Installing wood flooring may not be rocket science, but there's a lot that can go wrong anyway. Different job sites, changing moisture conditions and difficult customers can all make day-to-day life as a contractor more ... well, challenging. Throw a multitude of exotic species into the mix, and the likelihood of problems seems to increase exponentially. Sourced from all corners of the Earth, today's wood flooring doesn't always behave the way we expect wood flooring to, and that can cause major headaches. Here are some of the most common reasons contractors get called back to the job site after installing exotics, and how to (try to) avoid them in the first place.

Color Change

Common species: Brazilian cherry/jatoba, tigerwood (shown), many others

What to do about it: There's no way to prevent color change. Educate the customer when they are considering a species known to drastically change color. Provide them with samples showing what the species looks like new and after aging. After the fact, the best answer is to simply let the previously covered area "catch up" to the rest of the floor. If the customer can't wait that long, resanding is the only option (although in some severe cases, even resanding won't fix it). If a floor needs to be covered on a job site to protect it from other trades, be sure every square inch of the floor is covered. If customers won't accept the appearance of a single board, board replacement may be the only option.

Color Variation

Common species: Many (timborana shown)

What to do about it: Be sure you show customers an accurate representation of the species, not just a small sample. Be clear on what the manufacturer's proprietary grading rules are so you know what to expect from the product you order. And be sure you're buying product from a reputable manufacturer-one that is more likely to have its own reliable grading standards.

White Spots

What it is: White spots that appear over time-often months after the floor has been sanded and finished.

Common species: Brazilian cherry/jatoba (stair tread shown on left), Brazilian teak/cumaru (shown at right), tigerwood

Some contractors educate customers ahead of time about the spots, others simply hope they don't occur and still others just avoid installing species prone to the white spots. If customers object once the spots have appeared, most contractors opt for board replacement.

With factory-finished flooring, the spots may or may not be allowed per the manufacturer's grading rules.

RELATED: How to Prevent Cupping and Worse in Summer Months

Gapping and Cupping

Adding to potential moisture problems is the fact that most exotics originate in much more humid climates. When they are installed at a much higher moisture content (MC) than they will have over time, permanent gaps in the floor will appear.

With engineered products, cupping often occurs when the flooring is installed in a low relative humidity (RH) environment.

Common species: Any (floor shown with gapping is Brazilian teak/cumaru; cupped floor is Brazilian cherry/jatoba)

Experiment with which fastener to use, the angle and the pressure so that tongues don't crack. Some species are so hard that predrilling is the only effective way to fasten them.

For engineered flooring, maintain RH at an acceptable level for that product. If you know the RH will get too low, a different product may be necessary.

RELATED: How to Prevent Wood Floor Gaps in Winter

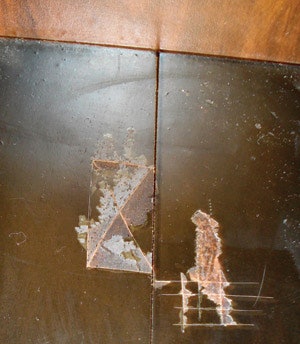

Face-Checking

What it is: Long cracks in the veneer that run along the length of the board in engineered flooring. It typically occurs when flooring is manufactured at a higher MC and installed where it will be exposed to much lower relative humidity (RH). As the veneer dries, it is held in place by the glue and fractures as it shrinks.

Different manufacturing problems, such as the face veneer and core veneer being manufactured at different MC levels or having different dimensional change coefficients, can make this issue even worse. Rotary peeled veneer will face-check more easily than a sliced veneer. A sawn face, if very thick (3.5 to 4 mm), can also tend to face-check if not well-controlled by humidity levels being maintained in the home.

What to do about it: Again, many exotic products are manufactured abroad with a much higher MC than they will have once they're installed on the job site. Be sure you buy from a reputable manufacturer, and be especially wary if the installed floor will experience low RH either year-round or seasonally.

RELATED: Engineered 101: Understand the Fundamentals of Engineered Wood Flooring

Finish Adhesion (Lack Thereof)

What it is: The finish or stain won't adhere well to the floor due to the oily nature of the wood.

Common species: Many (stained Brazilian walnut/ipé floor shown)

Sources for this story included: Howard Brickman, Brickman Consulting; Rick Jones, Swiff-Train Company; Mickey Moore, Wood Flooring Advisors; Roy Reichow, National Wood Floor Consultants Inc.; and Rusty Swindoll, NWFA.