norton, a potter in Worcester, Mass., incorporates The Norton Emery Wheel Company to commercialize the company's vitrified-bonded abrasives. The abrasives are created by fusing clay and emery at 2,300 degrees in a kiln.

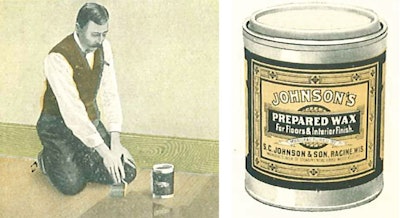

1886

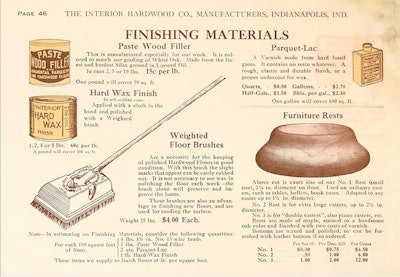

Samuel Curtis Johnson establishes S.C. Johnson, a Racine, Wis.-based hardwood flooring manufacturer. Bombarded with maintenance questions from clients, he introduces Johnson's Prepared Wax two years later. His wax finish, sold for $0.60 a pound by 1905, later outsells his flooring. (Flip through a 1905 S.C. Johnson catalog here.)

1891

Edward Goodrich Acheson, a chemist in Monongahela City, Pa., is credited with the invention of silicon carbide abrasives ("carborundum"), an artificial abrasive, and forms the Carborundum Company. Up until this point, abrasives were made out of emery, corundum and garnet. (Watch a video of Acheson reenacting his discovery here).

Photo by Juli Etta Photography

Photo by Juli Etta Photography

1893

The first European basketball court is installed in a YMCA in Paris. The oak herringbone floor is considered the oldest known basketball court today. (Read more about the historic court here.)

Photo courtesy of the National Archives

Photo courtesy of the National Archives

1897

As maple flooring booms in factories, schools and post offices, the Maple Flooring Manufacturers Association is formed. (Read more about the history of maple flooring here.)

1898

The end matcher is invented and is soon employed at wood flooring manufacturing plants.

An Ohio floor layer installs a floor using a hammer in 1937. Photo courtesy of the Library of Congress.

An Ohio floor layer installs a floor using a hammer in 1937. Photo courtesy of the Library of Congress.

This hatchet belonged to wood floor pro Louis Armstrong, who used it to install flooring during his Memphis-area contracting career, which started in 1941. It was a common

This hatchet belonged to wood floor pro Louis Armstrong, who used it to install flooring during his Memphis-area contracting career, which started in 1941. It was a common

tool for manual floor installations at the time.

1900–1930

Floor plans begin to open up in American houses, meaning larger expanses of wood floors in new construction. Oak, chestnut, maple and birch floors are laid in uniform tongue-and-groove boards. Treating wood floors with stain, varnish and wax becomes commonplace. Darker floors are favored, and paint continues to be a popular coating for softwoods.

Flooring is cut by hand and blind-nailed by hand. Installers use a hatchet similar to a roofer's hatchet for nailing, with the head set at an angle. Other nailing tools include big straight-claw hammers, often a 16-ounce hammer for 3/8-inch flooring and a 20-ounce hammer for 3/4-inch flooring.

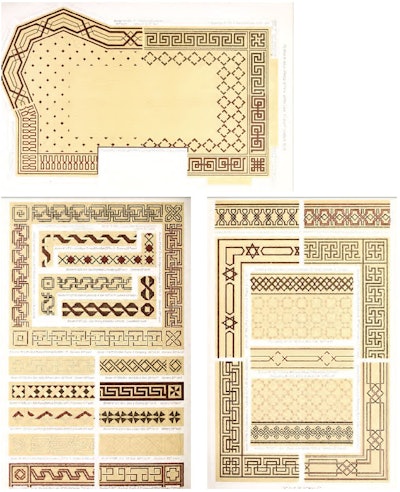

1901

Ornamental, face-nailed parquet flooring is a phenomenon. S.C. Johnson sells 5/16-inch parquet flooring in a wide array of patterns. (Flip through a catalog from 1901. Flip through another catalog from around the same time period.)

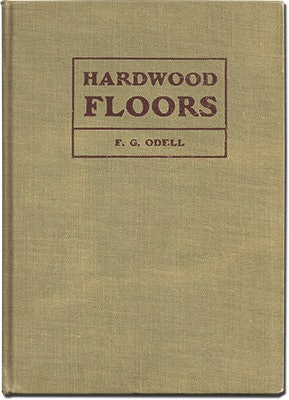

1906

F. G. Odell publishes "Hardwood Floors," a book containing advice and tips (many of them amusing) about the craft. (Flip through some of the pages here.) Resources for the hardwood flooring industry continue to expand.

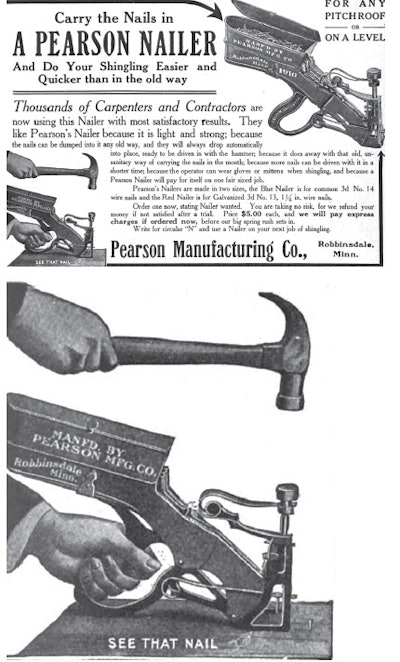

1908

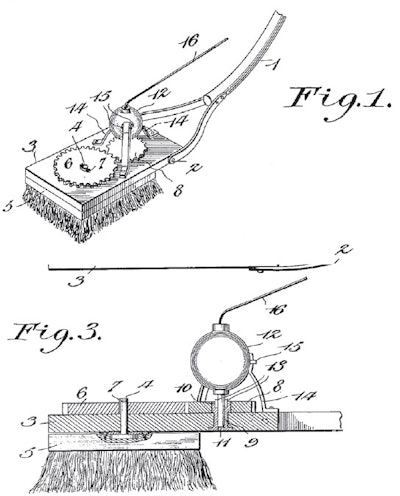

Martin Pearson of Robbinsdale, Minn., patents a handheld nailing tool that feeds nails into the path of a driving plunger, effectively spawning the first nailing machine. It becomes known as Pearson's Nailer.

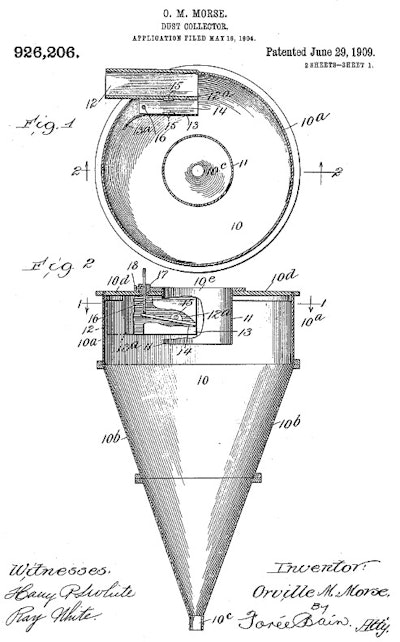

1909

Orville Morse of Jackson, Mich., patents a centrifugal (or "vortex") dust collector, a technology that will play a large part in wood flooring dust collection systems in the future.

1909

NOFMA, the National Oak Flooring Manufacturers Association, is founded in Chicago and establishes industry standards.

1909

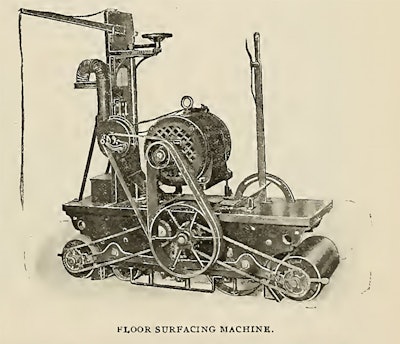

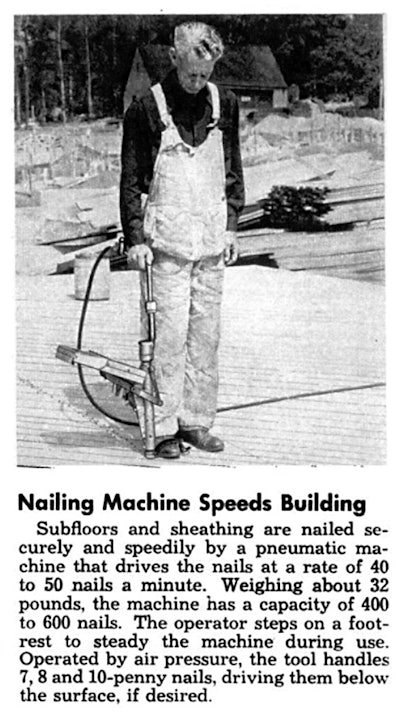

John H. Prugh of The American Floor Surfacing Machine Company in Toledo, Ohio, receives a patent for the first motorized floor sanding machine. A year prior to its patent, in 1908, the novel machine caught the eye of the Journal of Electricity, Power and Gas, which wrote: "This machine, the manufacturers claim, will do as much work as 20 men will do by hand, and besides, doing it much cheaper and better, and is rapidly creating a demand for surfaced floors, which will harmonize with the balance of the interior finish."

|

Lifelong wood flooring pro Bob Goldstein, now retired, recounts the origins of the first floor sanding machine: It was a mistake on a bid by the contractor who was building the Natural Science Building at Stanford University in Palo Alto, Calif., that led to the invention of the floor sanding machine. The contractor left out the cost of the wood floor "surfacing" and the mistake went unnoticed until the work schedule was laid out by the construction superintendent. Hand-scraping was the typical method to surface and finish wood floors at the time, and the cost of doing it would have been devastating to the company. "Necessity is the mother of invention" and the construction superintendent Mr. John H. Prugh, who had a good working knowledge of wood milling equipment, got permission to build a mechanical electric motor driven floor surfacing machine. The primitive machine weighed over 400 pounds with the operator standing on the machine. Prugh started a company he called the American Floor Surfacing Machine Company. His machine used a 5-hp motor and sandpaper that had been developed for the furniture manufacturing industry. It saved the construction company $4,000—a lot of money in the early 1900s. It did such a good job on the Oregon Pine floors compared with the look and cost of hand-scraping that word spread throughout the country and the world. In 1904 at the St. Louis World's Fair, the American Floor Surfacing Machine Company was awarded a bronze medal for the accomplishment of producing and exhibiting the world's first practical floor sanding machine: U.S. patent 928,154. |

1911

Edwin L. Bruce establishes the E.L. Bruce Company in Kansas City, Mo. It would go on to become one of the most prominent hardwood flooring manufacturers of the 20th century.

1916

Minwax, a company founded by Arthur B. Harrison two years earlier, develops a liquid brush-on paraffin for sealing stone. It is later adapted for wood floors. (Flip through a circa-1911 catalog outlining proper floor care and finishing materials.)

1919

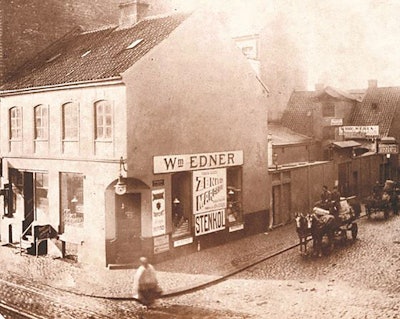

Wilhelm Edner, a coffee/grocery store owner in Malmö, Sweden, who sells his homemade floor wax under the name "Bonvax," incorporates the wooden floor care business as "Bona AB."

1921

John Howard of West New Brighton, N.Y., patents an "Electric Floor Mop or Brush," which will become a prototype for the buffer. "This invention relates to improvements in mops or floor brushes, and one of the objects is to provide a device of this kind with a motor for giving rotary motion to the tufted portion."

1931

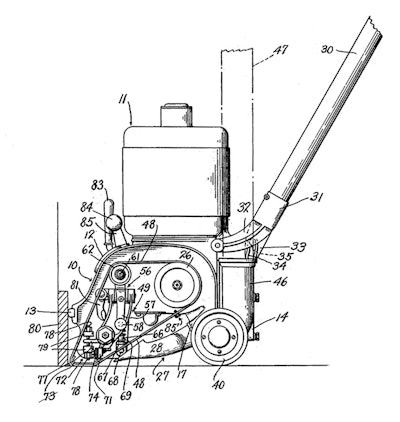

Robert G. Bruce of E.L Bruce Company receives a patent for a wood block floor that is sanded, scraped, waxed, polished and colored in his factory prior to installation. "That is to say, instead of laying the blocks in the condition of finish in which flooring is ordinarily laid, I do all the surface finishing before laying the blocks, and at the factory," he writes in his patent application in 1929. "A floor layer has merely to lay the blocks in position and the floor is immediately ready for use."

1931

The American Floor Surfacing Machine Company receives a patent for the first wood floor edger.

"In finishing around the marginal edge portions of a floor, the work is usually accomplished with a small hand tool," the company's patent application states. "This class of work is commonly referred to in the trade as 'hand jerking.' Having noted the inconvenience of such work and the laborious tasks encountered with the hand scraping tools on stair treads, doorways, small closets and the like, we have developed a comparatively small portable machine which overcomes the innumerable objections known to the trade."

1937

Dr. Otto Bayer discovers basic polyurethane chemistry, a chemical later utilized in flooring finishing products.

1938

Henry O. Anderson patents a flexible, open-mesh abrasive for Norton Company. His application stresses the importance of the abrasive having a weave with an open mesh. He is leaning toward using leno cloth as the backing material, but hasn't quite settled on it:

"So far as certain features of the invention are concerned I might use a cheese cloth or any open mesh cloth whether made with a plain weave or not…"

Screen-backed discs will go on to replace the thick steel wool pads used as abrasives.

1942

E.L. Bruce patents its mechanized factory-finishing process for its wood floor blocks. The company's 200-foot finish application line runs at a rate of 20 feet per minute. In advertising as early as 1938, the company hails its process as one that produces "the most uniform and dependable surface that hardwood flooring has ever had."

1943

Gustaf Kähr of Stockholm, Sweden-based AB Gustaf Kähr, a producer of wooden toys, furniture and flooring, receives a U.S. patent for the first modern engineered wood floor, a composite board structure made up of three layers of wood glued together.

1944

E.L. Bruce continues to improve its prefinished wood floor manufacturing efficiency, adding infrared lights to its finishing application line process. The addition increases the speed of manufacturing, as previously the finished and filled wood had to cure for a minimum of 12 hours before it could be waxed or polished, and even that time varied depending on humidity and temperature. "In the present invention," Watkins W. Partee and Milton Gray write in their patent application for the company, "the total time expended from the beginning to the end of the operation is about 12 minutes in one integral and continuous operation as compared to as much as three days by the prior process."

1947

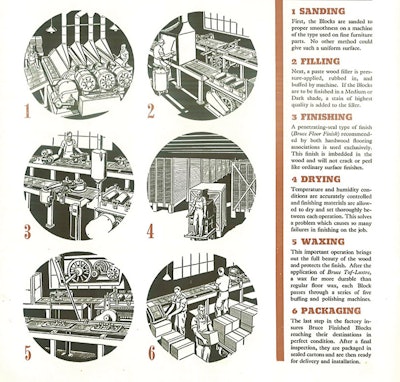

Edgar P., Carl J. and Dolly Anstett of Powernail Co. patent a portable nailing machine for floors.

|

The REO Clubhouse was the hot place to be in the 1940s in Lansing, Mich. The event space hosted free movies, wedding receptions, basketball games and balls. And pictured here sanding its well-trod floors in 1944 is Frank Garrage of Frank Garrage Floor Sanding. Garrage, born in 1907, ran one crew beginning in 1935 and worked until 1967, according to his great-grandson, fourth-generation wood floor pro Ken Hoffman. Garrage's son (Hoffman's grandfather) Gene worked with him as a teenager and went out on his own in 1958. In this photo, Garrage is using a floor sanding machine patented by The American Floor Surfacing Machine Company in 1937, which can also be seen in the above 1948 ad in Popular Mechanics. The REO Clubhouse was razed in 1979, nine years after Garrage passed away. Ken continues Garrage's legacy with his own company, Garrage Family Floor Sanding. |

1950

Morris Pynoos, a civil engineer, is credited with the design of the first nail gun, introducing pneumatic tools to the construction industry. The tool was developed while Pynoos worked on Howard Hughes' infamous H-4 Hercules flying boat (nicknamed the "Spruce Goose") in the 1940s.

1951

Arthur A. Cavanaugh of Alameda, Calif., patents his face-nailing machine, which will become known as the Cavanaugh nailer, with the objective of creating a nailing machine "which involves a minimum number of moving parts."

1953

Edgar P. Anstett of Powernail Co. patents the L-style flooring cleat.

1958

Parsons Corporation, a Traverse City, Mich., technology firm, patents a "motor controlled apparatus for positioning machine tool," the first CNC cutting machine. The technology eventually makes elaborately patterned floors, inlays and borders accessible for the average hardwood flooring professional.

1958

Powernail Co. receives a patent for its manual cleat nailing machine, a tool that would greatly increase the speed and efficiency with which wood floors could be installed.

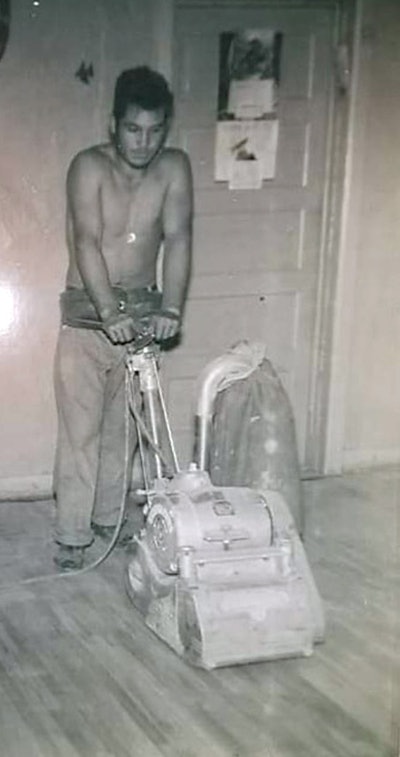

|

In this 1958 photo, Joe Martinez is 20 years old and three years into a hardwood flooring career that would span half a century, says Staci Martinez, co-owner of Sioux Falls, S.D.-based Phoenician Wood Floors and Joe's daughter-in-law. Joe worked for a number of hardwood flooring companies when he started out in 1955 in Phoenix specializing in commercial installation and sanding and finishing. He eventually founded his own company, Aztec Floors, and later Martinez and Sons. Three of his sons, Chris, Joseph of Phoenician Wood Floors and Mike of Phoenix-based True West Wood Floors, would follow him into the trade. Joe passed away in 2005, but not before imparting a lifetime of hardwood flooring knowledge to his family. "He used to reminisce with his sons about installing wood floors in houses before the interior walls went in and how they used to fill the floors with filler from gunny sacks and buff in the filler," says Staci. "The painters used to come in after and finish the floors." |

1960

Inventors at Minnesota Mining and Manufacturing Company in St. Paul, Minn., (later 3M), patent a low-density, open non-woven fibrous abrasive for flooring to compete with brushes and steel wool pads in use at the time. It's branded as Scotch-Brite.

1962

Norton Company patents its non-woven abrasive disc.

1963

Delmer Wagner, an electrician working for a sawmill in Redmond, Ore., invents the first in-line moisture detector using transistors. Two years later he founds his company, Wagner Electronic Products Inc., later Wagner Meters.

1966

The U.S. passes the Veterans' Readjustment Benefits Act of 1966, also known as the "Cold War GI Bill." The FHA law enables veterans to finance materials that will not last the lifetime of the mortgage, and subsequently changes the trajectory of the flooring industry.

|

Neil Moss, a former regional manager with Hartco in the 1970s and later with Armstrong Flooring, recalls the impact of the amendment: "In the 20 year period prior to 1970, if you wanted to get other than a VA loan, you got an FHA loan. And both the VA and the FHA back in those days required that whatever was included in your house mortgage had to be designed to last the life of the mortgage. But with this change, now you could finance your wall-to-wall carpeting. Well, the consequences of that is in the next decade almost 90 percent of the wood flooring manufacturers were out of business. And there weren't a whole lot of acquisitions. There were some acquisitions and consolidation over on the gymnasium side, but not on the residential side. There wasn't any money to consolidate with." |

1969

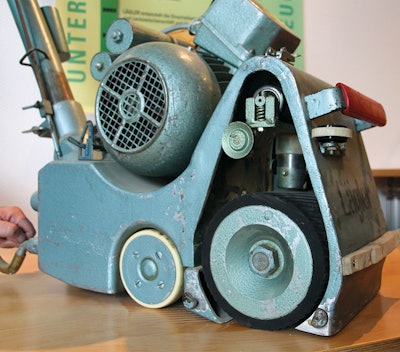

Eugen Lägler of Frauenzimmern, Germany, develops a portable belt sanding machine, dubbing it the "Hummel," which translates to "bumblebee." Up until this point, belt sanders were used in industrial settings, while drum sanders dominated job-site sanding.

1978

Triangle Pacific Corp. of Dallas, a cabinet maker, buys Bruce Hardwood Floors, formerly E.L. Bruce. Bruce spends the next decade becoming the largest producer of residential hardwood flooring in North America, and Triangle Pacific purchases more wood flooring manufacturers before being purchased by Armstrong World Industries in 1998.

1979

The NOFMA/APA/MFMA hardwood flooring installation school, the first national training program, begins in Memphis. (Read more about the history of NOFMA's training program here.)

Photo courtesy of Bona

Photo courtesy of Bona

1979

BonaKemi launches the first waterborne finish with its D-503 Pacific. Waterborne finishes usher in a new era for the global hardwood flooring industry.

1985

The National Wood Flooring Association is founded with a mission to increase awareness, sales, standards and professionalism within the industry. (Read more about the history of the NWFA here.)

1990

The World Floor Covering Association launches The International Surface Event, a flooring trade show that will become the largest of its kind in North America.

1990

BonaKemi offers stains featuring two-hour dry times for brown tones and 6-hours for white. Traditional oil stains have 6-12-hour dry times for brown tones and a minimum 72-hours for white.

1992

Maroon pads begin to be used between coats of waterborne finishes. The synthetic maroon pads better contour the surface.

1995

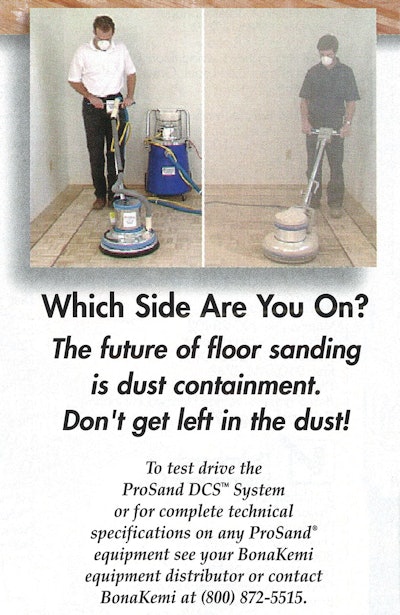

BonaKemi USA trademarks its DCS SuperVac, a dust containment system that addresses a longtime homeowner complaint and improves the air quality of wood flooring job sites.

1996

Anderson Hardwood Floors (Clinton, S.C.) and Kahrs International Inc. become some of the first flooring companies to foray into the World Wide Web, introducing their websites at Surfaces.

1997

Atlas Companies Inc., then-parent company of Basic Coatings in Des Moines, Iowa, trademarks "TyKote," the first finishing system to recoat a wood floor without abrading it.

1998

The NOFMA training school hosts a record 103 students.

1998

The U.S. Environmental Protection Agency issues new rules to reduce emissions of volatile organic compounds (VOCs) from architectural coatings, beginning an era of a patchwork of regulations throughout the U.S.

1999

Kährs introduces wood flooring with glueless joints. The technology enables faster installations.

1999

Dura Seal releases its Quick Dry Sealer and stain.

2003

BonaKemi introduces its Atomic DCS trailer.

2008

The NWFA and NOFMA consolidate under the NWFA name.

2008

The U.S. amends the Lacey Act to prohibit the import, export, sale or purchase of wood illegally logged anywhere in the world. (Read more details about the Lacey Act here.)

2018

The International Wood Flooring Association is founded and begins offering training.