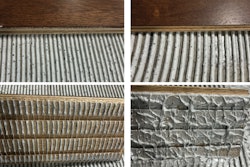

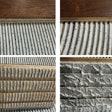

It's important to acclimate adhesives to normal temps so they don't have issues with spreadability, bond strength, spread rates and curing. (Photo courtesy of Bostik)

It's important to acclimate adhesives to normal temps so they don't have issues with spreadability, bond strength, spread rates and curing. (Photo courtesy of Bostik)

Do cold temperatures affect an adhesive's performance?

Chad Bulen, technical service director for Bostik's Consumer and Construction North America unit, based in Wauwatosa, Wis., answers:

Winter is coming, and with that means a few crucial reminders for installers who use adhesives in their projects. Colder temperatures affect many aspects on a job site, and below are two common things to think about.

Storage: Cold storage (below 50°F) of adhesives is not recommended. Although many adhesives today do not contain water, they are still susceptible to crystallization. Storing polyurethanes or modified-silane adhesives in a work truck overnight in the winter can significantly affect the product's workability and long-term performance. Cold adhesives, in general, are more difficult to spread, cure more slowly, contain lower bond strengths and yield lower spread rates. Remember to acclimate all material from cold storage, whether that's your work van/truck or your shop, to a warmer job site. It is often required to acclimate flooring on a job, so remember to acclimate your adhesives, as well.

Heat and lower RH: When colder temperatures hit, people start turning on the heat. Those heated job sites will have humidity levels that gradually decrease from summer levels. We all know that lower humidity causes shrinkage of flooring as the wood's moisture content decreases, but it can also affect the adhesive. Humidity from either concrete/substrates or atmospheric conditions is what triggers the curing reactions in "moisture-cured" adhesives. If humidity levels drop very low, an installer can expect longer cure times for the flooring installation. Very dry environments can be managed for optimal adhesive performance by tacking concrete/substrates with a dampened towel, which will introduce moisture to help curing.

RELATED: Sticky Questions: Q&As on Essential Adhesive Know-How