Hello all, Keith Long here with Thunderheart Flooring, based out of Greeley, Colo., to carry on with the production of the pinwheel parquet squares installed in Moberly, Mo.

The main reason I do these blog posts is to convey information, with the hope that those reading will gain the confidence to try new techniques. It seems that no matter what project I’m involved with, I look at the scope of work first. Next, I break the scope of work down into its simplest forms. Then, I decide which order I will perform the work in. Then, I do it. At the end of the Jigs and Medallions course I took, Frank Kroupa, the lead instructor, said to the class, “You’ve gained some newfound skills during this course. It would be a real disappointment if you didn’t do anything with it. I encourage each of you to get out there, and put your skills into practice.”

When complete with this parquet square project, I took one piece of each dimension that comprised the pattern for a template. Robin (my wife) wrote in Sharpie on the back of each piece how many of that dimension it took to make one parquet square, drilled a hole in each, and ran a cord through to bind them together. The next time we do this pattern, all of this work is complete, and we won’t have to “reinvent the wheel” to arrive at our dimensions and quantities.

For the longer pieces of the pattern, I set up this extremely low-tech type of stop block. These pieces were being cut from lengths up to 9 feet (almost 3 meters) long, so it wasn’t practical to run them through a sliding table saw jig. Also, it wasn’t necessary—a stop block performed just fine. I was careful to keep the area on the miter saw free of dust and debris as I cut.

Since I had already calculated how many of each piece per square and how many squares were needed, I knew the quantities to cut before changing the stop block distance to produce the next dimension of piece.

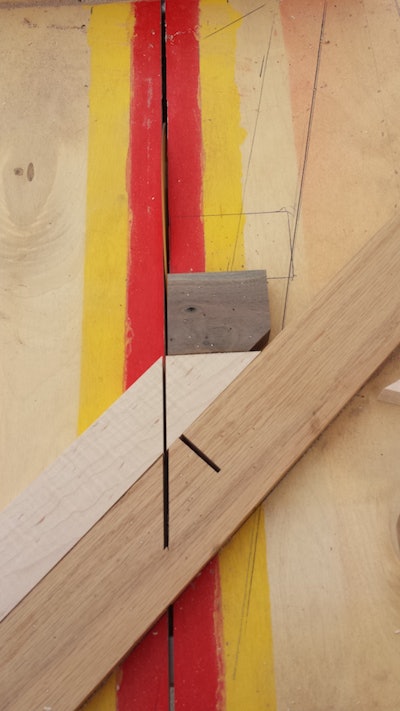

This is what I refer to as a sliding table saw jig. It can come in extremely handy for producing pieces exactly the same size, over and over again. I made this one out of Baltic birch plywood a few years ago, with the help of Bob Humphreys and Frank Kroupa. They showed me how to build a handle on the front, a support along the back for stability, and the two strips of Baltic birch along the underside that run in the channels of the table saw.

These sorts of jigs are great for production work that needs to be precise. They are also wonderful for getting small pieces cut in a safe manner. Once the jig slides without play on the table saw, the blade is raised up through the plywood, and the jig gets passed through once to create the space where the blade will always pass. Once stock is set in place, I am vigilant about making sure the table saw blade is just high enough to make the cut needed. Having it any higher is unnecessary, and could cause serious injury if it came into contact with me. I only work at a speed fast enough to safely make cuts on these sliding table saw jigs. That being said, if they are built correctly and move without much resistance, a lot of work can be produced with them in relatively short periods of time.

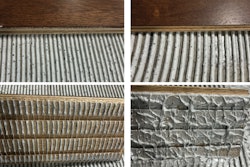

With 23-gauge headless pin nails, I fastened these two pieces onto the jig. After some fine adjustments, running the maple and walnut through produced the pieces for the pinwheels. I cut, while Robin made a gluing jig for the pieces to be glued up into pinwheels.

She made the sides of this jig out of thinner stock than the flooring, then left the one side open, for ease of exit once the pinwheels were glued and taped. She used Titebond (yellow glue) to side-bond these pieces, then used blue tape to keep them together until the glue dried. Once two were glued up and taped, she would take the first one out, and glue and tape another. Back and forth, back and forth …

I had friends on the wrestling team in high school. They would wear overshirts to their meets that read, "Pain is temporary, pride is forever." It’s not even that cutting and fitting all these pieces is painful, just time-consuming, and detail-oriented. I personally found it to be a fun activity, and enjoyed it. I wonder to myself sometimes, if my great grandchildren were to ask my daughter what her father was like, what would I rather hear her say:

1. He did the bare minimum to get by in life, and never showed an interest in what I was involved in. He pumped out lots of straight, cookie-cutter hardwood floors. He was always looking for ways to cut corners, but still get paid. It was a challenge for him to make enough to support us—we never had much and never took trips anywhere. He was extremely attentive to his vices, and could stare at the television for hours on end.

2. He was a motivated, driven man who loved me. He attended all my concerts and plays when I was a child. If I asked for something, and it was reasonable, he and my mother said yes. My parents took me to see the world and talked with me about every subject under the sun as they raised me. They taught me many positive things. Your great-grandfather built some of the most beautiful houses, they are considered works of art. He loved helping others. He was an extraordinary man—I wish you could have met him.

I’m living my life in a way I imagine would lead my daughter to tell version No. 2.

Let’s pick it up again next week as we get gluing jigs built for these parquet pieces and put them together.

Until then, stay sharp!